Uploaded by

common.user52104

Repairing Corrosion-Damaged Reinforced Concrete Structures

advertisement

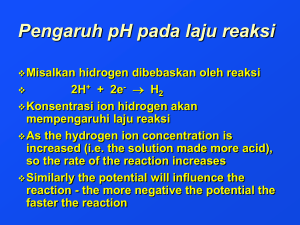

Maintenance of Civil Engineering Structure Repairing Method for Corrosion-damaged Reinforced Concrete Structures Silmi Kaffah and Asdam Tambusay Civil Engineering Department, Faculty of Civil, Planning, and Geo Engineering, Sepuluh Nopember Institut of Technology Abstract Corrosion of reinforcement concrete structures are becoming well understood. The continuous corrosion process does not only affect in structural serviceability by racking or even spalling the concrete cover. The physical effects of corrosion includes loss of bond strength between steel reinforcing bars and concrete, loss of steel area, and due to cracking reduce of concrete strength. In this paper, details of corrosion mechanisms, which include initation and propagation, and the parameters which contribute to the corrosion process are described. This paper also proposed non-destructive test to know the status corrosion in reinforced concrete, such as hammer tests, half-cell potential tests, and chloride level tests. Furthermore, this paper proposed repair strategies, e.g. patch repair, coating systems, cathodic protection, and paint reinforcement. Keywords: corrosion, reinforced concrete, corrosion mechanism, non-destructive tests, appropiate techniques comparatively new. One of the most causes of the failures of concrete structures is either the structures were not durable enough or appropiate in concrete. Since then, chloride-induced corrosion has become more important for structures exposed to chloridecontaining environments (FrancoLujan, Maldonado-Garcia, MendozaRangel, & Montes-Garcia, 2019). This study reviews the corrosion of reinforcement concrete. The following sections give fundamental information on the corrosion process of steel in concrete. There are three steps will be described. First, determine the process of corrosion which the reinforcement concrete member will exhibit signs of corrosion in the reinforcement. After that, propose potential methods to further investigate the current condition of the structure. And the last is delivery appropiate techniques of monitoring and maintenance will be analyzed. 1. Introduction The reinforced concrete is one of the most important construction materials, which has been mostly used in infrastructure construction. However, the durability problem which causing premature deterioration in reinforced concrete is increasing. The steel rebar corrosion has been one of the most important concrete durability deterioration and decrease of bearing capacity of the infrastrutures. To ensure the reliable service, it is significance to develop the affective monitoring techniques. It is known that electrochemical corrosion process usually causes the corrosion of reinforcing steel.. Corrosion of steel in reinforced concrete structures are becoming well understood. However, many existing concrete structures show significant corrosion. The structure is needing expensive repair although it is 1 Maintenance of Civil Engineering Structure reaches a critical concentration values required to damage the protective layer on the surface of steel reinforcement. There will be a process of corrosion when oxygen (O2) and water (H2O) on the metal surface is in sufficient quantity. There is no decline in the strength of concrete structures during the initiation of corrosion as rebar corrosion has not started yet. The next phase is corrosion propagiation. Corrososion propagiation is the process of reducing crosssectional area of reinforcement steel. The decrease of strength of reinforced concrete structures begins at this stage. The whole stage of corrosion can be seen in Figure 2. 2. Research Significance Since reinforced concrete has been the mostly used because reinforcement helps concrete in tension, the durability and longevity of the concrete due to the corrosion potential of the reinforcement are be a concern using this practice. Corrosion of steel in reinforced concrete is the number one cause of failure. Many existing concrete structures show significant corrosion which need expensive repair. In most cases, either the structures were not durable enough or the appropiate maintenance had been neglected. Corrosion of the reinforcement concrete embedded in concrete causes most of the failures of concrete structures. Here is the example of reinforced concrete beam which having damage due to corrosion (Figure 1). Figure 2. The Whole Stage of Corrosion The high alkalinity of the concrete pore water (pH over 12.5) that reduces the corrosion attack to negligible values leads to a passive layer forming on the steel. Corrosion will not occur as long as this passive layer is sustained. Two processes which may destroy this protection layer are: Carbonation of concrete Chloride attack Corrosion of the reinforcing steel can show different forms. General corrosion which mostly in cases of carbonated concrete, leads to early cracking and spalling of the concrete, often with comparatively little reduction of the cross-section of the steel reinforcement (Figure 3a and b). Figure 1. Reinforced Concrete Beam which Having Damage due to Corrosion 3. Work Flow Description 3.1 Corrosion Mechanism in Concrete Corrosion of reinforced concrete structures can be devided into two phases, they are corrosion initiation and corrosion propagation. Corrosion initiation starts when chloride (Cl) penetrates into concrete reaches the reinforcing steel (rebar) position. The concentration of chloride on reinforcing steel increases with time, until it 2 Maintenance of Civil Engineering Structure Whereas due to chloride ions, the localized corrosion results in pits may be large before signs of deterioration of the concrete surface can be seen. per unit of time or as current density (current per unit area). 3.2 The Cause of Damage The main consequences of corrosion in reinforcement steel include loss of corrosion section of rebar area, spalling and delaminating concrete cover. Thus, the bond strength between the steel reinforcing bar and concrete is reduced, and the strength of the structure is deteriorated. Several factors which influence the corrosion potential of steel reinforcement such as moisture intrusion, quality of the concrete and construction materials, lowered pH values over time, initial curing conditions and the formation of cracks in the concrete, and proper concrete coverage of steel reinforcement. Because of these factors, chloride movement can speed up into the concrete, disrupting the protective oxide film around the reinforcing steel and leading to rusting. This corrosion can reduce tensile capacity and lead to spalling and delamination of the concrete structure. In any type of concrete, including ordinary, self-compacting or lightweight concrete, chloride attacks are the most detrimental to rebar. Recently, in the last 10 to 15 years, the use of lightweight concrete in construction has increased. One of the major causes of damage in reinforced concrete consider chloride-induced corrosion. (a) (b) Figure 3. Corrosion of Reinforced Concrete. (a) Spalling Concrete due to Carbonation and Chloride Ions; (b) Heaviliy Corroded and Cracked due to ChlorideInduced Corrosion Corrosion is an electrochemical process (Bohni, 2005). For steel in concrete, the following reactions occur: Anodic reaction: 2Fe → 2Fe2+ + 4e(1) Cathodic reaction: O2 + 2H2O + 4e- → 4OH(2) Sum of the reaction: 2Fe + 2H2O + O2 → 2Fe(OH)2 (3) The anodic reaction represents the dissolution of the metal (Hans Bohni, 2005). The flux of ions and electrons respectively can be taken as a measure of the corrosion rate. This can be given as mass lost per unit of time and area, as reduction of the thickness 3.3 Evaluate the Damage When corrosion of reinforcing steel develops significantly, the corrosive section expand continuously around the steel bar and generate 3 Maintenance of Civil Engineering Structure internal pressure to concrete. The continuous corrosion process of reinforcing steel does not only affect in structural serviceability by cracking or even spalling the concrete cover. By decreasing the loss-bearing capacity, corrosion of reinforcing steel also give serious impact on the structural safety. Besides, the physical effects of corrosion include loss of bond strength between steel reinforcing bars and concrete, loss of steel area, and due to cracking reduce of concrete strength. Therefore, evaluation the cause of damage is needed. It aims to find out how much damage occurs in reinforced concrete and how this damage affects the structure. duration for measurement, not destructive) one non- 4.1 Visual Observation Visual observation is the easiest and most effective method because it involves the simple inspections of wheter or not the steel corrodes in a structure to observatios damage in a concrete specimen. A detailed analysis is almost always destructive as the steel reinforcement must be removed from its environment. Visual observation was carried out to record any damages that occurred in the existing structures such as crack, delamination, and any rust stains should be noted (Bentur, Diamond, & Berke, 2005). In order to check for the presence of cracks, visual and microscopic observations were made. The cracks formed were not only caused by rebar corrosion, but also the dimention of the structure such as length and thickness. Due to the restraining effect of the adjacent elements, the cracks may form. Lower concrete quality may affect the formation of cracks. Cracks have formed at the weakest location by indicating the crack mapping of the structure. 4. Potential Methods It is necessary to know the exact place and the extent of corrosion attacks at the reinforcement in order to estimate the necessity of repair work. Corrosion sites have to be identified rapidly, non-destructively, and over the entire surface. Potential mapping is used during three stages of bridge maintenance: During inspection (basis for the repair concept) During repair work After repair work (quality assurance, monitoring) With the different methods for corrosion monitoring one can differentiate between local measurements and cover-all. Local information can be derived from the following: Built-in the structure (sensors, reference electrodes) Mobil structures, but these however are not suitable for cover-all measurements (high 4.2 Non-Destructive Testing (NDT) The status of corrosion in reinforced concrete member by using Non-Destructive Test (NDT). Those zones where the reinforcement is actively corroding should be determined by means of nondestructive electrochemical techniques such as corrosion rate mapping and corrosion potential. The use of nondestructive testing and/or analytical 4 Maintenance of Civil Engineering Structure formulation can represent rapid and high quality methods to evaluate the corrosion penetration of steel reinforcement. During the inspection, nondestructive tests were carried out. The corrosion behaviour of the steel reinforcement was insvestigated. From a sructural point of view, it is important to evaluate the reduction of cross-sectional area of reinforcing steel by using non-destructive tests. An analytical model to calculate corrosion of steel reinforcement by measuring external crack widths was proposed, in the case of both linear and non-linear concrete behaviour. Usually previous models avaliable in scientific literature were empirical in nature and governed by main parameters influencing the crack opening like as bar diameter, concrete cover, and concrete properties. pinpointed by using this test, and the destructive test can be directed at the designated location (Bayuaji, et al., 2018). The probability of corrosion in reinforcing steel can indicate by the potential value. The test is limited by the fact that a direct connection to the steel reinforcement has to be made. Typically, HCP readings are taken, which is inside the concrete at a depth varying according to the designed cover depth (Paul & Babafemi , 2018). 4.2.3 Chloride Level Tests Level of chloride in reinforced concrete at the reinforcing steel determines the time to corrosion initiation. The corrosion is assumed to initiate and start to reduce the crosssection of steel reinforcement. Further, the most important finding from this test was that the chloride level of concrete samples at the concrete surface at the splash and tidal zones did not give the highest chloride level. This is probably caused by a relatively high compressive strength. 4.2.1 Hammer Tests Hammer tests is a nondestructive testing method of concrete which provide compressive strength of the reinforced concrete. Hammer test estimates concrete strength based on surface hardness. The uniformity of concrete strength and concrete quality can be determined with ASTM C805/C805M-13a. The hammer tests result and compressive strength can be correlated to get the estimate concrete compressive stregths at hammer test location. 5. Appropiate Techniques In the future, the number of reinforced concrete structures that have online monitoring devices will increase. This is because continuous corrosion of steel reinforcement monitoring provides an early warning system and accurately timed repair measures can lead to a significant reduction of maintenance costs. The continuous monitoring of the corrosion of reinforcing steel in concrete structures has proved to be a powerful tool for determining the state of corrosion. Other than that, the continuous monitoring estimates the 4.2.2 Half-Cell Potential Tests (HCP Tests) The half-cell potential (HCP) is a standard test to determine the corrosion activity of steel reinforcement. The possible location of corroded reinforcing steel can be 5 Maintenance of Civil Engineering Structure expected lifetime in structure, determines the critical period for repairing, evaluates repair efficiency, and prove to be a powerful tool in testing the effectiveness of reconstruction measures. Figure 1. shows beam which have damage caused by spalling concrete and exposed reinforcing steel indicate serious deterioration. This beam is constructed with a very thin cover concrete, while the structure exposed to high chloride and velocity waterflow environment. the same diameter either by welding 10 cm length to the existing reinforcing steel 5.2 Coating Systems In order to prevent or stop corrosion in structural beams, there are several way such as with coating which a way of preventing these failures that can detect and heal localized corrosion. The best choices partly depend on the source of the corrosion. Water soluble particles can cause fast deterioration problem. That means surfaces must be free all pollutants before coating. Before beams are shipped, coatings are applied. This is usually done in enclosed workshops. If necessary, more coating materials can be applied later. The aplication of a hydrophobic coating (sometimes referred to as penetrant pore-liners) may be used to reduce the moisture content of reinforecd concrete and thereby electrolytically stifle the corrosion reaction. 5.1 Patch Repair Patch repair method is widely used to restore the original conditions of concrete structures. The patch repair concrete must be completely chloridefree and similar in characteristics to the concrete to be replaced. 5.1.1 Removal of Cracked and Delaminated Concrete By using a marker pen, delimit the area of damage. Break the delimited area until reaching sound steel and concrete. Saw-cut 2 cm deep in 90° angle the perimeter of breaking with a jack hammer. All damaged, weak, and easily removable concrete chipped away. If the rebars partially exposed after all unsound concrete is removed, it may not be necessary to remove additional concrete. 5.3 Cathodic Protection Cathodic protection is the main alternative to patch repair. It is because although patch repairs remove the contaminated concrete from the deteriorating areas, they may address other sections of hidden corrosion. Impressed Current Cathodic Protection (ICCP) is a technique that sends a small electrical current through the concrete to the reinforcing steel in order to stop the corrosion of the steel. The benefit of ICCP is that the extend of concrete removal for repair is reduced vastly. Once cathodic protection is installed, it can control the ongoing corrosion for the long term, with future spalling and deterioration eliminated even in 5.1.2 Cleaning of Corroded Reinforcement Clean steel reinforcement with a mechanical wire brushing or by sand blasting. The steel reinforcement which are corroded and have lost more than 25% of their diameter, they have to be cut and removed. Removed rebar should be replaced with new rebar of 6 Maintenance of Civil Engineering Structure concrete that is severely contaminated with carbonation or chlorides. The anodic reaction represents the dissolution of the metal. The flux of ions and electrons respectively can be taken as a measure of the corrosion rate. When the corrosion of reinforcing steel develops significantly, the corrosive area expands continuously around the steel bar and generate internal pressure to concrete. The physical effects of corrosion include loss of bond strength between steel reinforcing bars and concrete, loss of steel area. Therefore, evaluation the cause of damage is needed. It it necessary to know the exact place and the extend of corrosion at reinforcement concrete. This paper proposed non-destructive test to know the status of corrosion in reinforced concrete: (1) hammer tests which estimates compressive strength and concrete quality based on surface hardness, (2) half-cell potential tests is a standard test to determine the corrosion activity of steel reinforcement, the possible location of corroded reinforcing steel can be pinpointed, (3) chloride level tests, the chloride level of concrete at the rebar determines the time to corrosion initation. Numerous repair options are available and new technologies continue to make an impact in the field of concrete repairs (Mackechnie & Alexander, 2001). This paper proposed repair strategies: (1) patch repair includes removal of cracked and delaminated concrete and cleaning of corroded reinforcement, (2) coating systems which is a way of preventing the failures that can detect and heal localized corrosion, (3) cathodic 5.4 Paint Reinforcement For the greatest durabilty, the longest life to first maintenance starts with beams that have received a thermal metal spray or hot-fip galvanized structural beams. The beams would get a sealing coat of painting. Paint the reinforcing steel with anti-corrosion paint. A medium to long life if structures is delivered by high performance paint systems. In tough environments, paint systems based on drying oils are appropiate for short life. If the original finish, a thicker coating can also extend durability. So, one or two coats may be enough for reinforcing steel that’s been blast-cleaned. 6. Conclusions In this paper, details of corrosion mechanisms, which include initiation and propagation, and the parameters which contribute to the corrosion process are described. Corrosion initiation begins and reaches the reinforcing steel position. There will be a process of corrosion when oxygen (O2) and water (H2O) on the metal surface. Whereas corrosion propagation is the process of reducing cross-sectional area of reinforcement steel. The corrosion is an electrochemical process. For steel in concrete, the following reactions occur: Anodic reaction : 2Fe → 2Fe+ + 4e(1) Cathodic reaction : O2 + 2H2O + 4e → 4OH (2) Sum of the reaction : 2Fe + 2H2O + O2 → 2Fe(OH)2 (3) 7 Maintenance of Civil Engineering Structure protection is a technique that sends a small electrical current through the concrete to the reinforcing steel, (4) paint the reinforcing steel with anticorrosion paint. 7. References Bayuaji, R., Darmawan, M. S., Husin, N. A., Anugraha, R. B., Budipriyanto, A., & Stewart, M. G. (2018). Corrosion Damage Assessment of a Reinforced Concrete Canal Structure of Power Plant After 20 Years of Exposure in a Marine Environment. Engineering Failure Analysis. Bentur, A., Diamond, S., & Berke, N. S. (2005). Steel Corrosion in Concrete . London. Bohni, H. (2005). Corrosion in Reinforced Concrete Structures. England. Franco-Lujan, V. A., MaldonadoGarcia, M. A., Mendoza-Rangel, J. M., & Montes-Garcia, P. (2019). Chloride-induced Reinforcing Steel Corrosion in Ternary Concretes Containing Fly Ash and Untreated Sugarcane Bagasse Ash. Construction and Building Materials. Mackechnie, J., & Alexander, M. (2001). Repair Principles for Corrosion-damaged Reinforces Concrete Structures. Cape Town. Paul, S. C., & Babafemi , A. J. (2018). A Review on Reinforcement Corrosion Mechanism. Civil Engineering Research Journal. 8