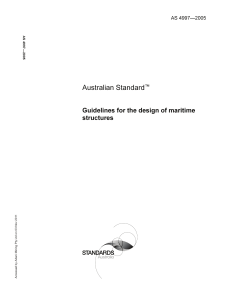

15 Meter Bridge's Steel Girder Displacement Check A. Structure Model The steel girder of 15 Meter bridge will be checked for displacement during construction stage. The construction stage will be as follow : 1. Stage 1 : Steel girder placement on the position 2. Stage 2 : Steel deck placement on top of girder stage 3. Stage 3 : Concrete pouring The girder will be analyzed using FEM by STAAD Pro v 8.i. The plate thickness follows the design thickness in the Shop DWG, the chamber is considered also in the model. The support will be assigned in the fixed part as pinned support and in the moved part as fixed but release longitudinal direction, bending moment in major axes. The girder model will be as follow : Page 1 of 4 Page 2 of 4 B. Loading The loading from construction stage will be as follow : 1. Girder selfweight (SW) The STAAD Pro will calculate the steel selfweight. The 5% weight is added to consider the splice plate, bolt and shear connector attached to steel girder. 2. Steel deck weight (DLS) The steel deck weight is applied ( 1 SHT 566DECK5 is 0.59kN) to the top flange and will be calculated as follow : Steel deck weight = 0.59*15/0.25/15 = 2.36 kPa 3. Concrete slab (DLC) The concrete slab weight is applied ( 0.4 m thickness and 1.8 meter width with density 24 kN/m3) to the top flange and will be calculated as follow : Concrete slab weight = 0.4*1.8*15*24/0.25/15 = 69.12 kPa 4. Uniform Temperature (TU) From SNI 1725 - 2016 the difference between average maximum temperature to minimum temperature for steel plate is about 30 deg C. This is will be an input for uniform temperature. C. Loading Combination The loading combination will reflect the construction stage where the previous load will be an addition to the next loading stage. Loading Combination 5 = SW + TU Loading Combination 6 = SW + DLS + TU Loading Combination 7 = SW + DLS + DLC + TU D. Result The maximum displacement of end girder to X direction will be checked for A.2 position as follow : Max X Min X Max X Min X Max X Min X Max X Min X Node 30 26 20 217 20 217 20 1 L/C 4 LOAD CASE 4 4 LOAD CASE 4 5 COMBINATION LOAD CASE 5 5 COMBINATION LOAD CASE 5 6 COMBINATION LOAD CASE 6 6 COMBINATION LOAD CASE 6 7 COMBINATION LOAD CASE 7 7 COMBINATION LOAD CASE 7 Horizontal X mm 5.48 -0.093 5.833 -0.001 5.957 -0.001 9.148 0 Vertical Y mm 3.749 3.749 0 -0.035 0 -0.041 0 0 Horizontal Z mm 12.099 12.139 0 -0.026 0 -0.026 0 0 The maximum displacement for X direction is from loading combination 7 which consider total dead load loading and uniform temperature loading is 9.148 mm while X maximum displacement of temperature loading only is 5.48 mm. Hence the displacement from total dead load is 3.668 mm. Page 3 of 4 The displacement model of end steel girder at A.2 (the displacement model red line has been magnified 100 mm/m for easy observation to differentiate with the initial unloaded model in green line) will be as follow: Page 4 of 4