Uploaded by

common.user103423

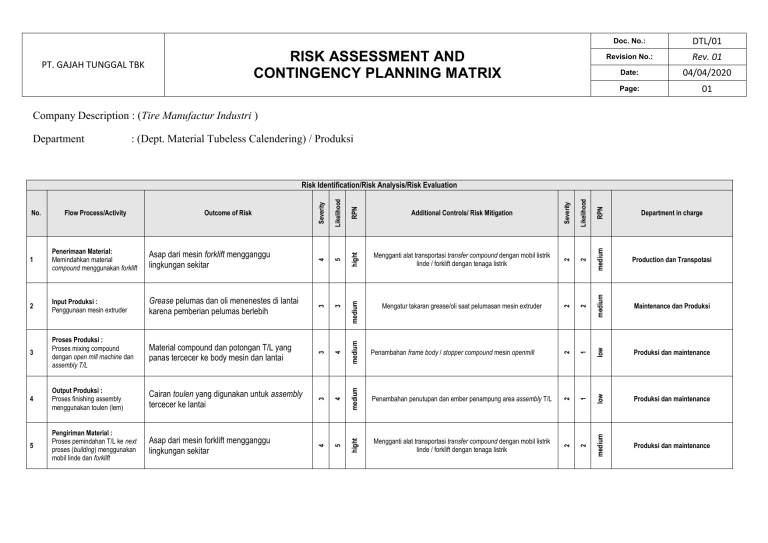

Risk Assessment and Contingency Planning Matrix for Tire Manufacturing

advertisement

RISK ASSESSMENT AND CONTINGENCY PLANNING MATRIX PT. GAJAH TUNGGAL TBK Doc. No.: DTL/01 Revision No.: Rev. 01 Date: 04/04/2020 Page: 01 Company Description : (Tire Manufactur Industri ) Department : (Dept. Material Tubeless Calendering) / Produksi Likelihood RPN Department in charge 2 medium Production dan Transpotasi 2 medium Maintenance dan Produksi 1 low Produksi dan maintenance 1 low Produksi dan maintenance 2 medium Severity 2 2 2 Mengganti alat transportasi transfer compound dengan mobil listrik linde / forklift dengan tenaga listrik 2 Likelihood Penambahan penutupan dan ember penampung area assembly T/L 2 Asap dari mesin forklift mengganggu lingkungan sekitar RPN Pengiriman Material : Proses pemindahan T/L ke next proses (building) menggunakan mobil linde dan forklift hight 5 medium Cairan toulen yang digunakan untuk assembly tercecer ke lantai medium Output Produksi : Proses finishing assembly menggunakan toulen (lem) Penambahan frame body / stopper compound mesin openmill medium 4 Mengatur takaran grease/oli saat pelumasan mesin extruder hight Material compound dan potongan T/L yang panas tercecer ke body mesin dan lantai 5 3 Proses Produksi : Proses mixing compound dengan open mill machine dan assembly T/L 3 Grease pelumas dan oli menenestes di lantai karena pemberian pelumas berlebih Mengganti alat transportasi transfer compound dengan mobil listrik linde / forklift dengan tenaga listrik 4 Input Produksi : Penggunaan mesin extruder Additional Controls/ Risk Mitigation 4 2 5 Asap dari mesin forklift mengganggu lingkungan sekitar 4 Penerimaan Material: Memindahkan material compound menggunakan forklift 3 1 3 Outcome of Risk 3 Flow Process/Activity 4 No. Severity Risk Identification/Risk Analysis/Risk Evaluation Produksi dan maintenance Risk Level Risk Acceptability Recommended Actions DTL/01 Doc. No.: Revision No.: Rev. 01 No Additional risk control measures may be needed. RISK ASSESSMENT AND 04/04/2020 Acceptable CONTINGENCY Frequent review and monitoring of MATRIX hazards are required to ensure thatDate: the risk levels. PLANNING Risk Page: assigned is accurate and does not increase over time. 01 A careful evaluation of the hazards should be carried out to ensure that the risk level is Severity Table reduced to as low as reasonably practicable (ALARP) within a defined time period. Medium Interim risk control measures, such as administrative Tolerable Le Severity Description controls or PPE, may be Likelihood Risk Table implemented while longer vel term measures are being established. No impact to the control and implementation of the QMS, and Negligible Management attention 1is required. Level Likelihood Description operational activities Rare Not expected to occur but still possible 1 High risk level must be2reduced to at least Medium Risk before commences. Minor changes on daily workwork during daily meetings (i.e. Minor Remote Not likely to occur under normal 2 There should not be any interim risk control measures. Risk control measures should increasing and decreasing of manpower, work scope, location circumstances High etc.). Minimal impact not be overly dependent on PPE or appliances. Not acceptable Occasional Possible or known to occur 3Risk Manpower issue (i.e. medical leave, home leave, on overseas 3 Moderate Frequent Common occurrence 4 If practicable, the hazard should be eliminated before commences. assignment etc.).work Moderate impact but can be dealt with Almost Certain Continual or repeating experience review is required before work commences. 5 Management Major change involving changes to client requirements and 4 Major specifications which affects the Project. Late releasing of Level Likelihood Descriptions Design & Development drawings to proceed with operational 1 Rare Not expected to occur but still possible. activities. Affects project schedule and quality of product 2 Remote Not likely to occur under normal5circumstances. Catastrophic Major impacts which includes process non-conformance in 3 Occasional Possible or known to occur. audits, product non-conformances, shortages of raw materials to complete the job, late schedule of delivery of raw materials, 4 Frequent Common occurrence. Design & Development drawings with incomplete information 5 Almost Certain Continual or repeating experience. for fabrication and servicing. Customer Dissatisfaction and Qualitative Risk Analysis Matrix PT. GAJAH LowTUNGGAL TBK loss of future businesses and profits Likelihood Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) Medium Medium Medium Medium High Medium High High High High Moderate (3) Low Medium Medium Medium High Minor (2) Low Medium Medium Medium Medium Negligible (1) Low Low Low Medium Medium Severity Catastrophic (5) Major (4)