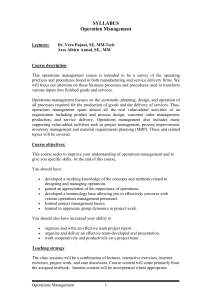

Manufacturing Resource Planning Distribusi Obat dan Alat Kesehatan Oktavia Eka Puspita, M.Sc., Apt. PSPA Jurusan Farmasi FKUB Manufacturing Resource Planning Distribusi Obat dan Alat Kesehatan? Business Information System Sistem perencanaan manufaktur dan sistem kontrol terintegrasi Mekanisme koordinasi pemasaran, keuangan, produksi, dan departemen lain dalam perusahaan Manufacturing resource plan” (MRP II) vs “materials requirement plan” (MRP) What are the core information systems a business firm needs today? What do these systems do, and how can they be used effectively? Software for material requirements planning (MRP)—so-called MRP systems or MRP packages. The core of MRP was planning the material requirements that corresponded to a given production program. The fundamental questions in MRP were as follows: (1) Which materials and which quantities of these materials (= secondary or derived requirements) are needed to produce a given production program (= primary requirements)? (2) How can the material requirements be fulfilled? • Required a great deal of computation and the consideration of many details. • Complex structure of industrial products • Large number of items contained in real-world bills of materials • Benefited from MRP systems computational effort to calculate was substantially reduced good material planning • Good material planning is not the same as good production planning. • It is a necessary but not a sufficient condition for a good production plan • Producing the planned quantities of all materials within the given time period is only possible if the production capacities are available exactly at the times when they are needed. • This means, for example, that the right machines must be available whenever production orders request them. • Since machine loading and scheduling of production orders are not considered during material requirements planning, it is highly unlikely that capacities will be available at the time that they are needed. Apa yang menjadi prioritas (priority) – berapa banyak sesuatu yang harus diproduksi dan kapan? Kapasitas apa yang tersedia (available capacity)– sumber daya apa yang kita miliki? • The outcome of material requirements planning is quantities—primary and secondary requirements assigned to different periods. • The main disadvantage of the MRP approach is that it is not certain whether the requirements can be fulfilled, because the manufacturing capacities are not taken into consideration. • In order to create a feasible plan, material requirements planning has to be augmented with capacity planning and scheduling. MRP Closed Loop MRP & MRP II • Including capacity requirements planning and scheduling of production orders into the planning approach. • MRP II, according to its founder Oliver Wight, is an abbreviation of manufacturing resource planning (no longer of material requirements planning), • Indicating that all necessary resources have to be considered in the planning, not only the materials. • MRP II is a comprehensive market and resource oriented planning of the sales, production and stock levels, which begins at the executive level” • MRP II system became the firm’s core information system, • supporting not only the planning and controlling of materials, capacities, and production orders • but also other business areas such as procurement, cost calculation, sales, and production data acquisition Contoh Alur Data Input MRP Sales and operations planning—establishes the end-product quantities to be produced in each period up to the planning horizon, usually on an aggregate level (e.g., by product groups or families). Master production scheduling—breaks down the aggregate numbers of the sales and operations plan into quantities of individual products. Material requirements planning—calculates the secondary requirements Capacity requirements planning—determines how much capacity of the operating facilities and workplaces is needed to fulfill the quantity requirements and schedules the capacity requirements Realistic?—this question is the core of closed loop MRP. If the plan is not realistic, adjustments must be made so that the capacity, materials, master production, and/or sales and operation plans become feasible. Executing capacity and material plans—generating feedback and if necessary,making adjustments to the material and/or capacity plans. THANK YOU