Uploaded by

common.user22628

Drum-Buffer-Rope & Kansei Engineering for Bioproduction Systems

advertisement

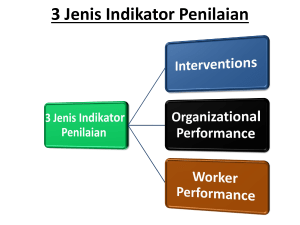

Combining Drum-Buffer-Rope Algorithm and Kansei Engineering to Control Capacity Constrained Worker in a Bioproduction System Mirwan Ushada*. Guntarti T. Mulyati*. Adi D. Guritno*. Haruhiko Murase** *Universitas Gadjah Mada, Faculty of Agricultural Technology, Department of Agroindustrial Technology Jl. Flora No.1, Bulaksumur ZIP 55281 Indonesia (Tel/Fax: +62-274-551219; e-mail: [email protected]; [email protected]; [email protected]). ** Osaka Prefecture University, Graduate School of Engineering, Department of Mechanical Engineering 1-1 Gakuen-cho, Naka-ku, Sakai-shi, Osaka ZIP 599-8531, Japan (e-mail: [email protected])} Abstract: Worker capacity is influenced by various factors of standard time, physical, mood and environment. The Capacity Constrained Worker (CCW) can be described as a worker capacity is close or equal with incoming material so that the fluctuation of incoming material flows possible to shift the CCW into a bottleneck condition of process. Recognizing CCW and bottleneck is essential to maintain the planned product flow in each work station. The objective of the research is to identify and control CCW and bottleneck. The case study of this research is in half-fermented `Tempe` industry. CCW and bottleneck were identified using 4 parameters of standard time, profile of mood status, heart rate and environmental condition. The research results indicated that the CCW was identified on worker of peeling station while bottleneck was identified on the worker of threshing station. The arrival rate of each station inside the Bioproduction system was balanced using the lowest service rate. A buffer time is derived by deviation between service rate of worker in CCW and bottleneck and balanced arrival rate using Drum-Buffer-Rope algorithm. Buffer time was added before threshing and peeling station. Keywords: Heart rate, Motion study, Profile of Mood States (POMS), Time study, Working environment. 1. INTRODUCTION In Japan, Bioproduction system is identical with the development of plant factory. It involves technologies such as process control for the plant growth environment, mechanization for material handling, system control for production and computer applications. The advantages of a plant factory include production stabilization, higher production efficiency, and better quality management of products through a shortened growing period, better conditions, lower labor requirements, and easier application of industrial concepts (Murase and Ushada, 2006). the fundamental industry category which contributes to Indonesian economy which involves bioproduction system. There is more than 54.6 million UMKM who use the man power almost 97.2%. The sustainable and productivity of MSMA should be maintained based on the workers capacity (Anonym, 2010). As shown in Fig. 1, the condition of work station for the worker is complex and influenced by many factors. Using the ideas and methods of Theory of Constraints (TOC) (Goldratt, 2010), Bioproduction system is potential to achieve a large reduction of work-in-process and finished-goods inventories, significant improvement in scheduling performance, and substantial earnings increase. Recognizing Capacity Constrained Worker (CCW) and bottleneck is essential to maintain the planned product flow in each work station (Radovilsky, 2008). The CCW can be described as a worker capacity is close or equal with incoming material so that the fluctuation of incoming material flows possible to shift the CCW into a bottleneck condition of process. Production output depends directly on how the system handles CCW and bottleneck. Any disruption in a production flow caused by ineffective usage of a CCW decreases production output. A time buffer is essential for CCW. The main TOC technique for identifying and controlling CCW and bottleneck is referred to as DrumBuffer-Rope (DBR) (Goldrat, 2010). Fig.1 Work station condition in Indonesian MSMA In Indonesia, Bioproduction system is identical with the Micro-Small-Medium Agro-industry (MSMA). MSMA is Kansei Engineering approach is applicable to model the human sensibility factors using comparison between verbal and non verbal responses (Nagamachi, 2002). Ushada et al. (2012) has utilized diagram method of Kansei Engineering flow from the zero-level concept to extract the Kansei words. The others potential method to apply Kansei words is using Profile of Mood States (POMS). It measures the affective mood state fluctuation in a wide variety of populations. The POMS identifies and assesses transient and fluctuating affective mood states of human (McNair et al., 1992). In this research we formulate the CCW as follow: CCW = f {C, VR, NVR, WE} C = Work response capacity (kg/minute) VR = Verbal response (Mood) NVR = Non-Verbal response (Heart rate) WR = Working Environment (1) Nowadays, various control techniques was developed to improve productivity in Bioproduction system. The physical constraints associated with resources involved in the bioproduction process, such as materials, workers, and equipment. Ushada et al. (2006) has applied the grey level co-occurences texture analysis to control the surface temperature of biomaterial. Ushada and Murase (2009) has developed an intelligent watchdog model to support the equipment for the quality control system. In this research we want to combine DBR algorithm and Kansei Engineering to control CCW and bottleneck in Bioproduction system The goal of the research is to improve the worker productivity in bioproduction system. The specific objective is: 1) To identify the CCW and bottleneck using the work capacity, POMS, heart rate and working environment; 2) To control the CCW and bottleneck by combining DBR algorithm and Kansei Engineering. 2. CASE STUDY AND METHODS 2.1 Case Study of `Tempe` Industry The case study of the research is in Industry of `Tempe` `Muchlar`, Bantul, Yogyakarta Special Province. `Tempe` is made from cooked and slightly fermented soybeans and formed into a patty, similar to a very firm veggie burger. This industry produced half fermented `Tempe` as shown in Fig.2. The industry supplies the product to other division in Sleman region to be a final `Tempe` product. 2.2 Motion and Time Study Motion and time study is an effective method to measure the leanness of a production system (Meyers and Stewart, 2002). It is applicable to measure the time buffer of CCW. When an operator is observed for a period of time, the number of units produced during this time, along with the performance rating, gives Eq.2: tN t0 PR N (2) = Time worked = Number of units produced = Performance rating tN t0 PR A standard time is derived by adding to normal time for personal needs (such as washroom and coffee breaks), unavoidable work delays (such as equipment breakdown or lack of materials), and worker fatigue (physical or mental). The buffer is indicated in Eq.3: ts t N ( AF t N ) (3) = Time buffer = Allowances Factor ts AF A buffer time is derived by deviation between µ service rate of worker in CCW and bottleneck and b balanced arrival rate using Drum-Buffer-Rope algorithm ts 1 b (4) 2.2 POMS In this research, POMS are proposed to derive AF, we used the POMS to measure six identifiable mood or affective states. Questionnaire result is analyzed using T score or known as Total Mood Disturbance (TMD) in Eq.5: TMD = TA + D + AH + F + C – V- F TA D AH F = Tension-Anxiety V = Depression-Dejection F = Anger-Hostility C = Friendliness (5) = Vigor = Fatigue = Confusion. We proposed the mood efficiency, Em in Eq.6 as follow Em TMDa TMDb Fig. 2 Half fermented `Tempe` TMDa TMDb TMDa = TMD Score when starting the work = TMD Score when finishing the work (6) 2.3. Heart Rate Heart Rate (HR) was selected as physiological criteria because it is simple, reliable, and provides good accuracy on manual measurement (Louhevaara and Kilbom, 2005). HR was measured using finger pulseoxymeter during 6 days of work. These 6 days represents the normal day of working in the bioproduction system. In each day we measured the HR every hours with the periods of 07.00, 08.00, 09.00, 10.00, 11.00 am, 12.00, 13.00 and 14.00 pm. 2.4. Working Environment The treatment of temperature, dew point, wet bulb , mixing ratio and relative humidity was measured using Thermo Recorder (Extech RH520 Data Logger). Light intensity was measured using Lightmeter (LX-101 A, Lutron). The noise was measured. 60 Score 40 10 0 A-H m 2 C D-D POMS No 1 Bottleneck CCW Work Station Threshing Finished Product n Elements 1 2 3 Buffer (Time) 2 Washing 1 2 3 Figure 3 described the Drum-Buffer-Algorithm. A "drum" is a control point in the production system associated with a CCW. The name "drum" is derived from the fact that the CCW will set the timing for the rest of the system. "Rope" is the term used for the communication feedback to the workers before the CCW so that each of them produces only the amount of CCW can complete. 3. RESULTS AND DISCUSSION 3.1 Calibration of POMS The Indonesian version of POMS questionnaire was developed. Therefore the calibration of POMS was required to test the questionnaire. The calibration was pursued in 2 (Two) groups of respondents: 1) 57 students, Department of Agroindustrial Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada as shown in Fig.4; 2) 8 workers MSMA, `GNP Snack` in Muntilan, Magelang, Province of Central Java as shown in Fig. 5. 3 Soaking I 1 4 Boiling I 1 5 Crushing 1 2 6 Peeling 1 2 3 7 Soaking II 1 8 Boiling II 1 9 Fermentation 1 10 Packaging 2 1 2 60 Before treatment After Treatment 50 Score 40 30 20 10 0 C T-A V FR 3.2 Motion Study Motion study was pursued to differentiate the work element for the time study. The work elements for each work station can be described as shown in: Fig. 3 Drum-Buffer-Rope algorithm A-H F Fig. 5 Calibration of POMS in workers of MSMA Drum Information Feedback (Rope) T-A Table 1. Work elements for `Tempe` industry Raw Material Dispatching Point 1 30 20 2.3 Drum-Buffer-Rope Algorithm Raw Material Before lunch time After lunch time 50 D-D POMS F V F-R Fig. 4 Calibration of POMS in respondents of student Description Preparing soybean from the bag Handling soybean to the threshing machine Handling threshed soybean to the washing bath Put the soybean in to the bath Cleaning the soybean Put back the soybean in to the bath Handling soybean to the tube and move to boiling Preparing the boiled soybean to the crushing Handling of the soybean Adding the water to the crusher Handling the soybean to the container Peeling Separate the skin and handling to soaking II Handling the soaked soybean to the container and transfer to boiling II Put to the container and handling to the fermentation Handling the soybean to the plate Fermentation Packaging to the bag Weighing the bag H R (Pu lse / m in u te ) 3.3 Profile of heart rate Profile of heart rate can be described in Fig. 6 90 85 80 75 70 65 WS 1 WS 2 WS 3 WS 4 WS 5 WS 6 WS 7 WS 8 WS 9 WS 10 Worker of each work station Fig. 6. Profile of Heart Rate (HR) for workers in each work station 3.4 Measurement of Constraints Table 1 indicated the measurement results for identifying the CCW and bottleneck. Table 2. Identification of constraint in `Tempe` industry No Work Station Kansei Mood Efficiency Heart Rate (Pulse/min) Standard Time (Kg/min) Environment Temperatur e (0C) Dew Point(0C) Wet Blub (0C) 27.4 7±0. 47 Mixing Ratio (g/kg) 19.80± 0.60 1 Thresing 0.78±0.22 79.69±5.40 0.0085 29.54±1.66 24.70±0.51 2 Washing 0.87±0.08 80.42±5.06 0.068 29.54±1.66 24.70±0.51 27.4 7±0. 47 19.80± 0.60 3 Soaking I 0.79±0.12 79.92±4.55 0.021 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 4 Boiling I 0.94±0.05 80.79±4.83 0.027 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 5 Crushing 0.89±0.08 82.25±3.91 0.059 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 6 Peeling 0.91±0.07 83.56±3.70 0.132 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 7 Soaking II 0.88±0.10 84.98±2.83 0.032 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 8 Boiling II 0.92±0.05 83.94±3.92 0.018 34.37±1.12 26.40±0.66 28.9 1±0. 71 22.11± 1.02 9 Fermentation 0.90±0.11 84.00±2.24 0.10 32.36±0.55 26.23±0.60 29.0 4±0. 69 21.90± 0.82 10 Packaging 0.84±0.22 83.15±3.90 0.06 32.36±0.55 26.23±0.60 29.0 4±0. 69 21.90± 0.82 RH (%) Noise (db) 78. 42 ±4. 77 78. 42 ±4. 77 64. 77 ±3. 55 64. 77 ±3. 55 64. 77 ±3. 55 64. 77 ±3. 55 64. 77 ±3. 55 64. 77 ±3. 55 72. 81 ±1. 62 72. 81 ±1. 62 65.81 ±3.40 Light Intensity (lux) 231.55±6 .05 65.81 ±3.40 231.55±6 .05 85.84 ±1.59 339.65±5 .19 85.84 ±1.59 339.65±5 .19 85.84 ±1.59 339.65±5 .19 85.84 ±1.59 339.65±5 .19 85.84 ±1.59 339.65±5 .19 85.84 ±1.59 339.65±5 .19 73.16 ±1.14 189.38±4 .24 73.16 ±1.14 189.38±4 .24 Buffer Time = 26.6 kg/minute 0.053 minute/kg Threshing Raw Soybean 7.6 kg/minute Half Fermented Soybean 16.9 kg/minute Washing 7.6 kg/minute 7.6 kg/minute 28.4 kg/minute 25.97 kg/minute Packaging Fermentation 7.6 kg/minute 7.6 kg/minute 29.9 kg/minute Boiling I 30 kg/minute Soaking I 7.6 kg/minute 18.2 kg/minute Boiling II 7.6 kg/minute 29.2 kg/minute Crushing 7.6 kg/minute 39.3 kg/minute 20.4 kg/minute Peeling Soaking II 7.6 kg/minute Buffer Time = 0.078 minute/kg 7.6 kg/minute Fig. 7 Proposed Drum-Buffer-Rope algorithm 3.5 Identification of CCW and Bottleneck 3.6 Proposed Drum-Buffer-Rope Algorithm CCW can be described as a worker capacity is close or equal with incoming material so that the fluctuation of incoming material flows possible to shift the CCW into a bottleneck condition of process. Therefore, CCW and bottleneck were identified based on work proportion of each station as shown in Table 3. Based on the comparison of utility and mood efficiency in Table 4, it can be concluded that the bottle neck of `Tempe` industry is work station 1 or threshing station. Worker in threshing station indicated the lowest mood efficiency and the lowest utility. The CCW can be identified in work station of peeling which have the lowest of service rate and the highest utility. This CCW could be potential to be a bottleneck. Table 3. Work proportion of each station Based on identification of CCW and bottleneck, we proposed the Drum-Bufer Rope Algorithm in Fig. 7. The lower service rate of peeling 7.6 kg/minute was set as the arrival rate of the system. Buffer time was added before threshing and peeling station. Buffer time for threshing station was 0.053 minute/kg and 0.078 for minute/kg Work Station Threshing Washing Soaking I Boiling I Crushing Peeling Soaking II Boiling II Fermentation Packaging % Worker 100 100 10 100 100 100 10 50 100 100 % Machine 0 0 90 0 0 0 90 50 0 0 3.7 Analysis of Kansei Engineering Figures 8 and 9 indicated the worker involvement in the work station of threshing and peeling. Fig. 8 Worker involvement in threshing the soybean Table 4. Identification of CCW and bottleneck WS ʎ (K g/min ) µ (Kg/mi n) p, ʎ /µ 1 2 3 4 5 6 7 8 9 10 26.6 16.9 30 29.9 29.2 20.4 39.3 18.2 26 28.4 117.6 14.7 47.6 37 16.9 7.6 31.2 55.5 10 16.6 0.23 1.15 0.63 0.81 1.72 2.70 1.25 0.33 2.60 1,71 Mood Category 0.78±0.22 0.87±0.08 0.79±0.12 0.94±0.05 0.89±0.08 0.91±0.07 0.88±0.10 0.92±0.05 0.90±0.11 0.84±0.22 Bottleneck Normal Normal Normal Normal CCW Normal Normal Normal Normal Fig.9 Crushing and peeling station Figures 10 and 11 indicated profile of heart rate in threshing and peeling station. The research results validated the difference of HR between work start and finish. 90 Work Start Work Finish 85 HR (Pulse/Minute) which have the lowest of service rate and the highest utility. This CCW could be potential as bottle neck. Identification of CCW and bottleneck was confirmed to total of mood disturbance and heart rate of each worker. 80 75 70 65 1 2 3 4 Days of measurement 5 6 Fig.10 Profile of heart rate in threshing station Based on identification of CCW and bottleneck, we proposed the Drum-Bufer Rope Algorithm. Buffer time was added before threshing and peeling. The lower service rate of peeling 7.6 kg/minute was set as the arrival rate of the system. Buffer time was added before threshing and peeling. Buffer time for threshing station was 0.053 minute/kg and 0.078 for minute/kg REFERENCES 90 HR (Pluse/Minute) 85 80 75 70 Work Start Work Finish 65 1 2 3 4 Days of measurement 5 6 Fig.11 Profile of heart rate in peeling station Figures 12 and 13 indicated the profile of TMD between work start and finish in threshing and peeling station. The results indicated that worker of peeling station has more consistent patterns between work start and finish than the threshing station. These results confirmed the worker in peeling station as CCW and the worker in threshing as the bottleneck. TMD 12 8 4 Work Start Work Finish 0 1 2 3 4 Days of measurement 5 6 Fig.12 Profile of TMD in threshing station TMD 12 8 4 Work Start Work Finish 0 1 2 3 4 Days of measurement 5 6 Fig.13 Profile of TMD in peeling station 4. CONCLUSSION CCW and bottleneck were identified based on work proportion of each station. Based on the comparison of utility and mood efficiency, it can be concluded that the bottle neck of `Tempe` industry is threshing station. Worker in threshing station indicated the lowest mood efficiency and the lowest utility. The CCW can be identified in work station of peeling Anonym. (2010). Strategic plan of indonesian cooperatives and small-medium enterprises (In Indonesian) 20102014. Indonesian Ministry of Cooperatives and SmallMedium Enterprises Goldratt, E. M. (2010). Theory of constraints handbook. Edited by James F. Cox III and John G. Schleier, Jr. McGrawHill Louhevaara, Veikko and Kilbom, Asa. (2005). Dynamic work assessment .In : John R. Wilson and Nigel Corlett, editors. Evaluation of Human Work, 3rd edition. Boca Raton : CRC Press. p. 429-451. McNair, D. M., Lorr, M., Droppleman, L. F. (1992). Manual for the profile of mood states (Rev. ed.) San Diego, CA: Educational and Industrial Testing Service Meyers, F. E and Stewart, J. R. (2002). Motion and time study for lean manufacturing. Prentice Hall Murase, H. and Ushada, M. (2006). Machine vision applications for micro-precision agriculture. Environment Control in Biology. 44(3): 199-206. Nagamachi, M. (2002). Kansei engineering as a powerful consumer-oriented technology development. Applied Ergonomics. 33: 289-294. Radovilsky, Z. D. (1998). A quantitative approach to estimate the size of the time buffer in the theory of constraint. International Journal of Production Economics, 55(1998) 113-119 Ushada, M., Murase, H. and Fukuda, H. (2006). Intelligent texture analysis for surface temperature of cultured sunagoke moss to model its biophysical behaviour. International Federation of Automatic Control (IFAC) Biorobotics III Workshop in Sapporo-Japan, September 9-10, 2006. pp. 106-111. Ushada, M. and Murase, H. (2009). Development of an intelligent watchdog model for quality control of an affective bio-greening material. International Federation of Automatic Control (IFAC) Biorobotics IV Workshop in Illinois, U.S.A. Paper No. 806 Ushada, M., Wicaksono, A. and Murase, H. (2012). Design of moss greening material for merapi disaster prone area using kansei engineering. Engineering in Agriculture, Environment and Food. 5(4): 140-145