Uploaded by

common.user42837

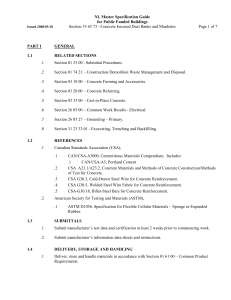

Corrosion Control in Concrete Structures: Materials & Methods

advertisement