Uploaded by

common.user148316

Design of Operable Reactive Distillation Columns PhD Thesis

advertisement

Design of Operable Reactive Distillation

Columns

Myrian Andrea Schenk

A thesis submitted for the degree of Doctor of Philosophy

London.

University

the

of

of

Department of Chemical Engineering

University College London,

London WClE 7JE

September, 1999

It.

Abstract

Reactive distillation is an integrated process which considers simultaneous

physical and chemical transformations. It is increasingly receiving attention

both from industry and academia. Significant advances have been made in

the area of modelling and simulation as well as the implementation of such

industrially.

However,

the area of control and optimisation of such

units

has

been

units

not

explored thoroughly.

The thesis presents a general framework for simulation and design, which can

handle reactive and non-reactive systems. Various different aspects of the

distillation

described

have

been

in

modelling and simulation of

order to understand the behaviour of the reactive distillation columns. In the framework

both simulation modes, steady-state and dynamic, are considered and the

described

by

In

is

a

equilibrium and non equilibrium-based models.

process

(or

liquid

between

transfer

and

non equilibrium) model, mass

rates

rate-based

based

Maxwell-Stefan

the

equaon

vapour phase are considered explicitly,

tions. Equilibrium is attained at the phase interface in the non-equilibrium

from

it

A

to

the

to

go

one model

switching policy makes possible

model.

free

by

following

Gibbs

knowledge

based

the

the

gained,

energy as

on

other,

has

helped

determining

in

Tray

function

the

time.

switch

efficiency

also

of

a

between the non-equilibrium and equilibrium models, and has been studied

for various systems.

The existence of multiple steady state has been verified through simulation

diagrams

Bifurcation

hybrid

the

the

also

confirmed

existence of

model.

with

in

the

simulations.

output multiplicity obtained

Analysis of process controllability at the design stage has been shown to proIn

for

thesis

improving

the

operation.

controllability

process

vide guidance

first

tofor

the

studied

are

presented

as

a

step

systems

reactive

measures

wards control structure selection.

design

for

the

A method

of reactive separation columns at miniobtaining

(investment

and

and

which

will

operating

costs)

total

cost

annualised

mum

is

in

the

be able to maintain stable operation

also

presence of variability

presented.

Acknowledgements

I would like to thank my supervisors David Bogle, Rafiqul Gani and Stratos

Pistikopoulos. Their continuous support and guidance has led to the production of this work. It has been a pleasure to work next to them and I also

thank them for the opportunity of this joint research.

The many technical discussions at ICI, especially with Tom Malik, are also

greatly appreciated.

Financial support from the Centre for Process Systems Engineering, CAPECResearch Center and ICI is gratefully acknowledged.

Special thanks go to Carlos, Nicolas, Sonia, Alejandro and Marta for introducing me to the challenge of research.

It has been a pleasure to work amongst different groups, in Lyngby and here

in London. The time would not have been memorable and enjoyable withlike

have

had

I

I

to

the

thank particularly

would

out

nice people

around.

to: Eduardo, with whom I have worked and discussed a lot about reactive

distillation, and with whom I shared the difficult times far away from home;

Cecilia, my office-mate from the old times, it have been a pleasure to work

discussed

Celeste,

her;

I

I

to

piles of work and with whom

with whom

next

keep my Spanish 'up-to-date'; my part-time flat-mates in the 'London time',

the 'adventure guys', Soraya and Geoff; Vik, my desk neighbour at IRC, who

day.

has

to

the

working

start

a smile ready

always

My dearest friends Marianne, Ari, Stefan and Angelika will always be refor

in

friendship

for

their

their

encouragement good

and

sincere

membered

bad

times.

and

I would also like to thank my family for their love and everlasting confidence

through the years.

Last but not least, I would like to thank Jes, my lovely husband, without

infallible

in

been.

His

have

trust

this

my

support and

may never

whom all

these

has

years.

over

all

me

motivated

work

2

Contents

Introduction

1.1

Reactive Distillation

12

1.2

Motivation

14

1.2.1

1.3

2

3

12

.......................

Aim

Work

the

of

and

................

Problem

Overview

Definition

....................

15

..............................

Review

Literature

Background:

18

2.1

Reactive and Non-reactive Distillation

2.2

Modelling- Design- Synthesis Issues

3.1

3.2

Equilibrium

2.2.2

Non-equilibrium

Equilibrium

21

..........

................

Non-equilibrium Models

.............

3.2.1 Maxwell-Stefan Equations

3.4

Model Formulation

3.5

Equations

28

33

Models

Model Equations

3.7

................

....................

(rate-based) Models

18

21

Issues

3.3

3.6

in Process Engineering

Models

2.2.1

Modelling

15

.................

................

.....................

Generation of Models

...............

3.6.1 Tray Efficiency

..............

Condensers and Reboilers

............

3

........

........

........

........

........

........

........

........

........

........

35

35

36

39

41

42

59

66

69

3.8

Computational and Numerical Aspects

.............

3.8.1 Specifications for Equilibrium and Non-equilibrium Sim-

71

ulations

3.8.2

..........................

Solution of Model Equations

3.8.3

Initialisation

3.8.4

3.9

71

...............

74

........................

Switching between Models and Monitoring of Phenomena 76

Conclusions

76

............................

4 Validation

4.1

of models

Systems Studied

....................

4.1.1 MTBE: Methyl- Tert- B utyl- Ether

4.1.2

78

......

......

Ethyl Acetate

.................

4.1.3 Depropanizer Column

............

4.2 Initialisation

......................

4.3 Validation of Models

.................

4.3.1 MTBE

.....................

4.3.2 Ethyl Acetate

.................

4.3.3 Depropanizer Column ............

4.4

Bifurcation Analysis

4.4.1

4.5

.................

Applied Bifurcation Analysis

Conclusions

......

......

......

......

......

......

......

......

......

.........

......

......

......................

79

79

86

91

91

94

94

102

106

107

109

114

116

5.3

Models

Hybrid

with

Monitoring of Phenomena through Gibbs Free Energy .....

Tray Efficiency Analysis

.....................

Illustration of Hybrid Modelling Approach ...........

5.4

Conclusions

132

5 Analysis

5.1

5.2

6

71

Controllability

6.1

............................

Issues and Dynamic

Controllability

6.1.1

Issues

Linear Model

.......................

.......................

4

Optimization

117

119

128

133

134

135

6.1.2

6.2

6.1.3

..................

Controllability Tools

6.1.4

Control Configurations

6.1.5

Examples of Application

Dynamic Optimization

6.2.1

6.3

7

Scaling

Optimization

Conclusions

.........

..........

.........

.........

.........

........

.........

.............

problem

.........

.........

.........

...................

General Conclusions

.........

and Future Work

137

139

140

143

150

153

159

160

Nomenclature

163

References

167

A

Properties

179

A. 1 Enthalpy

179

A. 2 Density

....................

..........

....................

..........

A. 3 Viscosity

....................

A. 4 Surface Tension

................

A. 5 Thermal Conductivity

............

A. 6 Binary Diffusion Coefficients

.........

..........

..........

..........

..........

180

181

181

182

184

B Results

B. 1 Simulation Results for MTBE

..................

B. 1.1 Controllability Analysis for the MTBE production

...

B. 2 Esterification of Acetic Acid with Ethanol

...........

184

189

203

219

C Optimization

CA

180

Objective Function and Disturbances

5

..............

219

L0ist of Figures

1.1

Exemplary reactive distillation

2.1

Residue curve map for MTBE. (P=Iatm)(Ung

1995b)

...............................

2.2

3.1

4.1

column

16

.............

Doherty,

and

25

McCabe-Thiele like diagram for MTBE. (Perez Cisneros et al.,

1997a)

...............................

26

Schematic representation of an stage in the column (KrishnaTaylor,

1985)

murty and

.....................

40

Multiple solutions in the MTBE column

96

............

Temperature profiles for low and high conversionin the MTBE

column ...............................

4.3 Equilibrium constant for MTBE synthesis ...........

Colombo

Hoffmann,

Rehfinger

Simulation

4.4

et

and

results with

for

MTBE

DIPPR

the

column .............

al. and

for

ASPEN

PLUS

those

Simulation

4.5

of

results compared with

the MTBE column ........................

4.2

4.6

Simulation results with the equilibrium and non-equilibrium

for

MTBE

the

column ...................

model

for

different

thermodynamic

Simulation

models

4.7

results with

the esterification column .....................

for

data

the

Simulation

4.8

results compared with experimental

esterification column .......................

4.9 Mass Transfer rate for the esterification column ........

literature

Comparison

transfer

results ....

4.10

rate with

of mass

6

97

98

99

101

102

103

104

105

106

4.11 Simulation results with the non-equilibrium

propanizer column ........................

for

dethe

model

108

4.12 Vapour compositions compared with ChemSep simulations

109

..

4.13 Bifurcation diagram for the esterification column varying reflux flow rate

...........................

4.14 Bifurcation diagram for the MTBE column varying reflux flow

111

112

rate

................................

4.15 Bifurcation diagram for the MTBE

boil-up

...............................

5.1

column varying vapour

113

Excess Gibbs energy for the esterification column. Trays I

7................................

and

118

5.2 Excess Gibbs energy for the MTBE column. Trays 4 and 10. . 119

5.3

Vapour compositions for the esterification column

.......

5.4

Efficiency

for

the esterification

calculated

5.5

Efficiency

depropanizer

for

the

calculated

5.6

Vapour composition

5.7

Efficiency

calculated

for the depropanizer

for the depropanizer

column

column

120

121

.......

122

.......

123

column

.......

from

far

column

steady-state

............................

5.8 Efficiency calculated for the depropanizer, compared with those

Ethane

ChemSep:

of

.......................

5.9 Efficiency calculated for the depropanizer, compared with those

Propane

ChemSep:

of

.......................

Propane

depropanizer

for

the

Efficiency

5.10 Point

column:

....

fixed

5.11 Liquid composition profile with equilibrium model with

model ..............

efficiency and non-equilibrium

fixed

5.12 Vapour composition profile with equilibrium model with

model .............

.

efficiency and non-equilibrium

5.13 Hybrid

the

to

esterification

model applied

column

......

.

124

125

126

127

129

130

131

(10%

linear

from

the

model

Response

non-linear

and

6.1

obtained

138

step change)............................

in

increase

10%

MTBE

reboiler

6.2 High conversion of

as result of

145

heat duty

..............................

7

6.3

Low conversion of MTBE as a result of 15% decreasein reboiler heat duty

146

...........................

6.4 Lower purity of MTBE as a result of adding extra reactive stages147

6.5 Reactive distillation column for the design study

154

........

6.6 Top and bottom compositions of ethyl acetate. Results from

the simulated nominal casewith disturbance

156

...........

6.7

6.8

Ethyl acetate composition. Results from the dynamic optimization ...............................

Controlled variable: Reboiler Heat Duty(* 10'(MJlh))

Re.

from

dynamic

the

sults

optimization ...............

157

158

B. 1 Decreasing 10% methanol feed flow-rate

........

.....

B. 2 Increasing 10% methanol feed flow-rate

.........

.....

B. 3 Increasing 10% isobutene feed composition

.......

.....

B. 4 Decreasing 15% isobutene feed composition

......

.....

B. 5 Decreasing 10% isobutene feed composition

......

.....

B. 6 Poles and Zeroesfor Case I (MTBE)

.........

.....

B. 7 RGA element (1,1) as a function of the frequency for Case I

(MTBE)

..............................

B. 8 Singular values for Case I(MTBE)

...............

B. 9 Step responsefor Case I (MTBE). (10% step size)

.......

B. 10 Poles and Zeroes for Case 2 (MTBE)

..............

B. 11 RGA element (1,1) as a function of the frequency for Case 2

MTBE

of

.............................

185

B. 12 Step response for Case 2 (MTBE). (10% step size) .......

B. 13 Poles and Zeroes for Case 3 (MTBE)

..............

198

B. 14 RGA element (1, I) as a function of the frequency for Case 3

(MTBE)

..............................

B. 15 Singular values for Case 3 (MTBE) ...............

(10%

(MTBE).

for

Case

3

Step

B. 16

step size) .......

response

B. 17 Poles and Zeroes for Case 1 (Esterification) ...........

8

185

187

187

188

190

191

192

193

195

196

199

200

201

202

204

B. 18 RGA element (1, I) as a function of the frequency for Case I

(Esterification)

....

205

......................

B. 19 Step response for Case I (Esterification).

(10% step size)

...

207

B. 20 Poles and zeroes for Case 2 (Esterification)

...........

B. 21 RGA element (1, I) as a function of the frequency for Case 2

(Esterification)

....

......................

B. 22 Singular values for Case 2 (Esterification)

............

B. 23 Step responses for Case 2 (Esterification). (10% step size)

.

B. 24 Poles and zeros for Case 3 (Esterification)

..........

B. 25 RGA element (1, I) as a function of the frequency for Case 3

(Esterification)

.....................

....

B. 26 Singular values for Case 3 (Esterification)

...........

B. 27 Step responses for Case 3 (Esterification). (10% step size)

.

9

209

210

212

.

.

.

.

.

213

215

216

217

218

List

2.1

2.2

3.1

Tables

of

Thermodynamic equilibrium approaches for the

simulation of

distillation

reactive

columns ...................

Design approaches for reactive distillation columns

......

Thermodynamic

3.2

3.3

List of equations per stage in the non-equilibrium

3.4

Various forms of non-equilibrium

3.5

List of variables per stage in the equilibrium

3.6

List of equations per stage in the equilibrium

3.7

Various forms of equilibrium

3.8

Computational

equations

4.1

4.2

models

model ....

model

...

model

model

61

62

63

............

models ...............

times for solution of different

24

47

models

.....................

List of variables per stage in the non-equilibrium

22

......

......

63

64

65

sets of model

75

.............................

Range of Variables

........................

MTBE Column Design. Data taken from Jacobs and Krishna

(1993) except for the tray design which has been calculated in

this work

..............................

82

83

Modelling alternatives for MTBE system

............

4.4 Ethyl Acetate Column Design. Data from Suzuki et al. (1971)

in

been

has

design

this

the

tray

work.

calculated

which

except

86

Modelling alternatives for Esterification system

........

4.6 Depropanizer Column Details. Data taken from Taylor and

Krishna (1993)

...........................

90

4.3

4.5

10

88

92

4.7

Selected set of numerical statistics for the three distillation

systems ..............................

6.1

Basic control configurations

6.2

Ratio control configurations

6.3

Measured variables for the controllability study on MTBE production

...............................

Controllability indices for the MTBE production

........

Measured variables for the controllability study on ethyl acetate production

.........................

6.4

6.5

6.6

Controllability

6.7

Optimization

6.8

Optimization

94

141

...................

142

...................

indices for the ethyl acetate production

148

148

149

149

....

details

.......................

results: nominal and optimal values ......

11

155

.

159

Chapter

1

Introduction

1.1

Reactive

Distillation

Reactive distillation is a hybrid unit which comprises distillation and reaction in a single unit operation.

Recently reactive distillation has become a strong interest in chemical endistillation

has

been

the

gineering research, although

concept of reactive

known for a long time. In the 1920's the technique was applied to esterification processes using homogeneous catalysts (Backhaus, 1921). In 1971,

Sennewald described a development employing solid heterogeneous catalysts.

The most important benefit of reactive distillation lies in the economics: a

in

capital cost, energy saving, raw materials and solvent reducreduction

tion. By carrying out distillation and chemical reaction in the same unit,

is

the

associated pumps, piping and

with

along

one process step eliminated,

(the

This

instrumentation.

area or

gives safer environmental performance

just

hazards

is

one continuous

significantly reduced with

scale of risk and

(the

heat

better

of reaction

energy management

operating unit) as well as

but

increase

better

transfer,

boil-up

no

phase

vapour-liquid

and

more

creates

in temperature; therefore, no cooling is required).

Particularly good candidates for reactive distillation are processesin which

by:

the chemical reactions are characterised

12

unfavourable reaction equffibrium: all chemical reactions have an equilibrium

reaction. There are chemical reactions for which, at operating temperature,

the mixture at chemical reaction equilibrium conditions still contains considerable concentration of reactants. Even if one of the reactants is present

in a high concentration the reaction will not proceed. Such reactions are

For these chemical reactions the connormally so-called equilibrium-limited.

be

increased

by

from

the reacting

version can

continuous removal of products

mixture.

high heat of reaction: some chemical reactions have large heat of reaction

(exothermic or endothermic). If these reactions occur in reactors they will

In

distilthe

temperature

the

change

and modify

reaction progress. reactive

lation the heat of reaction will not modify the temperature, the phases will

boiling

heat

the

the

point, and

of reaction will not affect the reacremain at

tion equilibrium. In the case of exothermic reactions, the heat of reaction is

directly used for the distillation process.

large excess of reactants required: reactive distillation is also potentially attractive whenever a liquid phase reaction must be carried out with a large

large

In

this

situation, conventional processes need

excess of one reactant.

distillation

however,

(for

the

could

reactive

excess of reactant);

rec y7cle cost

be carried out closer to stoichiometric conditions minimising the recycle cost.

Reactive distillation prevents side reactions and overcomes limitations due

to chemical equilibrium by its natural separation.

limitations

imdistillation

the

can overcome

azeotropic conditions: reactive

by

azeotropic mixtures: simultaneous chemical and phase equilibrium

posed

has the most beneficial effect of reacting away some of the azeotropes and

behaviour.

the

thereby, simplifying

phase

is

distillation

to

a

applicable

especially

reactive

catalysts:

systems with solid

The

important

that

points

catalysts.

solid

employ

certain class of reactions

disthe

the

catalyst at

activity of

that characterise the catalyst systems are

the

the

reactants and products.

tillation conditions and

relative volatility of

The balance between these two characteristics makes some chemical systems

for

technique.

this

perfect candidates

highly

is

it

is

distillation

that

disadvantage

system

The main

of reactive

for

be

its

to

each

process.

separately

assessed

needs

suitability

and

specific

13

Reactive distillation has a strong dependency on the properties of the chemical system that is dealt with. The poor knowledge of the chemical reactions

features, (catalyst, kinetics, hold-ups) and distillation (vapour-liquid equilibria, thermodynamics, plate and/or packing behaviour) together with their

in

distillation

difficult

to simcombination

a reactive

unit, makes such a unit

ulate and operate.

Reactive distillation appears to be an interesting process unit. Models capable of dealing with different processes are still not available. Although fully

limits

for

the

equilibrium considerations may give

reaction and separation,

distillation

(real

reactive

columns will not operate at equilibrium

operations

are not at equilibrium).

1.2

Motivation

Aim

Work

the

and

of

The motivation of this study has been the interactions between reaction and

interest

in

for

Increased

the

that

units

a reactive column offers.

separation

the application to fine chemicals and pharmaceuticals, as well as in the comhas

been

incentive

industry

this

of

work.

an

also

modity chemical

The main objective of the present work has been to generate appropriate

tools to derive an optimal design of reactive distillation operations.

The objective has been tackled by:

distillation

for

developing

reactive

rigorous models

e

systems;

best

the

to

dynamic

formulating

choose

optimisation problem able

a

e

for

task;

(from

the

given

a

possible alternatives)

all

structure

the

openusing

studied,

system

on

analysis

controllability

0 performing

loop controllability indicators; and finally,

(dynamic

optimization)

0 applying optimal control

distillation

columns.

active

14

for the design of re-

Problem

Definition

Consider the reactive distillation

column in Fig. 1.1 where a mixture is

to be separated into two product streams. The

mixture of A and B will

react to C and D. Operational constraints, such as product specifications,

be

in

must

met

spite of the presenceof variability in the feed streams over

time (disturbances in composition of A or B). The

is

to design

objective

the reactive column at minimum total annual cost with the

goal of ensuring

feasible operation for all product specifications

over time.

In order to undertake such problem, a number issues

be

to

of

need

addressed:

Rigorous

(equilibrium

based)

models

for

and

non-equilibrium

accounting

highly non-ideal mixtures need to be implemented. Simulation

and sensitivity analysis should be performed to study whether operability problems,

such as multiplicity, can occur.

Optimisation techniques to choose the best design for a

given task should

be considered. An objective function including economics of the

process and

factors,

other

such as operability indicators, should be included.

1.3

Overview

This thesis is structured as follows,

Chapter I gives the introduction, motivation and the aim of this work.

Chapter 2 briefly shows the most relevant literature in the area of reactive

distillation. The Chapter is divided into two Sections. The first one addressesthe literature in terms of equilibrium models presented. The second

the

area of non-equilibrium models.

one addresses

Chapter 3 gives a full description of the hybrid model presented and used in

this work. A brief discussionhighlighting the equilibrium and non-equilibrium

The

is

Maxwell-Stefan

A

detailed

equations are also given.

models presented.

Section with the set of equations describing the hybrid model is presented.

Generation of models from the hybrid framework as well as computational

Chapter.

the

aspects

are given at end of

and numerical

15

aillate

c

B -->C+D

Ittom

D

Figure 1.1: Exemplary reactive distillation

16

column

Chapter 4 presents the validation of models. First the systems studied in this

thesis are presented, then the model validation for each system is studied.

Finally a continuation method integrated into the hybrid approach is also

bifurcation

the

presented showing

analysis.

Chapter 5 gives the application of hybrid models. Whenever computational

time is to be saved, then combination of non-equilibrium and equilibrium

be

from

determine

To

it

is

to

models should

used.

when

possible

switch

one

free

Gibbs

to

tray

tray

energy over the

another,

efficiencies and excess

model

highlighted.

be

Hybrid

time

modelling results are

should

analysed.

simulation

Chapter 6 gives the controllability issues and dynamic optimization.

theory description precedes the results.

A brief

Chapter 7, as last Chapter of this thesis, presents the conclusions and future

directions from this work, as well as highlighting the main contributions of

this thesis.

17

Chapter

2

Background:

Literature

Review

"The idea of evolution is closely associated with an increase of organisation

the

to

giving rise

creation of more and more complex structures"

(Glansdorf and Prigogine, 1971).

2.1

Reactive and Non-reactive

Process Engineering

Distillation

in

Different pieces of equipment configure a chemical plant. Some of these

be

distillation

likely

Distillation

is

to

columns.

one of the

equipment are

The

'stage',

in

concept of

chemical engineering.

which

oldest unit operations

describes distillation columns has been known for over a hundred years. The

description of a distillation column continues by characterising defined flows

flows

heat

These

leaving

they

of

mass

or

and

consist

stage.

any

entering and

feed

flows

draw

flow

be

the

through

the

column,

or any

vapour/liquid

can

flows. Distillation displays different types of multiple phenomena such as

heat

flow,

heat

transfer,

phase equilibrium, mixing, material and

mass and

'equilibrium

distillation

is

in

kind

the

The

column

a

of stage

simplest

etc.

has

the

implies

This

the

that

of

any

component

chemical potential

stage'.

liquid

in

the

phase.

vapour and

same value

big

have

that

It is well-known

advantage: a consisone

equilibrium models

big

is

in

that

the

However

their

solution

tent model.

cases:

most

weakness

is potentially very far from the real process.

18

This weakness has been overcome by chemical engineers with the help of

the efficiency concept. The Murphree efficiency is commonly used for tray

because

its

implementation

in equilibrium models is straight

columns mainly

forward. When using this efficiency we assumethat the vapour composition

obtained with the equilibrium model is not the real composition but that the

fraction

is

tray

real

composition

a

of the tray composition. For binary sephave

the

two

the same value, the concept works

arations, where

efficiencies

but

failing

it

quite well,

starts

when multicomponent mixtures are considered

(Wesselingh, 1997). Efficiencies are often assumed'constant' throughout the

Practical

helps

deciding

'value'

in

be

column.

experience

which

should

used

for a particular example.

What is to be done if we do not want to use the efficiency concept? Recently,

Wesselingh (1997) suggested the 'dream of a chemical engineer', saying: 'subdivide each piece of equipment into zillions of little elements dx. dy. dz, each of

in

Using

the

the

then the

phases

equipment'.

which will contain part of one of

difference form of Navier-Stokes equations for the hydraulics, the MaxwellStefan equation to calculate the diffusion flows, and Fourier equations to

describe the energy transfer, together with the corresponding balances and

boundary conditions we should be able to solve the 'real problem'. However,

be

term

it

the

to

on

a

short

solution

obtain

possible

won't

unfortunately

basis: it is a dream.

Between this 'dream of engineers' and the usual equilibrium approach, there

is the non-equilibrium model, which in these days takes into account the

it

that

the

the

important

vapour

assumes

column:

characteristics of

more

Equilibthermodynamic

liquid

in

the

equilibrium.

column are not at

and

The

interface.

the

is

equations of equilibrium

phase

only assumed at

rium

Well

for

forces

driving

transfer.

the

the

to

mixed

then

mass

obtain

used

are

description

the

liquid and vapour phases are mainly considered and

of the

included.

is

between

heat

the

transfer

phases

mass and

in

1970s

the

been

the

have

area of

Significant advances

early

made since

Simulations

distillation

state

of

steady

columns.

of

modelling and simulation

including

shutdown

and

start-up

operations

state

unsteady

operations and

operations are quite common nowadays.

different

for

the

the

simulation problems

At the end of

models used

century,

including

issues,

the

to

simulation

and

modelling

complex

address

attempt

19

those related to separation of azeotropic mixtures and simultaneous separation and reaction: reactive distillation.

The main technical advantage of reactive distillation is the continuous removal of reaction products. However, as reactive distillation still involves

longer lead time for research, which kind of models should be applied to the

Can

distillation

be

unit?

a

model

extended to consider the simultaneous

physical and chemical phenomena? Would one need a 'special' model to describe the proposed problem?.

Reactive distillation

be

(simultaunits can

modelled as an equilibrium system

neous physical and chemical equilibrium); at physical equilibrium with kineticall y7controlled reaction; or as a non-equilibrium system (separation through

kinetically

transfer

mass/heat

plus

controlled reaction); or even maybe as a

combination of these models which could also be an interesting way of looking at the process.

The selection of the appropriate model type, form and simulation mode

(steady state or dynamic) for a particular simulation problem depends on

the problem being solved. The separation task will provide details for the

being

the

the

separated,

required

simulation

mode,

existence of reacmixture

tions and/or azeotropes and many more. The choice between non-equilibrium

(or rate-based) and equilibrium models, although obvious, is not always followed. That is, since any distillation operation will not attain true equilibis

the

the

most appropriate selection.

always

non-equilibrium model

rium,

The equilibrium-based model, however, predominates in terms of application

A

here

is

implement

the

it

is

to

to

arises

again:

solve.

question

and

easier

as

the

to

all

phenomena occurcapture

non-equilibrium model always needed

in

the

reactive column?

ring

Ideally, what is needed is a computer aided system with a general distillation

be

forms

that

from

the

generated

so

can

necessary model

which all

model

for

If,

be

a particular simulation problem, more

answered.

our question can

becomes

the

type

than one

computer aided system should

necessary,

of model

hybrid

through

the

the

be able to generate

use of a

problem specific model

hybrid

The

generating

consists

of

approach

modelling

approach.

modelling

for

defining

their

hybrid models and

example, modelling of

solution method,

the

trays

distillation

or

use

and

non-reactive

with

reactive

column

single

a

trays

model

equilibrium-based

and

model

on

some

non-equilibrium-based

of

20

on the remaining trays. Also, for any design/ analysis/ control problem, the

hybrid modelling approach will

allow switching between steady-state and

dynamic modes and different forms

of models. This will make the transfer of

data (information) from one simulation

sub-problem to another transparent

'noise-free'.

Smooth

transfer of data also means better initialisation

and

and

consequently, a more robust and efficient solution technique. In this thesis

has

been

an attempt

made to present such a model.

2.2

Modelling-Design-

Synthesis

Issues

This section has been divided into two parts, one is

related to equilibrium models presented in the open literature. The other one treats nonequilibrium-based models.

2.2.1

Equilibrium

Models

The literature review on distillation has been extensively addressed in the

Several

books

past.

offer the possibility of understanding, as well as showing how to model, design and control a distillation unit. Examples are,

King (1980), Kister (1990,1992), Luyben (1974), Skogestad and Postleth(1996),

few.

For

have

focused

to

this

here

waite

name a

reason we

on the

description of the researchover the years of only reactive distillation columns.

In recent years a large number of computational algorithms have been rebalance

to

the

solve

ported

mass and energy

equations together with the

data

describing

distillation

The

the

phase equilibrium

reactive

problem.

unknown variables determined by solving these equations are mole fractions

both

flow-rates

temperatures,

rate of reaction and

of

phases, stage

of each

for

The

is

the

equilibrium model

standard model

simulating reactive

phase.

distillation.

key

The

in

is

these

that the

assumption

models

or non-reactive

leaving

liquid

in

a

non-reactive

stage

reactive or

are

equilibrium

vapour and

(liquid

both

temperatures

the

vapour)

on

stage are assumed equal.

and

and

Table 2.1 summarises some of the simulation approaches using a thermody(many

for

distillation

reactive

more are presented

namic equilibrium model

in the literature, but all of them offer more or less the same characteristics).

Most of the research has focused upon steady-state solution of the model

The

for

earliest algorithms

steady state simulation of staged reequations.

21

Authors

Suzuki et al.

(1971)

Saito et al.

(1971)

Komatsu and Holland

(1980)

Perez Cisneros et al.

(1996)

Table 2.1: Thermodynamic

distillation

columns

active

Equilibrium- Simulation Features

Steady-state model.

Kinetically controlled reaction.

Margules's modified equation for

the thermodynamic model

Experimental results from a pilot

plant.

Steady-state model.

Instantaneous reaction.

Model specific for the esterification

example treated.

Steady-state model.

Kinetically controlled reactions.

Homotopy- Continuation method of

solution.

Dynamic model.

Kinetically controlled reactions.

General model including nondistillation.

reactive

for

the simulation of reequilibrium approaches

(1971)

(general

Suzuki

by

distillation

et al.

columns were reported

alactive

(1971)

Saito

Newton

methods);

et al.

gorithm employing quasi-linearisation

(rather specialised, involves instantaneous reaction equilibrium, etc.); and

Nelson (1971) (employing modified Newton-Raphson).

During the years several other algorithms with different methods of solu(1980),

Holland

HolKomatsu

for

been

have

tion

and

example,

studied,

land (1981), including quasi-Newton methods combined with the 0-method

(1977)

(1976),

Komatsu

Hlavacek

Jelinek

used relaxation

and

of convergence.

(1991)

(1988)

Bondy

Seader

Chang

(i.

false

transient);

and

and

e.

methods

homotopy-continuation

The

homotopy-continuation

methods.

worked on

fail.

Through

Newton

is

the

to

methods

problem when

solve

a way

method

into

is

transformed

the

one

problem

can

solve

a

problem

pararnetrisation

in

that

by

occur

naturally

or

parameters

parameters

additional

using

either

(parametric

the model

continuation).

belong

to tearing methods and take a two tier approach

Inside-out algorithms

22

in which the physical properties are approximated by

in

the

simple models

loop

outer

while the model equations are solved at the inner loop (simultaby

Newton's

neously

methods). These kinds of methods are the subject of

industrial research, as is shown by Venkataraman et al. (1990).

Dynamic equilibrium models for distillation have been presented by Gani

(1986,1989),

Cameron et al.(1986) and Ruiz et al.(1988). Their adet al.

vanced equilibrium stage model including rigorous hydraulics has been applied not only to continuous columns but to shut-down/start-up for columns

Recently,

the model has been adapted to handle reactive distillation

as well.

(Pilavachi et al., 1997).

To the best of our knowledge there are few papers in the literature, apart

from our own work (Perez-Cisneros et al., 1996,1997a; and Pilavachi et al.

1997), that addressed dynamic simulation of reactive distillation columns:

Ruiz et al. (1996) and Schrans et al. (1996), Scenna et al. (1998).

From the 1980's the interest focused mainly on the design aspects of reactive

distillation columns. Several research groups have been dedicated extensively

for many years to this area and to the understanding of the interactions between separation and reactions.

The design of reactive columns has followed different kinds of approaches:

transformed

variable approach;

based

balance

approach;

- element

(including

design

through

techniques

synthesis).

optimization

Table 2.2 highlights some of the main features obtained for the design of

distillation

columns.

reactive

In the two first approaches, full equilibrium is considered. Doherty and coGani

been

the

transformed

have

variable approach, while

working on

workers

based

Both

balance

focused

have

the

approach.

element

on

and co-workers

less

for

in

terms

containing

systems

visualisation

of

excellent

are

methods

than four components.

for

design

been

has

the

Optimization

as well as synthesis of

applied

also

kind

This

distillation

a

superstrucutilises

of

approach

processes.

reactive

23

Authors

Design Features

Barbosa and Doherty (1987,1988a, Developed tools for analysis of reb), Ung and Doherty (1995a,b,c)

active mixtures with a single equilibrium reaction. Later extended to

multiple equilibrium reactions with

inclusion of inerts.

Perez Cisneros et al.(1996,1997a,b) Development of tools based on the

balance

for

element

approach

multiple equilibrium reactions.

Ciric and Gu (1994)

MINLP for the optimal reactive col(minimising

umn

annualised cost)

for multicomponent mixtures and

kinetically controlled reaction.

(MINLP)

Synthesis framework

Ismail (1998)

for multi-component and multi(kinetically

controlled)

reactions

Hold-ups and catalyst loads are

for.

explicitly accounted

Table 2.2: Design approaches for reactive distillation

columns

feed

is

to

ture which

streams, multisystems containing multiple

applicable

kinetic

component mixtures and multiple reactions which are considered as

Pistikopoulos

instead

based

and

of equilibrium reactions.

expressions,

rate

for

developing

been

have

a superstructure approach

working on

co-workers

design and synthesis of reactive and non-reactive distillation columns.

Barbosa and Doherty (1987) introduced a new set of composition variables,

idenis

to

the

which

a

problem

reaction

considering

problem

which reduces

dimensionality

the

the

thus

phase

of

tical to one without reaction

reducing

for

systems.

multicomponent

problem

and chemical equilibria

diadeveloped

Different tools they have

are: computation of reactive phase

for

azeotropes,

derivation

reactive

conditions

general

and

of conditions

grams,

b;

Doherty,

1987,1988a,

(Barbosa

and

maps

curve

of

residue

computation

the

As

the

bc).

1995a,

of

Doherty,

visualisation

Ung and

an example of

for

the

in

transformed

system

reactive

the

variables

curves

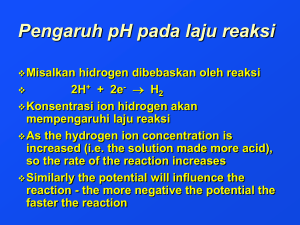

residue

method,

is

inert

presented

component

with n-butane as

isobutene-methanol-MTBE

in Fig. 2.1.

24

Image removed due to third party copyright

Figure 2.1: Residue curve map for MTBE.

1995b)

(P=latm)(Ung

Doherty,

and

The element balance based approach was developed originally by Michelsen

(1995) and extended by Perez-Cisneros et al.(1997b). Again, in this apin

dimensionality

is

The

the

the

reduction

problem used.

of

proach,

approach

is based on the fact that the number of 'elements' needed to represent a reless

is

in

than

the

number of components present the reactive

active systems

These

'chemical

but

they

elements

are

not

necessarily

elements',

mixture.

be

the

chemical

single

element,

a

part

of

molecule

or

a

or

even

comcan

The

for

itself.

this

to

the

solution

method

approach

reduces

wellponent

known physical equilibrium problem, which obviously gives a great advantage. Tools developed for this approach for the design of reactive distillation

include:

diagrams,

for

reactive phase

general conditions

element recolumns

McCabe-Thiele-like

(Perez-Cisneros

diagrams

1996,

et al.,

active azeotropes,

25

Image removed due to third party copyright

Figure 2.2: McCabe-Thiele like diagram for MTBE. (Perez Cisneros et al.,

1997a)

1997a, b, Pilavachi et al., 1997). As an example of the methodology and

diagram

like

is

Fig.

McCabe-Thiele

for

in

2.2

the

the

shown

visualisation,

MTBE reactive system.

A design methodology is also described by Pilavachi et al.(1997) which inthree

steps:

cludes

(i) validation of models (including as well selection of thermodynamic models);

(ii) identification of variables sensitive to design, and;

(iii) analysis of these effects on the design and operation of reactive units.

26

Ciric and Gu (1994) developed a synthesis schemefor reactive distillation

fairly

processescombining a

complex equilibrium model with rate-based kiThe

netic expressions.

resulting optimization model is a MINLP. The total

is

function.

The solution of such problems

the

annualised cost

objective

yields the optimal number of trays, reflux ratio, heat exchanger duties and

liquid hold-ups throughout the column.

Recently, Ismail (1998) developed a mass/heat transfer framework within a

superstructure environment which can handle reactive separation systems.

The approach is based on fundamental mass and heat transfer principles.

Units of process alternatives are not prepostulated, but instead these are

generated according to the synthesis objectives.

Summary

Since the 1950s new algorithms are presented frequently for solving the equilibrium stage model equations for distillation columns. However this is not

has

been

Still,

done

implication

in

that

the

everything

area.

many sepaan

Some

hard

them

to

remain.

of

yet

or

are

are not solved

solve

ration problems

(Taylor and Lucia, 1995). The same problems apply to reactive distillation

few

due

fact

in

the

that

to

the

research

area started a

years

more strongly

later (1970s) with equilibrium staged models.

The equilibrium model has been used for reactive distillation without considlack

knowledge

because

the

the

tray

of

about

of

efficiencies, mainly

eration of

data

Experimental

these

are practically not available.

efficiencies.

values of

For the design of reactive distillation columns, the variable transformation

limited

based

balance

to

the

simultaneous

are

approaches

element

as well as

limits

This,

the

the

of

of course gives

chemical and physical equilibrium.

Variable

this

but

condition.

units will rarely work at

possible separation,

From

0-1.

the

'compositions'

the

leads

to

eletransformation

range

outside

is

to

to

there

based

compositions.

component

go

no

way

compositions

ment

both

For

These element compositions are not always useful.

approaches,

four

for

difficult

than

become

techniques

commore

of

mixtures

visualisation

(or

elements).

ponents

in

Using the superstructure approach results

a probably more realistic and

is

The

distillation

this

design

accuracy

of

price

columns.

of

reactive

accurate

27

for

by computationally demanding models. At present, limited

paid

steady

state equilibrium models or limited mass/heat transfer models have been

used. This highlights the need for a complex model, able to capture all the

phenomena present in the reactive distillation process for the superstructure

formulation.

2.2.2

Non-equilibrium

(rate-based)

Models

Rate-based models appear to be the most appropriate for reactive distillation

due

to the fact that the a priori computation of stage efsystems, primarily

ficiency is avoided (Taylor and Krishna, 1993; Sivasubramanian and Boston,

1990).

In general, a non-equilibrium model includes separate mass and energy balfor

each phase, equilibrium relations and mass and energy transfer

ances

The

for

linked

by

models.

conservation equations

each phase are

material

balances around the interface, since there is no accumulation at the interface

(the mass lost by the vapour phase is gained by the liquid phase). Equilibinterface.

to

the

rium relations are used

relate compositions at either side of

Mass and energy are transferred across the interface at rates that depend on

the extent to which the phases are not in equilibrium with each other. These

from

in

transfer

correlations

mass

multicomponent sysrates are calculated

tems (Taylor and Krishna, 1993). Note that equilibrium stage models are a

limiting case of the non-equilibrium model. If non-equilibrium simulations

larger

done

interfacial

100

times

than

they

areas

about

considering

really

are

(Powers

be

the

then

matched

et al.,

results of an equilibrium model can

are,

1988).

Physical reality is more accurately captured through the non-equilibrium

between

Interactions

reaction and separation are considered explicmodel.

itly through mass and heat balances around the vapour and liquid phases,

in

the

case of reactive systems.

respectively,

The non-equilibrium models that have been developed for distillation prointo

interesting

insights

the

have

effect of multicomponent mass

given

cesses

transfer.

The model developed by Krishnamurthy and Taylor (1985) has been the

28

'base' for any other further development of non-equilibrium models. The

model, with or without modifications has been applied for many researchers

to the study of non-reactive columns. Recently reactive columns have also

been studied with the 'base-model'.

Well-known applications of reactive distillation include heterogeneous reactive distillation processes in packed columns such as et herificat ions; processes

involving highly non-ideal mixtures such as esterifications or etherifications;

high

in

least

and systems with a

reaction equilibrium constant

which at

one of

the component concentration is low such as esterification of acetic acid with

(1994)

Taylor

ethanol.

et al.

pointed out that rate-based models are particfor

modelling packed columns; strongly non-ideal systems; sysularly useful

tems with trace components; columns that exhibit minima or change rapidly;

A

or processes where efficiencies are unknown.

non-equilibrium model seems

the way of modelling a reactive distillation column, instead of the well-know

equilibrium

model.

Another key reason for using a non-equilibrium model instead of an equilibfor

is

that

typically

no good predicsystems

reactive

separation

rium model

tive methods exist nor is experimental data available for stage efficiencies.

Kooijman and Taylor (1995) have developed a rate-based model for the sim'second

The

dynamic

tray

generation' of

columns.

operations of

ulation of

behaviour

dynamic

it

is

the

of

called, considers

non-equilibrium model, as

distillation

drop

the

throughout

the column as well as pressure

column.

Gorak and co-workers have done extensive research in the area of packed

for

their

including

with

comparison

obtaining experimental results

columns,

devices

the

Packed

more comand

contact

columns are continuous

models.

differential

is

transfer-based

technique

model using mulmass

used a

mon

Gorak,

(Gorak,

Kenig

1995).

1987,

theory

transfer

and

ticomponent mass

for

is

from

the

developments

this

One of the latest

rate-based model

group

for

the

batch

experiments

scale

as

pilot

well

as

columns,

packed

reactive

(Kreul

1998,1999).

al.,

et

methanol

with

acid

of

acetic

esterification

case of

the

described

(1997)

have

Pelkonen

of

Also,

experimental validation

et al.

distillation;

for

dynamic

multicomponent

of

simulation

approach

rate-based

imple(1999)

in

the

Kenig

simultaneous

which

a

work

presented

al.

et

and,

for

reactive

approach

and

non-equilibrium

model

equilibrium

of

mentation

has

been

distillation simulation

addressed.

29

Although rate-based models for distillation are now

(see

Seader,

quite common

1989; and Taylor and Lucia, 1995, for an interesting review) such

for

models

distillation

in

development

the

The

first

reactive

in

are still

the

stage.

work

field of rate-based model, to the best of our knowledge,

Sawistowski

was

et

(1979)

al.

who modelled a packed reactive distillation column for the esterification of acetic acid with methanol to methyl-acetate. An effective diffusivity

type was used for the mass transfer model along with irreversible kinetics for

the reaction which can lead to a high percentage of error (40%) in the prediction of the mass transfer rates. This may be due to the fact that there is

lack

a

of theoretical and physical understanding with this effective diffusivity

(Taylor

Krishna,

1993).

method

and

Zheng et al.(1992) and Sundmacher (1995) presented rate-based models for

the production of MTBE on a heterogeneouscatalyst, which usesthe MaxwellStefan equations for the description of the mass transfer. The heterogeneous

is

being

(mass

transfer effects to

reaction considered as

pseudo-homogeneous

from

lumped

the

together into a catalyst efficiency term).

and

catalyst are

Just recently more research in the area started to be published (Higler et

b;

Kreul

1997,1998,1999a,

1998,1999)

al.,

et al.,

although of a commercial

(ASPEN

Guide,

PLUS

User

1997) of a generalised steady state rateversion

based model (RATEFRAC) capable of handling reactive systems has been

for

in

industry.

The

has

been

ten

the

almost

years

available

model which

described by Sivasubramanian and Boston (1990) is a steady-state model

based on that of Krishnamurthy and Taylor (1985) for non-reactive columns.

It considers resistance to mass transfer in both phases, but the examples

literature

in

in

to

the

are simplified

resistance

only one phase

open

shown

(liquid or vapour).

Recently, Higler et al.(1997,1998,1999 a,b) presented a non-equilibrium

(applied

distillation

homogeneous

for

the

to

esterification of

reactive

model

by

transfer

simultaneous

accompanied

acetic acid with ethanol), where mass

Maxwell-Stefan

described

is

the

continuity equations.

using

chemical reaction

In their model no expression for calculating the interfacial area is presented

infor

both

These

fixed

is

Lewis

the

phases.

assumptions are

number

and

(liquid

Only

first

in

by

the

the

troduced

phase)

paper.

one phase

authors

is

to

the

the

transfer

case

resistance considered when applying

model

mass

both,

liquid

disregarded,

is

in

Heat

transfer

that

temperatures

so

and

study.

30

vapour phases, are the same.

Summary

Reactive distillation involves multicomponent mixtures, but other distillation

involve

Systems

binary

multicomponent

also

mixtures.

containing

mixtures

(which are practically not used) are more simple to model: efficiencies, for exfor

both

ample, are equal

components. In multicomponent systems, however,

diffusive interaction, reverse diffusion, osmotic diffusion and mass transfer

barriers are of importance. It is clear that efficiencies can be different for

(Taylor

in

Krishna,

Simulation

1993).

tray

each

each component and

and

importance

then

together with a good unand optimization are

of particular

derstanding of the process. It has never been presented when and for which

(such

the

to

the

assumed simplifications

model

as equirange of operation

librium, constant flows, etc. ) are valid. Lack of accurate simulators restricts

for

distillaimprovement

direction,

in

this

reactive

specially

even more any

tion.

Non-equilibrium models will continue to develop. Indeed they will be used

for

the

case of multicomponent non-ideal mixtures, reactive sepamassively

(Taylor

Lucia,

low-efficiency

1995).

and

processes

ration and

The main needs for using a non-equilibrium model at the moment are:

kinetics;

- reaction

for

transport

better

pure

properties

and

physical

of

predicting

methods

dynamic

(specially

for

for

simulation);

mixtures

components as well as

large

for

that

a

range

over

cover

energy

coefficients

and

mass

correlations

the operating conditions;

the

hydraulic

units.

of

performance

be

it

been

though

have

Very sophisticated models

poswill

presented, even

it

is

However,

further.

them

such

whether

clear

not

to

still

extend

sible

in

insights

the

be

developments can

problem.

solving

warranted or give more

Most of the non-equilibrium models can, at this stage, accurately represent

here

that

is

this

it

data.

However,

to

remarking

without

industrial

say

unfair

data

that

find

the

hard

data

that

is

to

of

nature

often

and

very

experimental

is unknown. There comes a point where the value of complex models must

Can

it

be

be compared with what can

obtained using simplified models.

0.05%

large

to

in

tedious

time

get

a

models

to

complex

solving

expend

pay

31

increase in accuracy? Probably the accuracy of the thermodynamic or transdata

lower

is

than that.

port property

Model integration, where equilibrium and non-equilibrium models can be acfor

distillation

be

the

cessed

same

unit; where steady-state simulation can

dynamic

be

to

the

equilibrium model can

applied

switched

simulation; where

for any stage of a column (if thermodynamic equilibrium is attained) while

the rest of the unit will continue in the simulation as a non-equilibrium model.

Model integration also where different types of models, simplified or rigorous

directly.

both

be

In

types

that

of model, equilibrium and

sense,

accessed

can

Still

have

been

integrated.

time

today

computational

never

non-equilibrium,

is an important issue, and the non-equilibrium model requires longer time

to achieve the solution. A model combining both types of model is called

for

To

be

'hybrid

to

a specific column configuration

account

able

model'.

a

dynamic

the

of

model equations

optimization

and control structure as well as

be

these

tasks

be

in

that

implemented

performed.

can

all

a way such

should

In this thesis an attempt to develop a complete hybrid model is presented

In

both

between

together with a way of switching

addition, steadymodels.

be

Dynamic

dynamic

optimization can also

modes are considered.

state and

performed.

32

Chapter

Modelling

3

Issues

Within the chemical industries distillation is the most used unit. Its inherent

(multicomponent

dynamics)

it

difficult

nature

mixtures and complex

make

to model and to simulate.

In this Chapter a detailed hybrid model (dynamic which can be also switched

to steady-state) including both equilibrium and non-equilibrium approaches

for continuous distillation and reactive distillation is presented. In the case

Murphree

the

to

the

model,

efficiency

values

are

added

equilibrium

of

equilibrium stage to account for deviation from ideality while for the rate-based

(or non-equilibrium) model mass transfer is considered explicitly using the

Maxwell-Stefan equations together with binary mass transfer correlations.

The hybrid model approach is presented addressing important characteristics

behaviour

dynamic

the

of multicomprocesses such as steady-state and

of

implemented

framework

The

using

model equations are

ponent mixtures.

the ICAS-integrated simulator (Gani et al., 1997) and gPROMS(PSE Ltd.,

1997).

Validation of the model is highlighted by matching the results with experi(whenever

literature

in

data

the

possible) or against

open

available

mental

for

The

several reactive and nonresults achieved

other simulation results.

is

the

that

the

to

accurately

propredict

show

model

able

reactive systems

Through

time.

comparison of equilibrium and non-equilibrium

cessesover

for

distillation

is

it

to

that

the

show

reactive

possible

simulation results

largest differences occur when the rate of reaction becomes important. The

33

in

bulk

liquid

between

the

transfer

the

the

the phases,

reaction

affects

mass

of

thus moving the equilibrium.

Rate-based models lack appropriate experimental correlations, especially for

heat

(as

transfer;

mass and

equilibrium-based model are not accurate

previKrishna,

hence,

Taylor

both

1993),

ously reported,

and

a model combining

forward

fast

towards

approaches gives a step

and relatively accurate simulation.

In Sections 3.1 and 3.2 some details of equilibrium and non-equilibrium moddescription

Maxwell-Stefan

together

the

with a

of

equations.

els are given,

From Section 3.3 the model developed in this work is described. Assumptions

(with the corresponding justifications) are highlighted.

34

3.1

Equilibrium

Models

Since the 1950's modelling of distillation has been based on the equilibrium

feature

key

is

leaving

The

liquid

that

the stage

vapour and

streams

stage.

are at equilibrium with each other.

Three different types of equilibria are presented in the equilibrium term: material equilibrium (there is no net change of material between the phases),

(there

thermal

are no velocity gradients), and

equimechanical equilibrium

librium (there is no difference between the phase temperatures) (Bird et al.,

1960). Since no distillation unit operates at equilibrium, efficiencies are used

to account for departures from equilibrium. For binary systems, efficiencies

between

This

bounded

0

1.

for

both

they

and

components and

are

are equal

does not hold for multicomponent mixtures, mainly because of the diffusional

interactions, as defined by Toor(1964). The diffusional interactions include:

its

diffusing

diffusion(when

is

own concentraagainst

a component

reverse

has

diffuses

it

if

diffusion(when

tion gradient), osmotic

no

even

a component

barrier(when

transfer

the

a component

mass

concentration gradient), and

does not diffuse despite its concentration gradient).

3.2

Non-equilibrium

Models

When deriving a non-equilibrium model, one of the following theories should

be applied at the interface (if fluid-dynamic equations are not considered),

be

forty

(there

that

theories

than

for example

applied),

can

are more

theory,

two-film

the

model

9

boundary-layer

theory,

the

*

theory,

the

or

penetration

9

theory.

film

penetration

9

because

is

(Whitman,

1923)

experimostly used

The two-film model theory

is

This

theory

is

theory.

to

this

data

reported

also

adapted

available

mental

factors

such as chemical reactions causes

to give accurate results, even when

The

(Taylor

though,

Krishna,

1993).

theory,

transfer

in

the

and

mass

changes

includes various simplifications.

35

3.2.1

Maxwell-Stefan