2.4. Penapisan

termal Beberapa metode termal untuk penapisan cocrystal telah diadaptasi dari penapisan

polimorf. Dua metode yang paling umum untuk penyaringan termal dari potensi kristal adalah

melalui pengamatan selama pencairan biner oleh HSM dan dengan mempelajari perilaku fase

dua komponen menggunakan DSC. Dengan metode ini, campuran fisik dari dua komponen

pembentuk kokristal potensial ditempatkan di dalam DSC, di mana mereka dipanaskan di luar

titik eutektik mereka. If cocrystallization is possible then an endothermic peak associated with

the eutectic melting will be observed. This will be immediately followed by an exothermic peak

indicating that full or partial cocrystallization has taken place, between the two components.

Another endothermic point will then be observed which should correspond with the cocrystals

melting point. In contrast, if the cocrystallization is not possible between the two components,

then an endothermic peak indicating the eutectic melting is observed which may be

accompanied by further peaks indicating the melt or degradation points of the individual

compounds [54,55]. This technique was first demonstrated by Lu et al. where DSC was used

to screen twenty possible cocrystal forming systems. Sixteen cocrystals were formed, including

nine previously undiscovered, demonstrating the DSCs potential for cocrystal screening [56].

This method of experimental screening is popular as it does not require the time-consuming

work of solubility determination and is considered green technology due to the absent of

organic solvents [15].

More recently, Shayanfar and Jouyban expanded upon Lu et al. work, assessing the feasibility

of the thermal screening via the DSC approach to screen for cocrystals of ketoconazole. Here,

binary mixtures of ketoconazole and either nicotinamide or 4-amino benzoic acid coformers

were prepared and heated in the DSC to confirm cocrystal formation [57]. Using the rules

outlined by Lu et al., (ie the presence of two endothermic events for the eutectic and melting

point and one exothermic event immediately following the eutectic melt) it was evident that

1

cocrystallization between ketoconazole and 4-amino benzoic acid was possible. A 2:1 mixture

of ketoconazole and 4-amino benzoic acid was then scaled-up via solvent evaporation,

producing the cocrystal in larger quantities. The DSC approach was further explored by Surov

et al. in a study comparing four different cocrystal screening techniques in the development of

bicalutamide cocrystals [58]. Here 1:1 mixtures of bicalutamide and one of eight

pharmaceutically acceptable coformers were prepared and screened using DSC, LAG, slurry

sonication and solution crystallization. Though the study noted the DSC method to be the most

“simple and rapid” method of cocrystal screening, using this approach it was only possible to

identify one potential cocrystal of bicalutamide (1:1 bicalutamide-salicylamide cocrystal). The

resulting thermograms for the bicalutamide-salicylamide cocrystal contained the characteristic

exothermic event indicative of cocrystal formation, confirming that cocrystallization was

possible. For the other systems tested, on such exothermic event was present, however the

presence of only one peak does not imply that no cocrystal is formed as it is possible for the

peaks to overlap, thus the other systems cannot be discounted on the basis of a DSC screen

alone [53, 54]. This was confirmed after all three alternative screening techniques revealed the

successful cocrystallization of a second cocrystal system of bicalutamide and benzamide (1:1),

as well as the bicalutamide-salicylamide cocrystal. It was summarized that DSC screening,

while quick and efficient, cannot be used to screen for cocrystals in isolation.

However, in a comparative study by Manin et al., DSC was found to be the most effective

thermal screening method when combined with HSM [59]. The utilization of HSM is desirable

as it allows the interpretation of any ambiguous results, such as in cases where melting points

may overlap [60]. It is also possible to combine DSC with Fourier-transform infrared

spectroscopy to establish the correlation between the thermal response and the structural

changes of the sample [61]. Mohammad et al. have proposed a combined Hansen solubility

parameter (HSP) and DSC as a useful and effective cocrystal screening approach to short list

2

potential coformers prior to complex laboratory screening experiments [62]. With the HSP

process, the miscibility of cocrystal constituents are predicted using their respective solubility

parameters to assess the likelihood of cocrystal formation. If the solubility difference of an API

and coformer are less than seven, then they are considered miscible and likely to form a

cocrystal. In this study, the miscibility of indomethacin and 33 different coformers were

calculated using HSP. In this instance, all but one of the API-coformer pairs predicted to be

miscible were confirmed to be so, with all miscible API-coformer pairs forming indomethacin

cocrystals.

A technique known as the Kofler contact method utilizes HSM to give a clearer indication of

whether or not cocrystallization has occurred. Here, the cocrystal components which displays

the higher melting point is heated up to that point and melted, before being allowed to solidify.

Meanwhile the cocrystal component with the lower melting point is heated to melting and then

placed in contact with the other solidified component. At this point the component with the

higher melting point is dissolved in the liquid component, creating a mixing zone where the

sample is quenched and recrystallized. This sample is then placed under glass slides alongside

two pure samples of the two cocrystal constituents and heated once again to its melting point

with the two pure samples, under a HSM equipped with a polarizer. Using the HSM equipment,

one can view the newly formed cocrystal alongside the two constituents. The cocrystal will

retain birefringence, allowing it to be distinguishable from the eutectic phase and from the pure

samples, giving a clear indicator of whether cocrystallization was successful [53]. This

technique was successfully demonstrated by Berry et al. who employed the Kofler contact

method to probe the binary phase behaviour of nicotinamide with seven different APIs. Though

three of the systems were failures (owing to incompatible hydrogen bonding and steric

hindrance) three new cocrystal systems were identified (with flurbiprofen, ketoprofen and

salicylic acid) and their structures determined [60].

3

An alternative approach to thermal screening involves measuring the saturation temperatures

of the cocrystal constituents to predict whether crystallization is possible. This technique was

first demonstrated by Ter Horst et al. who used this method to screen for new cocrystal forms

of carbamazepine and cinnamic acid with a variety of coformers, successfully identifying 4

new cocrystals of carbamazepine (with isonicotinamide, nicotinamide, benzamide and

3nitrobenzamide) and two cocrystals of cinnamic acid with (isonicotinamide and

3nitrobenzamide) [63]. The cocrystal is more stable than the two individual components

meaning, that in an appropriate solvent, the cocrystals solubility will be lower than either

component. Therefore, cocrystallization should be achieved once the product of the component

concentrations exceeds a set value at a constant temperature. Using Ter Horst's approach, by

measuring saturation temperature at a composition which correlates to saturation with respect

to both components at a reference temperature, it is possible to asses if cocrystallization has

occurred if the measured saturation temperature is more than 10˚C higher than the reference.

2.5. Slurry screening

Slurry based techniques have been adapted from polymorph screening, and proved an effective

method when screening for cocrystals. In this method, the API will be added to the mixture,

with cocrystallization taking place at the point where the concentration of the constituents is

above the critical activity of the coformer. In the slurry method, the cocrystals constituents are

suspended in a solvent where partial dissolution occurs, resulting in activity values of one for

both components. This means the slurry activity is greater than the critical coformer activity

required for cocrystallization. When allowed sufficient time and mobility, nucleation will

occur, causing the API and coformers to convert to the cocrystal via solution-mediated phase

transformation, until either of the component activities decrease to the critical value [64,65].

4

In the first instance of large scale screening using a slurry based method, Zhang et al. slurried

known stoichiometry of 16 known API-coformer systems for periods varying between twelve

hours to eight days [66]. The stoichiometry tested were either 2:1 or 1:1 of 10 different API

including caffeine, cis-itraconazole, trimethoprim, sulfamethazine, carbamazepine, aspirin,

piroxicam and flurbiprofen were mixed with twelve different coformers including

nicotinamide, saccharin and other common acid based coformers. Different solvents utilized in

the slurry include, acetonitrile, cyclohexane, methylene chloride and n-heptane. In addition to

producing known cocrystals for thirteen of the systems tested, two new solvated structures were

reported for 1:1 trimethoprim-sulfamethoxypyridazine cocrystals, using acetonitrile and

methylene chloride. Furthermore, new unsolvated structures for 2:1 ibuprofen-nicotinamide

and 1:1 aspirin- 4,4′-dipyridyl were reported.

In a more recent study, Bučar et al. screened for new cocrystals of theophylline using

solutionmediated phase transformation using nine different (di)-hydroxybenzoic acids as

coformers as part of an extended study to establish synthon hierarchies in cocrystals with

multiple hydrogenbonding functional groups [67]. The screening revealed eight new cocrystals

of theophylline as well as the formation of a salt. In another instance, new cocrystal structures

were reported for stanolone and mestanolone after extensive screening via slurry crystallization

with eleven different pharmaceutically acceptable coformers. Two new cocrystal forms were

reported; stanolone-L-tartaric acid (1:1) and mestanolone-salicylic acid (1:1) [68]. The method

has also been used to identify nine new cocrystals of caffeine with different carboxylic acid

based coformers [69].

A slightly different approach, first reported by Rodríguez-Hornedo et al. involves using

nonstoichiometric solution compositions to achieve supersaturation of cocrystals in solvents

where the cocrystal components have non-equivalent solubilities. This is known as the reaction

crystallisation approach [65]. If the cocrystal constituents do not have similar solubilities there

5

is a chance that the evaporation of the equimolar solution will result in a single component

crystal as opposed to the cocrystal, due to supersaturation being generated with respect to less

soluble reactant. Using this approach one of the cocrystal formers is added to a saturated

solution of the other component, allowing the solution to become super saturated with respect

to the cocrystal form. Childs et al. expanded upon this work, successfully employing reaction

crystallization by adding carbamazepine to saturated solutions of 18 different coformers in one

of four separate solvents (water, ethanol, acetonitrile or ethyl acetate), leading to the

identification of 27 unique solid forms [70].

2.6. Mechanochemical grinding based screening

The mechanochemical grinding approach to screening for cocrystals is essentially the same as

described for salts. This approach uses kinetic energy to incite cocrystallization by

mechanically grinding the cocrystal components at various speeds usually by either manual

grinding or through a ball milling process. The ball milling technique induces cocrystallization

through particle size reduction via impact with numerus steel balls, when the components are

loaded alongside the steel balls into a rotating chamber. As with salt screening, the process can

be either neat grinding or LAG. This technique provides innate advantages over more

traditional solution based methods of having lower costs and lesser waste than solution based

methods; dissolution of the cocrystal constituents is not required, removing any issues relating

to solubility differences between API and coformer; and there is a reduced chance of the solvent

interacting with the API, disturbing solute-solute interaction (this drawback is removed

completely using neat grinding methods) [71].

In an early example, Friščić et al. [72] demonstrated the effectiveness of mechanochemical

grinding compared to solution methods in screening for ternary cocrystals of caffeine and

succinic acid (1:1). Screening was done by adding a diverse range of 25 potential 'guest'

compounds alongside the caffeine: succinic acid cocrystal and ball milling for 20 minutes and

6

liquid assisted experiments, acetonitrile was also added. This was performed alongside

traditional solution based methods. Out of 25 potential hits, only four cocrystals were found

using the solution based methods compared to the 16 cocrystals found in the neat grinding

studies and 18 in the LAG studies, demonstrating the potential of mechanochemical grinding.

In a more recent study, Heiden et al [73] used both neat grinding and LAG via ball milling to

successfully screen for cocrystals of theophylline-benzoic acid (1:1).

Recently, LAG has proven the more popular method, due to the higher success rate of the

method compare to neat grinding. This was demonstrated by Friščić et al. in a comparative

study of the neat and LAG [74]. Out of four known cocrystal structures tested only one,

theophylline-L-malic cocrystal, was successfully obtained using neat grinding methods while

LAG was able to produce all four targeted structures. Furthermore, the theophylline-L-malic

cocrystals produced via LAG were found to have a greater degree of crystallinity compared to

their neat grinding produced counterparts after x-ray powder diffraction (XRPD) analysis. LAG

has also been shown to be the preferable method when screening for cocrystal hydrates. In one

study, neat grinding was performed with the hydrated and anhydrous forms of theophylline and

caffeine API with citric acid coformers. The same was carried out using a LAG with a water

solvent. Ultimately, hydrated cocrystals were possible between the theophylline and citric acid,

but the same cannot be said of the caffeine, which only provides an anhydrous cocrystals with

citric acid, even when both reactants are crystalline hydrates. Cocrystal hydrates of both API

were achievable via LAG suggesting it is the more efficient method of screening for cocrystal

hydrates [75]. Nevertheless, for extensive screening purposes, both methods of screening

should be employed as some cocrystals forms may be exclusively obtainable through neat

methods. One such case was presented by Imai et al. who reported the synthesis of a bis-βnapthol- benzoquinone (1:1.5), which is not obtainable through solution methods [76].

7

One drawback of this method is that it is time-consuming due to the need to grind coformers

with the drug individually. Yamamoto el al. overcame this issue through development of a

“cocrystal cocktail method” where up to four coformers of similar moieties could be co-ground

with the drug via ball milling [77]. This is a synthon-oriented screening method where multiple

forms of different API-coformer pairs can be identified at once and have their bonding

hierarchy's easily classified. The cocrystal cocktail method was found to reduce the workload

by half. A slightly different approach was employed by Li et al. who combined neat grinding

with conventional solution screening methods for greater screening diversity [78]. In the first

stage of screening, up to 25 coformers were ground alongside glutaric acid API in a ball mill

for 20 minutes. The resulting solids were analysed through DSC and XRPD and any trace

amount of a new peak or diffraction pattern respectively was treated as a 'lead'. These leads

were then followed up in a solvent based screen to assess the developability of the cocrystals.

Using this method five new cocrystals were identified as potential cocrystal candidates for

pharmaceutical development within a significantly smaller timeframe. Another approach,

which combines both neat and liquid assisted grinding, saw carbamazepine co-ground with a

diverse number of coformers via mortar and pestle in the initial stage [79]. If a partial

conversion was observed, then a liquid-assisted method through ball milling was employed.

Here, carbamazepine was co-processed with eight different coformers using eight different

solvents and results were compared to cocrystals produced through solution growth. Results

demonstrated that all cocrystals prepared via solution growth were reproducible through the

more cost-effective, environmentally friendly grinding method. Different stoichiometries,

grinding times and rates are variables that can result in different crystals forms in neat grinding

experiments. With LAG, the variety in solvents can provide great diversity in the crystal forms

produced. In the previously mentioned study it was found that dimethylformamide (DMF) and

dimethylsulfoxide (DMSO) provided greater crystallization space which led to a greater

number of cocrystals [79]. Friščić et al. have concluded that the cocrystal formation in liquid

8

assisted methods is dictated by saturation levels of reactants rather than the type of the process

[80].

2.7 Translational development of pharmaceutical cocrystals

The last two decades research and development on pharmaceutical cocrystals has gained

momentum both in industry and academia leading to enhanced scientific understanding,

expansion in intellectual property landscape and evolution of regulatory guidelines [81,82].

According to Kale et al. selecting appropriate formulation and process design together with

understanding material properties during preformulation stage can mitigate the challenges in

the translational development of pharmaceutical cocrystals [81]. Currently, there are two

cocrystal-based products on the market and more in development (Table 1).

Table 1. Cocrystals in clinical development and market.

Cocrystal

Escitalopram

oxalateoxalic acid

(Lexapro®, Lundbeck)

Sacubitril-disodium

valsartan-water

(ENTRESTOTM,

Novartis)

Indication

Status

Ref.

Cocrystal of a salt which is a

selective serotonin reuptake

inhibitor for the treatment of

depression

Marketed (2009)

[82,83]

Multidrug cocrystal for the

treatment of symptomatic chronic

heart failure and reduced ejection

fraction in adult patients

Marketed (2015)

[81,82]

ErtuglifozinLpyroglutamic acid (1:1) Cocrystal for the prevention of

hyperglycaemia in type-2 diabetes

mellitus

Clinical

trials [81,82]

(Phase III)

Tramadol-celecoxib

(1:1)

Clinical

trials

(Phase II)

Multidrug cocrystal for acute

postoperative pain

9

[84]

TAK-020

Cocrystal developed for the

potential treatment of rheumatoid

arthritis containing a tyrosine

kinase inhibitor

Clinical

trials

(Phase I)

[81]

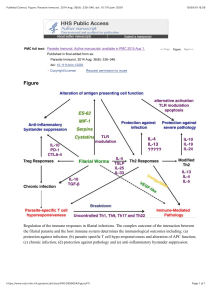

3. Phase diagrams and cocrystallization

Phase diagrams are often considered the method of choice for depicting the thermodynamic

relationships between cocrystals and their individual components (API and coformer). They

can be used as tools towards the more efficient cocrystal search (ie selection of coformer or

solvent) and the prediction of the most suitable preparation method [85]. The phase diagrams

that have been used to depict the phase behaviour of crystallizing systems can be classified in

three types: i) binary phase diagrams, ii) phase solubility diagrams and iii) ternary phase

diagrams.

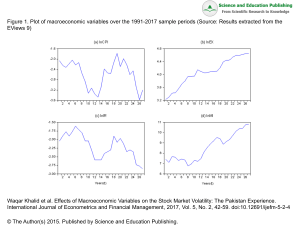

i) Binary phase diagrams (BPDs)

BPDs of an API and a coformer provide information on the thermal stability of the cocrystal

system and on whether the interaction of the two components is strong enough to generate a

thermodynamically stable cocrystal [85]. BPDs are temperature-composition maps which

indicate the equilibrium phases present at a given temperature and composition of API and

coformer (Fig. 2, [86]). Yamashita et al. reported the use of a small-scale and high-throughput

screening method for cocrystals and salts based on BPDs using thermal analysis (ie DSC) alone

or in tandem with X-ray analysis [55]. Despite their usefulness in thermal screening methods,

BPDs do not take into account the presence of the solvent and thus provide little information

regarding solution based crystallization methods.

10

With solution based methods for the preparation of cocrystals the solvent acts as a catalyst

reducing the activation energy barrier of the cocrystallization influencing the kinetics, but not

the thermodynamics, of the transformation [87]. An exception to this is when the solvent

becomes a part of the crystal structure, as seen in the case of solvates. Thus, in solution based

crystallization methods the solvent can be considered as the third component of a ternary

system. Phase solubility diagrams and ternary phase diagrams are the most commonly used

types of graphical representation for a ternary system depicting the solubility and stability of

cocrystals in solution [88–90].

ii) Phase solubility diagrams (PSDs)

PSDs display the solution concentration at equilibrium with the solid phase. Particularly for

cocrystals a PSD shows the solubility curve of the API, coformer and cocrystal phases as a

function of solution concentration of the drug or the coformer expressed as molarity [70].

Therefore, a PSD provides information regarding the stability of different solid phases. A

representative phase solubility diagram for indomethacin-saccharin (1:1) cocrystal in ethyl

acetate is given in Fig. 3.

Fig. 3 shows that the cocrystal solubility decreases non-linearly with increasing coformer

concentration, an analogous effect of the common ions on the solubility of sparingly soluble

salts [88,91]. Moreover, as it is depicted in Fig. 3, the cocrystal exhibits lower solubility

compared to the drug in region IV, indicating that only cocrystals are supersaturated in this

region. Such a knowledge is of paramount importance regarding the scaling-up of the process,

as conditions should be carefully selected to ensure that the crystallisation is conducted in

region IV in order to isolate the pure cocrystal [91].

11

Nehm et al. derived a mathematical model to describe the solubility behaviour of the cocrystals

as a function of cocrystal component concentration in solution by considering the solubility

product (Ksp) and solution complexation constants (K11 and K12) for 1:1 and 1:2 complexes of

cocrystal components formed in solution [88]. After successful application of the model to the

PSD of carbamazepine-nicotinamide (1:1) cocrystals in various solvents, it was concluded that

solubility product and solution complexation constants explain the PSDs of the cocrystals.

Currently, adaptation of the mathematical models has been applied in a few studies and together

with determination of other parameters such as the eutectic constants (Keu) can be useful

diagnostic tools for the screening and scaling-up of pharmaceutical cocrystals [88,91]. In cases

where the solubilities of components (ie drug, coformer) in the solvent/antisolvent mixtures

show strong deviation from ideal-solution, calculations using the perturbed-chain statistical

associating fluid theory (PC-SAFT) show to be in good agreement with experimental data and

thus are useful tools for increasing the efficiency of cocrystal formation by predicting the

solubility of pharmaceutical cocrystals in solvent/antisolvent mixtures [92].

iii) Ternary phase diagrams (TPDs)

Ternary diagrams are commonly used in physical chemistry to represent the phase behaviour

of three-component systems. In most cases, they are equilateral triangles with each side corner

of the triangle corresponding to a pure component. The area of such triangles covers all the

possible combinations of the three components and the sum of the perpendicular distances from

any point to each side of the diagram is a constant equal to the length of any of the sides. In the

field of cocrystals, ternary phase diagrams (TPDs) are mole-based equilateral triangles which

represent the total composition of solid phases and liquid phases at equilibrium [70,89]. TPDs

can be generated by determining the solubility curves of each solid phase (ie drug, coformer

and cocrystal) in the solvent at a specific temperature (Fig. 4).

12

At the eutectic or invariant points (E1 and E2), the solution is saturated with two solid phases

that is the drug and cocrystal, at E1, and coformer and cocrystal, at E2. Based on the Gibbs rule

of phases, there are six zones in a typical TPD, for a system where a drug and coformer are

linked by one stoichiometric relationship (drug + coformer � cocrystal). Straight lines drawn

from the eutectic points to the corresponding pure solid phases (drug, coformer, and the drug

coformer stoichiometric ratio which is 0.50 in the case of a 1:1 cocrystal) together with the

cocrystal solubility curve (E1 to E2) determine the six zones. Zone 1 comprises of

undersaturated solutions of both drug and coformer and is bounded by the solubility curves of

the drug (a to E1), the cocrystal (E1 to E2) and the coformer (E2 to b). The drug is the stable

solid phase in zone 2, the cocrystal in zone 3 and the coformer in zone 4. In zones 5 and 6

(invariant regions), a mixture of cocrystal and drug or cocrystal and coformer exist,

respectively. In each of these zones, the stable solid phases are in equilibrium with a liquid

phase.

Cocrystal systems can be distinguished in congruently and incongruently saturated solutions

[89,90]. Congruently saturating cocrystals are thermodynamically stable when slurried in a

solvent whilst incongruently saturating systems undergo transformation leading to the

formation of less soluble solid form. The congruency or incongruency of a cocrystal system in

a solvent is linked to the relative solubility of the pure cocrystal-components in solvent. More

specifically, when the solubility of the drug and coformer is similar in the solvent, it is likely

that the cocrystal system will be congruently saturating while when the solubilities differ

largely, the cocrystal will be incongruently saturating in the solvent [70]. The TPDs for a

congruently and an incongruently saturating 1:1 cocrystal are shown in Fig. 5.

A congruently saturating cocrystal exhibits a more symmetrical TPD (Fig. 5a) compared to an

incongruently saturating system (Fig. 4b), as in the latter case the zone in which the cocrystal

13

is the stable phase (zone D-C+L) has moved towards the axis of the component with the highest

solubility in the solvent (in this case the coformer, Fig. 5b). For a 1:1 congruently saturating

cocrystal, the solubility curve (E1 to E2) crosses the cocrystal component stoichiometric ratio

line (dashed line), while for an incongruently saturating cocrystal the maximum solubility lies

outside the cocrystal component stoichiometric ratio line.

Construction of TPDs based on experimental solid-liquid equilibrium data in various solvents

and temperatures has been applied in a series of studies to rationally select the method and

conditions of cocrystallization [70,89,93].

Solution crystallization is the most commonly used method for the production of single crystals

and the subsequent crystallographic characterization of cocrystals, but also for scaling-up

purposes. However, the outcomes of solution crystallization are sometimes unpredictable as

there is the risk of crystallizing the single component phases due to the complicated parameters

involved. In contrast to preparation methods in small scale, in which usually binary systems

are used (eg melt crystallization and mechanochemistry), in the solution crystallization the

solubilities of the components in the solvent at different temperatures should be considered

ahead of stoichiometries as different fractions of the cocrystal components can dissolve in the

liquid phase [85]. Therefore, in solution cocrystallization, PSDs and TPDs are important tools

for mapping out the critical region (ie the region where the cocrystal is the only stable solid

phase) thus guiding the selection of crystallization parameters and the starting point for solution

cocrystallization, avoiding the formation of undesired phases. Specifically, data regarding both

the solvent and temperature are important as they have an effect on the phase diagram of a

cocrystal system [89].

Tong et al. generated TPDs of the ethenzamide-saccharin (1:1) cocrystal system in different

solvents (ethanol, methanol and ethyl acetate) where its components were dissolving differently

14

based on the selected solvent. The ehtenzamide-saccharin system dissolved congruently in

ethyl acetate due to similar solubility of ethenzamide and saccharin, but incongruently in

ethanol and methanol due to different solubility, where an excess of ethenzamide is required to

isolate the cocrystal and in turn would increase the cost for the cocrystal production [94]. Based

on the constructed TPDs, ethyl acetate was identified as the solvent of choice for the production

of the ethenzamide-saccharin cocrystals, as the larger and more symmetric region for the

cocrystal was found to be beneficial in cooling and suspension crystallization.

In many cases, a cocrystal hydrate or solvate can be formed during solution crystallization apart

from the cocrystal. Phase diagrams have been used not only to understand the transformation

pathways, but also how to suppress the formation of hydrates or solvates. For example, TPDs

of the theophylline–citric acid anhydrous/hydrated cocrystals have been used for a qualitative

depiction of the stability domains with coformers that modulate the water activity. Water

activities at eutectic points were measured and related to the stability of the anhydrous/hydrated

cocrystal phases in solutions and in vapour phase in a range of relative humidities. It was found

that the presence of coformers that modulate the water activity as trace level impurities with

cocrystal can alter hygroscopic behaviour and stability [95] . For avoiding the problem of

solvation of indomethacin-nicotinamide (1:1) cocrystal in methanol, TPDs in methanol and

methanol/ethyl acetate, at 25 oC and 40 oC, were compared by Sun et al. [96]. The comparison

showed that when increased temperature and/or solvent mixtures were used, the stability region

of indomethacin methanolate was narrowed or even disappeared. By fine-tuning these two

parameters solvate formation could be suppressed, indicating that solubility results and

corresponding phase diagrams can provide the basis as a guide for the manufacturing of

indomethacin-nicotinamide (1:1) cocrystals.

TPDs can also guide the selection of a suitable method for the preparation of a cocrystal by

providing insight on how to access the area of the diagram where the cocrystal is the only

15

thermodynamically stable phase. Chiarella et al. constructed TPDs of trans-cinnamic

acidnicotinamide (1:1) cocrystal at different solvents and temperatures as a basis for

understanding current crystallisation methodologies [89]. In general, for congruently saturating

cocrystal systems in a solvent or solvent mixtures, the cocrystal can be prepared by evaporation

of stoichiometric solutions of the cocrystal components. Instead, for incongruently saturating

system, non-stoichiometric solution concentrations can be used as in the case of reaction

crystallization where the solution becomes supersaturated with respect to the cocrystal as the

drug is dissolved in a saturated solution of the coformer [70]. Interestingly, spray drying and

supercritical fluids drying of stoichiometric incongruently saturating cocrystal systems

generated pure cocrystals suggesting that the formation of cocrystals by this method may be

kinetically controlled or mediated by the glassy state of the materials [97,98]. In Table 1, the

use of PSDs and TPDs for the screening, small-scale preparation and scaling-up of cocrystals

in several studies is reported.

16

Table 2. Some studies based on PSDs and TPDs for the screening, small-scale preparation and

scaling-up of pharmaceutical cocrystals.

Method

Cocrystal system

Features

Ref.

Screening

Carbamazepine ith

Evaporative,

w

carboxylic

reaction and slurry acids

cocrystallization,

LAG

PSDs and TPDs illustrate how [70]

saturation of reactants leads to

supersaturation of the

cocrystal

Spontaneous

cocrystallization

Caffeine-maleic

(1:1) and (2:1)

acid Importance of solvent in the

crystallization

of

stoichiometrically diverse

compounds

[99]

Slurry

cocrystallization

Myricetin cocryst als

A novel strategy for the [61]

preparation of pharmaceutical

cocrystals without knowledge

of the stoichiometric ratio

based on PSDs and TPDs

Wet

milling/grinding

and solution

cocrystallization

Ezetimibe

with

lproline and imidazole

Thermodynamic

phase

diagram

based

high

throughput screening was

performed

using

wet

milling/grinding or solution

crystallization methods.

[100]

TPD and PSD in ethanol as

tools for mapping out the

regions of thermodynamic

stability of the cocrystal and

its components

[101]

Smallscale preparation

of cocrystals

Cooling

Salicylic acid-4,4'cocrystallization

dipyridyl (2:1)

cocrystals

17

Antisolvent

Carbamazepinecocrystallization Shift

of

saccharin (1:1)

carbamazepinesaccharin PSD

by

antisolvent

addition

depicts the dramatic change in

solubility which is the

primary driving force

[102]

towards crystallization by antisolvent

precipitation

Two solution

mixing

Carbamazepinesaccharin

(1:1)

A crystallization method [103]

based on TPDs by mixing

two kinds of different

eutectic solutions

Spray drying

CarbamazepinenicotinamideBased on PSD and TPD,

(1:1)

the under-saturated

region with respect to

cocrystal was identified

and selected as target

region to initiate the

crystallization

experiments

[104]

Scaling-up

Cooling

cocrystallization

CarbamazepinenicotinamideUse of PSD for solvent

(1:1)

selection and optimization

[105]

of solution crystallization

conditions, including the

initial concentration of the

coformer

Cooling

cocrystallization

α-lipoic

(1:1)

acidnicotinamideUse of TPD in developing a [106]

controlled approach to

crystallization using a

continuous

oscillatory

baffled crystallizer

4. Solution based scale-up methods of cocrystals

Various methods have been reported for the production of cocrystals that can be broadly

divided into liquid-based (eg evaporative, cooling, slurry, antisolvent and reaction

18

cocrystallization) and solid-based methods (eg mechanochemistry and twin-screw extrusion).

While mechanochemistry (neat grinding and LAG) is one of the most widely used screening

methods for the formation of cocrystals, its scalability is limited and the intensive energy input

may induce some degree of amorphization and crystal defects, compromising the purity of the

cocrystals formed [107]. Twin-screw extrusion (TSE) employing a combination of controlled

heat and shear deformation, has been successfully used for cocrystal formation [108]. Despite

being an environmentally-friendly method that can be used for the continuous manufacturing

of pharmaceutical cocrystals with high quality, yield and throughput [109], the elevated

temperature required during the TSE process may limit its suitability for thermally unstable

compounds.

Friščić et al. introduced the empirical parameter η (μl mg-1) for the characterization of the liquid

methods, defined as the ratio of the volume of the liquid V (μl) and the sum of the masses of

the API and the coformer (mg) [80]. Based on the value of η, liquid-based methods can be

further subdivided into slurry crystallization (η=2-12 μl mg-1) and solution-based

crystallization (η>12μl mg-1). The main advantage of solution based crystallization methods is

the fact that they enable removal of impurities from the recrystallized product. Also, solution

based crystallization is a prevailing approach for producing cocrystals on a commercial scale

due to the availability of solution-crystallization equipment (eg large stirred tank reactors) in

the pharmaceutical manufacturing plants [110]. In addition, by changing process parameters

(eg solvent, polymer-induced heteronucleation) numerous pathways can be accessed in the

phase solubility diagram indicating that solution based crystallization methods require strict

control but they also offer unique opportunities as each of these pathways may give rise to

unique materials (eg cocrystal polymorphs) [111].

19

Solution based crystallization methods can be employed in various stages of cocrystal

production, from the initial stage of screening using high-throughput methods (in μg) to the

small laboratory scale (in mg) for characterization, the lab-bench pilot scale (in g) and the

scaling-up for commercial production (in kg). During screening, evaporative crystallization is

the most commonly used technique for the production of cocrystals due to its simplicity.

However, techniques such as cooling crystallization and antisolvent crystallization are

preferred for industrial crystallization as they provide more control over crystallization

conditions. In particular, cooling crystallization is considered as the “workhorse” of industrial

crystallization for the past 100 years providing effective purification and control of solid form

and other particle attributes [112]. Thus, a common first step towards the scaling-up of a

crystallization process is to convert from a small-scale evaporation processes into cooling

crystallization [113].

In this section, studies on the scale-up of cocrystals using solution based crystallization methods

will be reviewed with emphasis on the role of phase diagrams as tools towards scalingup.

Special focus will be placed on studies where process analytical technology (PAT) and quality

by design (QbD) principles were implemented for the design, optimization and control of the

crystallization process.

Hickey et al. reported the production of carbamazepine-saccharin (1:1) cocrystals applied on a

30-g batch size using a conventional cooling crystallization process from ethanol/methanol

mixture [114]. The temperature was reduced from 70 oC, at 10 oC increments, to induce

precipitation. Cocrystals started to appear at 50 oC and the temperature was further lowered

down to drive additional precipitation. No seeding was required as the 1:1 cocrystal was found

to be the phase that nucleates from the solution in the supersaturated state. Crystal growth was

found to be a function of cooling rate and incubation time. Cocrystals of plate-like morphology

20

were collected from all the crystallization trials. Regarding crystal size, near-saturated

crystallization resulted in very large crystals while rapid cooling in smaller crystals. A 76%

solid recovery of cocrystals was reported by this method, indicating the potential of cooling

crystallization as a scale-up method.

Sheikh et al. incorporated well-established techniques and procedures used in singlecomponent

crystallization to a complicated cocrystal system of carbamazepine and nicotinamide, which

have significantly different solubilities, and proposed a scalable solution crystallization

methodology enabling manipulation and control of the process leading to desired performance

and product characteristics [105]. The essential elements of the methodology were: i)

development of a solvent selection rationale, ii) identification of domains of thermodynamic

stability in the multi-component solid-liquid phase equilibrium diagram and iii) identification

of the mechanism for inducing nucleation and subsequent control of desaturation kinetics.

Following this methodology, ethanol was the solvent of choice since the solubility of

carbamazepine (API) is approximately half that of the nicotinamide (coformer). This allows a

large driving force for the formation of cocrystal and the widest window for phase-pure

crystallisation of cocrystals. Seeding was used to induce controlled secondary nucleation and

significant de-saturation via crystal growth. A solution of an appropriate concentration was

used for the post-filtration washing of the cocrystals, allowing efficient removal of residual

solution from the wet cake without risking cocrystal stability (ie conversion to the pure

components). Following a rational process design, a robust process at a 1L-scale with yields in

excess of 90% and throughput of 14 L kg-1 was established.

Cocrystals apart from their ability to modify the physicochemical and mechanical properties of

APIs have been used as intermediates in the purification or racemic resolution of APIs [115].

Billot et al. investigated the use of crystallization to purify SAR1, a kinase inhibitor for the

treatment of acute myeloid leukaemia that was found to be resistant to conventional purification

21

techniques (eg chromatorgraphy and impurity adsorption) [116]. Moreover, even though SAR1

exhibits a rich population of solvates, purification via formation of solvates and subsequent

desolvation was found to be inadequate for the crude API feedstock where the presence of

impurities inhibited nucleation and formation of solvates. A two-step crystallization approach

was employed comprising the formation of a cocrystal between the API and a coformer in the

chlorobenzene feedstock followed by the cleavage of the solvate to isolate the API. An initial

five carboxylic acids were selected as potential coformers, based on the synthon approach.

Then, phase diagrams were constructed as indispensable tools facilitating: i) the selection of

the best coformer and ii) the recovery of a purified API within specification for residual solvent.

Specifically, benzoic acid was selected as the best coformer due to the congruent solubility of

the API and this coformer in chlorobenzene. On the contrary, the incongruent solubility of

benzoic acid and the API in isopropanol makes it the most suitable solvent for the cleavage of

the cocrystal, allowing reformation of the pure API by using low solvent volumes. The

crystallization process was initially developed at a laboratory scale and was successfully

transferred to the pilot plant using a filter-drier at a 10-kg scale. At pilot-plant scale, purification

was found to be effective, with the product assay increasing from 65% before crystallization

with benzoic acid to 99% while the purity was retained during the cleavage step. An overall

yield of 54% was reported for the two steps and the final product was found to comply with the

International Conference for Harmonisation (ICH) specification for residual solvents and for

polymorphic form.

5. Process analytical technology for monitoring of solution based cocrystallization

Process analytical technology (PAT) is defined by the US Food and Drug Administration

(FDA) as “a system for the design, analysis and control of manufacturing processes through

timely measurements of critical quality and performance attributes of raw and in-process

22

materials and processes, with the goal of ensuring final product quality” [117]. Implementation

of PAT involves a combination of i) scientifically-based process design and optimization to

identify critical material attributes and critical process parameters, ii) suitable sensor

technologies, iii) chemometrics for the interpretation of multivariate data provided by the

sensor technologies and iv) feedback process control strategies to ensure production of final

products with the desired quality [118]. Application of PAT is the key enabler for the

implementation of QbD concepts in pharmaceutical manufacturing processes such as

crystallization [118].

Regarding monitoring of crystallization processes, sensor technologies should be capable of

measuring key process variables (eg supersaturation) and desired quality attributes (eg size,

shape and polymorphic form) which impact on properties such as solubility, dissolution and

bioavailability but also on downstream operations such as filtration [118]. Sensor technologies

can be differentiated based on whether they provide information related to the liquid or the

solid phase [119]. Monitoring the liquid phase provides information regarding the

supersaturation that can be inferred from the measured solute concentration and the equilibrium

saturation concentration at the same temperature. Real-time sensing techniques that have been

used for the measurement of the solute concentration are attenuated total reflection Fourier

transform

infrared

spectroscopy

(ATR-FTIR),

Raman

spectroscopy,

densitometry,

refractometry and conductivity [120]. Monitoring of the solid phase provides information

regarding crystal size distribution (CSD), shape and polymorphic form. Real-time sensing

techniques that have been used for the determination of these crystal attributes include total

(back) scattering of suspension for particle concentration, forward light scattering for CSD,

focused beam reflectance measurement (FBRM) for chord length distribution and detection of

nucleation events, ultrasound attenuation for CSD, imaging techniques for CSD and shape

23

determination and Raman scattering for quantification of polymorphic forms in suspension

[121]. Below, studies on the use of PAT sensors for the monitoring and control of

crystallization processes are reviewed in detail.

Gagniere et al. selected the cocrystal of carbamazepine-nicotinamide to study its crystallization

kinetics using PAT sensors [122]. Using an in-situ video probe, they investigated the evolution

of solid phases during the cooling crystallization process operated in batch mode. As

carbamazepine-nicotinamide cocrystals (needles) and carbamazepine single crystals (platelets)

exhibited different habits, the video probe was an efficient analysis tool capable to detect and

monitor the evolution of these two solid phases in the slurry. Through this monitoring, it was

demonstrated that the initial conditions were important for the pathway of the crystallization

and relationships between carbamazepine-nicotinamide cocrystals and carbamazepine crystals

were observed, indicating that the nucleation of the cocrystal may be favoured by the presence

of drug crystals. Limitations in the use of the video probe was the qualitative rather than

quantitative nature of information provided and its limited visualization ability when the

cocrystal concentration exceeded 10% weight. In order to complete the study, a quantitative

monitoring was carried out in concentrated slurry (solid content up to 30% weight) using an insitu ATR-FTIR spectroscopy probe which provided estimates of the solute concentrations of

both carbamazepine and nicotinamide at various temperatures [123]. The concentration profiles

allowed the construction of phase diagrams showing the kinetic pathways of the crystallization

process, the determination of the solid form nucleation and the change in the proportion of each

solid phase present in suspension (Fig. 6). Knowledge of the phase diagram at the initial and

final temperatures of the crystallization process allowed the definition of the “safe” operation

region in which crystallization should be conducted to avoid the appearance of solid phases

other than the cocrystal. Moreover, in-situ monitoring of solute concentrations of

carbamazepine and nicotinamide by the ATR-FTIR probe showed that it is possible to induce

24

solution-mediated phase transitions (SMPT) by manipulating the amount of the coformer.

Specifically, addition of nicotinamide in dry form allowed a shift in the phase diagram, leading

to an SMPT from carbamazepine crystals towards cocrystals [124]. In this way, shifting the

overall slurry composition to the desired zone of the phase diagram by adding a certain amount

of one of the components of the cocrystal system can be used as a retreatment process in cases

where the cocrystal phase is polluted by another crystalline phase [125].

In a follow-up study, the cooling crystallization of carbamazepine and nicotinamide was

monitored using two in-situ calibration-free PAT sensors: a FBRM probe sensor for CSD

determination and an in-house-built video probe for shape and CSD determination [126]. The

different habits of the drug and the cocrystal allowed the discrimination between them with

these two sensors. The video probe provided qualitative understanding of the phenomena inside

the crystalliser but it could only be used in low solid concentrations as it becomes blind in high

solid concentrations. On the other hand, the FBRM probe can operate in a wide range of solid

concentrations but its measurements should be analysed with caution since they can lead to

misinterpretation of the phenomena. Thus, it was highlighted that a combination of probes

providing complementary data is essential for the correct interpretation of the data when the

industrial development of a crystallization process is carried out.

In a series of studies, Yu and co-workers studied the cooling crystallization of the polymorphic

caffeine-glutaric acid system in acetonitrile, implementing PAT and QbD methodology. The

phase diagram of caffeine-glutaric acid-acetonitrile was constructed in the temperature range

of 10-35 oC using ATR-FTIR spectroscopy for in-situ measurement of solute concentrations

and by exploiting SMPT for location of eutectic points. Knowledge of the phase diagram

changes with temperature and evaluation of possible kinetic pathways allowed the

establishment of the operating region for the crystallization process [127]. In a second study,

25

the crystallization process was monitored using ATR-FTIR spectroscopy combined with

particle vision measurement (PVM) and supersaturation was calculated as the difference

between the transient concentration of the cocrystal and its solubility [128]. Seeding with the

stable form II was found to avoid nucleation of the metastable form I. In addition, feedback

control of supersaturation was implemented and enabled: i) the maintenance of supersaturation

close to its set point, ii) the elimination of the often problematic polymorphic transformation

process to the metastable form I of cocrystal, and iii) the production of largest particles and

lowest proportion of fines.

In a follow-up study, the design space of the caffeine-glutaric acid crystallization for process

development and scale-up was determined [129]. Polymorphic purity was chosen as a critical

quality attribute and its relationship with five process parameters, namely cooling profile, seed

loading, seeding temperature, seed particle size distribution and starting concentration, was

described by a first-principles process model and an empirical supersaturation threshold. After

the estimation of the model parameters on a bench scale, the supersaturation threshold was

obtained from a few experiments in a 1-L crystalliser. Monte Carlo modelling was employed

to quantify the risks associated with model parameter uncertainty and operational variability.

These risks, while assessed to be significant, could be effectively mitigated by sufficient aging

after seeding. The operating ranges of starting concentration, seeding temperature and seed

loading were modelled and verified experimentally by scaling-up to a 10-L crystalliser.

Caffeine-glutaric acid was also selected as a model system by Sheng et al., who developed a

calibration-free method based on Raman spectroscopy for the on-line identification of

impurities during crystallization [130]. Employing multivariate analysis methods (ie principal

component analysis and discriminant analysis) on the Raman spectra, offered a simple and

industrially amenable approach for identification of impurity in the form of pure component

during crystallization without the need for elaborate calibration.

26

5.1. Current state of scaling up solution based cocrystallization processes

Conventionally, crystallisation processes are operated via batch production. Whilst batch

process may appear simple and allow flexibility to respond to varying customised design

requirements, the underlying science and its control are highly complex resulting in increased

manufacturing costs and batch-to-batch variations in product quality (eg purity, size, shape)

[131]. Continuous crystallisation is gaining momentum in the pharmaceutical industry as the

regulatory authorities support the implementation of continuous manufacturing [132].

Development of continuous production over batch crystallization offers many potential

advantages including better process control, consistent product quality, shorter development

time, reduced costs, more robust scale-up and more efficient use of reagents, solvents and

energy which in turn minimise the production of waste material and reactor downtime for

maintenance and cleaning [131,133].

Zhao et al. discovered a α-lipoic acid-nicotinamide (1:1) cocrystal with enhanced thermal

stability compared with α-lipoic acid, offering significant advantages regarding the production

and storage of this nutritional supplement [106]. In this study, the rapid translation of the

cocrystal from gram to kilogram scale was also reported using a continuous cooling

crystallization process supported by a systematic approach to process design. Specifically, from

the discovery to scaling-up the following consecutive steps were employed: screening of

αlipoic acid with different coformers using liquid-assisted grinding (LAG) and small-scale

solution cocrystallization, generation of single crystal of α-lipoic acid-nicotinamide (1:1)

cocrystal for structure elucidation and characterization, crystallization of this system using

oscillatory baffled cooling crystallizer in batch mode which was further linearly scaled-up to

continuous cocrystallization. The TPD of α-lipoic acid and nicotinamide in the mixed solvent

of isopropanol/hexane was constructed to identify the critical region in which crystallization of

pure cocrystal occurs while the influence of the temperature in the critical region was also

27

investigated. Based on the TPD, the starting concentration of α-lipoic acid, nicotinamide and

the cooling profiles were selected to ensure that crystallization would take place within the

critical region increasing the purity of the final product and the yield of the process. During

continuous cocrystallization, solid content and particle size distributions were monitored using

a FBRM probe. The continuous crystallization process used resulted in over 1 kg of high purity

solid cocrystals at a throughput of 350 gh-1. This study demonstrated that combining continuous

processing with a systematic approach to design holds a great potential as an effective and rapid

route towards scaling-up of novel cocrystals.

Polymorphic cocrystal systems are particularly challenging systems as different polymorphs

often crystallize together as a mixture, making the isolation of the desired polymorphic form

difficult. Powell et al., selected the polymorphic urea-barbituric acid cocrystal system and

investigated polymorph control in cooling crystallization applying the concept of periodic flow

crystallization by using a novel crystallizer based on periodic mixed suspension mixed product

removal (PMSMPR) [134]. The PMSMPR operation involves controlled disruptions applied to

the inlet and outlet flow of an otherwise continuous mixed suspension mixed product removal

(MSMPR) crystalliser and it was found to be a promising strategy for the isolation of pure

polymorphic form of a cocrystal in the pharmaceutical industry. Moreover, in this study the

crystallization process was monitored using a composite sensor array (CSA) consisting of

FBRM, ATR-UV/Vis, particle vision and measurement (PVM) and Raman probe. Use of CSA

is an emerging area in crystallization monitoring as it allows information from different PAT

sensors to be combined and applied for automated decision support and feedback control of the

crystallization process (Fig. 7) [135].

28

6. Concluding remarks

The knowledge of phase diagrams (PSD and TPDs) has provided fundamental understanding

of cocrystal stabilities in solutions. Recently, experimental screening methods which rely on

phase diagrams, such as liquid assisted grinding and slurring or reaction crystallization, have

evolved as efficient and widely used cocrystal screening methods. In combination with in-silico

and semi-empirical methods, the implementation of rational screening methods has enhanced

the cocrystal screening efficiency that brought to light previously unknown cocrystals. Initial

reports on cocrystals preparation had only considered “gram” quantities for the purpose of

pharmaceutical characterization and in vivo studies. In most of the studies, solvent evaporation

crystallization of equimolar mixture of the API and conformer was performed to obtain gram

quantities, without much consideration to cocrystal phase diagrams. However, the need for the

implementation of QbD paradigm in pharmaceutical manufacturing processes has compelled

the development of science-based tools like phase diagrams in the crystallization process

development. Few subsequent studies have successfully employed phase diagrams and PAT

tools in scaling-up cocrystals in “kilogram” scale using cooling or cooling/anti-solvent batch

crystallization methods. Currently, the development of continuous crystallization methods for

cocrystals is an emerging area. Recent studies have provided perspectives on the potential

advantages of continuous crystallization and challenges involved in the form control. It is

emphasized that proper understanding of cocrystal phase behaviour is crucial in developing

continuous crystallization processes and for the quality of final product. Thus, solution phase

diagrams provide profound scientific basis and rationality in designing cocrystal screening and

scale-up processes, that eventually lead to rational experimental screening methods and robust

scale-up crystallization processes.

29

Funding sources

This research did not receive any specific grant from funding agencies in the public,

commercial, or not-for-profit sectors.

30

Referensi

[1]

J. Aaltonen, M. Allesø, S. Mirza, V. Koradia, KC Gordon, J. Rantanen, Solid form screening A review, Eur. J. Pharm. Biofarm. 71 (2009) 23–37. doi:10.1016/j.ejpb.2008.07.014.

[2]

N. Shan, MJ Zaworotko, The role of cocrystals in pharmaceutical science, Drug Discov. Today.

13 (2008) 440–446. doi:http://dx.doi.org/10.1016/j.drudis.2008.03.004.

[3]

A. Newman, X-ray Powder Diffraction in Solid Form Screening and Selection, Am. Pharm Rev.

14 (2011).

[4]

A. Newman, Specialized solid form screening techniques, Org. Proses Res. Dev. 17 (2013) 457–

471. doi:10.1021/op300241f.

[5]

B. Sarma, J. Chen, HY Hsi, AS Myerson, Solid forms of pharmaceuticals: Polymorphs, salts and

cocrystals, Korean J. Chem. Eng 28 (2011) 315–322. doi:10.1007/s11814-010-0520-0.

[6]

ML Cheney, DR Weyna, N. Shan, M. Hanna, L. Wojtas, MJ Zaworotko, Coformer selection in

pharmaceutical cocrystal development: A case study of a meloxicam aspirin cocrystal that

exhibits enhanced solubility and pharmacokinetics, J. Pharm. Sci. 100 (2011) 2172–2181.

doi:10.1002/jps.22434.

[7]

N. Wyttenbach, C. Janas, M. Siam, ME Lauer, L. Jacob, E. Scheubel, S. Page, Miniaturized

screening of polymers for amorphous drug stabilization (SPADS): Rapid assessment of solid

dispersion

systems,

Eur.

J.

Pharm.

Biofarm.

84

(2013)

583–598.

doi:10.1016/j.ejpb.2013.01.009.

[8]

R. Dubey, GR Desiraju, Combinatorial selection of molecular conformations and

supramolecular synthons in quercetin cocrystal landscapes: A route to ternary solids, IUCrJ. 2

(2015) 402–408. doi:10.1107/S2052252515009884.

[9]

T. Grecu, H. Adams, CA Hunter, JF McCabe, A. Portell, R. Prohens, Virtual screening identifies

new cocrystals of nalidixic acid, Cryst. Growth Des. 14 (2014) 1749–1755.

doi:10.1021/cg401889h.

[10]

A. Fernández Casares, WM Nap, G. Ten Figás, P. Huizenga, R. Groot, M. Hoffmann, An

evaluation of salt screening methodologies, J. Pharm. Farmakol 67 (2015) 812–822.

doi:10.1111/jphp.12377.

[11]

MD Eddleston, S. Sivachelvam, W. Jones, Screening for polymorphs of cocrystals: a case study,

CrystEngComm. 15 (2013) 175–181. doi:10.1039/C2CE26496J.

[12]

GP Stahly, Diversity in single- and multiple-component crystals. the search for and prevalence

of polymorphs and cocrystals, Cryst. Growth Des. 7 (2007) 1007–1026. doi:10.1021/cg060838j.

[13]

DD Gadade, SS Pekamwar, Pharmaceutical cocrystals: Regulatory and strategic aspects, design

and development, Adv. Pharm Banteng. 6 (2016) 479–494. doi:10.15171/apb.2016.062.

[14]

M. Allesø, F. Van Den Berg, C. Cornett, FS Jørgensen, B. Halling-Sørensen, HL De Diego,

L. Hovgaard, J. Aaltonen, J. Rantanen, Solvent diversity in polymorph screening, J. Pharm. Sci.

31

97 (2008) 2145–2159. doi:10.1002/jps.21153.

[15]

Z. Zhou, HM Chan, HH-Y. Sung, HHY Tong, Y. Zheng, Identification of New Cocrystal

Systems with Stoichiometric Diversity of Salicylic Acid Using Thermal Methods, Pharm. Res.

33 (2016) 1030–1039. doi:10.1007/s11095-015-1849-1.

[16]

EH Lee, A practical guide to pharmaceutical polymorph screening & selection, Asian J. Pharm.

Sci. 9 (2014) 163–175. doi:10.1016/j.ajps.2014.05.002.

[17]

SL Morissette, Ö. Almarsson, ML Peterson, JF Remenar, MJ Read, AV Lemmo, S. Ellis, MJ

Cima, CR Gardner, High-throughput crystallization: Polymorphs, salts, co-crystals and solvates

of pharmaceutical solids, Adv. Obat Deliv. Rev. 56 (2004) 275–300.

doi:10.1016/j.addr.2003.10.020.

[18]

M. Kitamura, M. Sugimoto, Anti-solvent crystallization and transformation of thiazolederivative

polymorphs - I: Effect of addition rate and initial concentrations, J. Cryst. Growth. 257 (2003)

177–184. doi:10.1016/S0022-0248(03)01424-6.

[19]

I. Weissbuch, M. Lahav, L. Leiserowitz, Toward stereochentical control, monitoring, and

understanding of crystal nucleation, Cryst. Growth Des. 3 (2003) 125–150.

[20]

CH Gu, H. Li, RB Gandhi, K. Raghavan, Grouping solvents by statistical analysis of solvent

property parameters: Implication to polymorph screening, Int. J. Pharm. 283 (2004) 117–125.

doi:10.1016/j.ijpharm.2004.06.021.

[21]

B. Samas, C. Seadeek, AM Campeta, BP Chekal, A thermodynamic-based approach to analyzing

a highly solvating polymorphic system: The desolvation window method, J. Pharm. Sci. 100

(2011) 186–194. doi:10.1002/jps.22265.

[22]

YA Abramov, C. Loschen, A. Klamt, Rational coformer or solvent selection for pharmaceutical

cocrystallization or desolvation, J. Pharm. Sci. 101 (2012) 3687–3697. doi:10.1002/jps.23227.

[23]

JM Miller, BM Collman, LR Greene, DJW Grant, AC Blackburn, Identifying the Stable

Polymorph Early in the Drug Discovery–Development Process, Pharm. Dev. Technol. 10 (2005)

291–297. doi:10.1081/PDT-54467.

[24]

H. Qu, M. Louhi-Kultanen, J. Kallas, Solubility and stability of anhydrate/hydrate in solvent

mixtures, Int. J. Pharm. 321 (2006) 101–107. doi:10.1016/j.ijpharm.2006.05.013.

[25]

J. Cao, Numerical simulation of DSC and TMDSC curves as well as reversing and nonreversing

curve separation, J. Appl. Polym. Sci. 106 (2007) 3063–3069. doi:10.1002/app.26787.

[26]

RJ Behme, D. Brooke, Heat of fusion measurement of a low melting polymorph of

carbamazepine that undergoes multiple phase changes during differential scanning calorimetry

analysis, J. Pharm. Sci. 80 (1991) 986–990. doi:10.1002/jps.2600801016.

[27]

D. Grooff, MM De Villiers, W. Liebenberg, Thermal methods for evaluating polymorphic

transitions in nifedipine, Thermochim. Acta. 454 (2007) 33–42. doi:10.1016/j.tca.2006.12.009.

32

[28]

J. Li, SA Bourne, MM de Villiers, AM Crider, MR Caira, Polymorphism of the Antitubercular

Isoxyl, Cryst. Growth Des. 11 (2011) 4950–4957. doi:10.1021/cg200860p.

[29]

Y. Park, J. Lee, SH Lee, HG Choi, C. Mao, SK Kang, SE Choi, EH Lee, Crystal structures of

tetramorphic forms of donepezil and energy/temperature phase diagram via direct heat capacity

measurements, Cryst. Growth Des. 13 (2013) 5450–5458. doi:10.1021/cg401405g.

[30]

V. Saxena, R. Panicucci, Y. Joshi, S. Garad, Developability assessment in pharmaceutical

industry: An integrated group approach for selecting developable candidates, J. Pharm. Sci. 98

(2009) 1962–1979. doi:10.1002/jps.21592.

[31]

C. Saal, A. Becker, Pharmaceutical salts: A summary on doses of salt formers from the Orange

Book, Eur. J. Pharm. Sci. 49 (2013) 614–623. doi:10.1016/j.ejps.2013.05.026.

[32]

MH Abraham, PL Grellier, D. V Prior, JJ Morris, PJ Taylor, Hydrogen bonding. Part 10. A scale

of solute hydrogen-bond basicity using log K values for complexation in tetrachloromethane, J.

Chem. Soc.{,} Perkin Trans. 2. (1990) 521–529. doi:10.1039/P29900000521.

[33]

P. Gilli, L. Pretto, V. Bertolasi, G. Gilli, Predicting Hydrogen-Bond Strengths from Acid - Base

Molecular Properties . The p K a Slide Rule : Toward the Solution of a Long-Lasting Problem,

42 (2009) 33–44.

[34]

S. Mohamed, DA Tocher, M. Vickers, PG Karamertzanis, SL Price, Salt or cocrystal? A new

series of crystal structures formed from simple pyridines and carboxylic acids, Cryst. Growth

Des. 9 (2009) 2881–2889. doi:10.1021/cg9001994.

[35]

TS Wiedmann, A. Naqwi, Pharmaceutical salts: Theory, use in solid dosage forms and in situ

preparation in an aerosol, Asian J. Pharm. Sci. 11 (2016) 722–734.

doi:10.1016/j.ajps.2016.07.002.

[36]

AV Trask, DA Haynes, WDS Motherwell, W. Jones, Screening for crystalline salts via

mechanochemistry, Chem. Komunal. (2006) 51–53. doi:10.1039/B512626F.

[37]

X. Liu, L. Zhou, F. Zhang, Reactive Melt Extrusion To Improve the Dissolution Performance

and Physical Stability of Naproxen Amorphous Solid Dispersions, Mol. Pharm 14 (2017) 658–

673. doi:10.1021/acs.molpharmaceut.6b00960.

[38]

D. Hasa, D. Voinovich, B. Perissutti, M. Grassi, A. Bonifacio, V. Sergo, C. Cepek, MR

Chierotti, R. Gobetto, S. Dall'Acqua, S. Invernizzi, Enhanced oral bioavailability of vinpocetine

through mechanochemical salt formation: Physico-chemical characterization and in vivo studies,

Pharm. Res. 28 (2011) 1870–1883. doi:10.1007/s11095-011-0415-8.

[39]

S. Aitipamula, R. Banerjee, AK Bansal, K. Biradha, ML Cheney, AR Choudhury, GR Desiraju,

AG Dikundwar, R. Dubey, N. Duggirala, PP Ghogale, S. Ghosh, PK Goswami, NR Goud,

RRKR Jetti, P. Karpinski, P. Kaushik, D. Kumar, V. Kumar, B. Moulton, A. Mukherjee, G.

Mukherjee, AS Myerson, V. Puri, A. Ramanan, T. Rajamannar, CM Reddy, N. RodriguezHornedo, RD Rogers, TNG Row, P. Sanphui, N. Shan, G. Shete, A. Singh, CC Sun, JA Swift,

R. Thaimattam, TS Thakur, R. Kumar Thaper, SP Thomas, S. Tothadi, VR Vangala, N.

Variankaval, P. Vishweshwar, DR Weyna, MJ Zaworotko, Polymorphs, salts, and cocrystals:

What's in a name?, Cryst. Growth Des. 12 (2012) 2147–2152. doi:10.1021/cg3002948.

33

[40]

SA Ross, DA Lamprou, D. Douroumis, Engineering and manufacturing of pharmaceutical cocrystals: a review of solvent-free manufacturing technologies, Chem. Komunal. 52 (2016) 8772–

8786. doi:10.1039/C6CC01289B.

[41]

PM Bhatt, GR Desiraju, Co-crystal formation and the determination of absolute configuration,

CrystEngComm. 10 (2008) 1747–1749. doi:10.1039/B810643F.

[42]

M. Hemamalini, W.-S. Loh, C. Quah, H.-K. Fun, Investigation of supramolecular synthons and

structural characterisation of aminopyridine-carboxylic acid derivatives, Chem. Cent. J. 8 (2014)

31. doi:10.1186/1752-153X-8-31.

[43]

PA Wood, N. Feeder, M. Furlow, PTA Galek, CR Groom, E. Pidcock, Knowledge-based

approaches to co-crystal design, CrystEngComm. 16 (2014) 5839. doi:10.1039/c4ce00316k.

[44]

MC Etter, SM Reutzel, Hydrogen bond directed cocrystallization and molecular recognition

properties of acyclic imides, J. Am. Chem Soc. 113 (1990) 2586–2598.

doi:10.1021/ja00007a037.

[45]

A. Lemmerer, DA Adsmond, C. Esterhuysen, J. Bernstein, Polymorphic co-crystals from

polymorphic co-crystal formers: Competition between carboxylic acid···pyridine and

phenol···pyridine hydrogen bonds, Cryst. Growth Des. 13 (2013) 3935–3952.

doi:10.1021/cg4006357.

[46]

CR Groom, FH Allen, The Cambridge Structural Database in retrospect and prospect, Angew.

Chemie - Int. Ed. 53 (2014) 662–671. doi:10.1002/anie.201306438.

[47]

S. Basavoju, D. Bostrom, P. Velaga, Pharmaceutical cocrystals and salts of Norfloxacin, Cryst.

Growth Des. 6 (2006) 2699–2708. doi:10.1021/cg060327x.

[48]

IJ Bruno, CR Groom, A crystallographic perspective on sharing data and knowledge, J. Comput.

Aided. Mol. Des. 28 (2014) 1015–1022. doi:10.1007/s10822-014-9780-9.

[49]

A. Delori, PTA Galek, E. Pidcock, M. Patni, W. Jones, Knowledge-based hydrogen bond

prediction and the synthesis of salts and cocrystals of the anti-malarial drug pyrimethamine with

various drug and GRAS molecules, CrystEngComm. 15 (2013) 2916. doi:10.1039/c3ce26765b.

[50]

AM Moragues-Bartolome, W. Jones, AJ Cruz-Cabeza, Synthon preferences in cocrystals of ciscarboxamides:

carboxylic

acids,

Crystengcomm.

14

(2012)

2552–2559.

doi:10.1039/c2ce06241k.

[51]

TS Thakur, GR Desiraju, Crystal structure prediction of a co-crystal using a supramolecular

synthon approach: 2-Methylbenzoic acid-2-amino-4-methylpyrimidine, Cryst. Growth Des. 8

(2008) 4031–4044. doi:10.1021/cg800371j.

[52]

J. van de Streek, Searching the Cambridge Structural Database for the `best' representative of

each unique polymorph, Acta Crystallogr. Sect. B. 62 (2006) 567–579.

doi:10.1107/S0108768106019677.

[53]

A. Lemmerer, C. Esterhuysen, J. Bernstein, Synthesis, characterization, and molecular modeling

of a pharmaceutical co-crystal: (2-Chloro-4-nitrobenzoic acid):(Nicotinamide), J. Pharm. Sci.

34

99 (2010) 4054–4071. doi:10.1002/jps.22211.

[54]

H. Yamashita, Y. Hirakura, M. Yuda, T. Teramura, K. Terada, Detection of Cocrystal Formation

Based on Binary Phase Diagrams Using Thermal Analysis, Pharm. Res. 30 (2013) 70–80.

doi:10.1007/s11095-012-0850-1.

[55]

H. Yamashita, Y. Hirakura, M. Yuda, K. Terada, Coformer Screening Using Thermal Analysis

Based on Binary Phase Diagrams, Pharm. Res. (2014) 1–12. doi:10.1007/s11095-014-1296-4.

[56]

E. Lu, N. Rodríguez-Hornedo, R. Suryanarayanan, A rapid thermal method for cocrystal

screening, CrystEngComm. 10 (2008) 665. doi:10.1039/b801713c.

[57]

A. Shayanfar, A. Jouyban, Physicochemical characterization of a new cocrystal of ketoconazole,

Powder Technol. 262 (2014) 242–248. doi:10.1016/j.powtec.2014.04.072.

[58]

AO Surov, KA Solanko, AD Bond, A. Bauer-brandl, GL Perlovich, formation thermodynamics

and lattice energies †, CrystEngComm. 18 (2016) 4818–4829. doi:10.1039/C6CE00931J.

[59]

AN Manin, AP Voronin, KV Drozd, NG Manin, A. Bauer-Brandl, GL Perlovich, Cocrystal

screening of hydroxybenzamides with benzoic acid derivatives: A comparative study of thermal

and

solution-based

methods,

Eur.

J.

Pharm.

Sci.

65

(2014)

56–64.

doi:10.1016/j.ejps.2014.09.003.

[60]

DJ Berry, CC Seaton, W. Clegg, RW Harrington, SJ Coles, PN Horton, MB Hursthouse, R.

Storey, W. Jones, T. Friščić, N. Blagden, Applying hot-stage microscopy to co-crystal screening:

A study of nicotinamide with seven active pharmaceutical ingredients, Cryst. Growth Des. 8

(2008) 1697–1712. doi:10.1021/cg800035w.

[61]

C. Hong, Y. Xie, Y. Yao, G. Li, X. Yuan, H. Shen, A Novel strategy for pharmaceutical cocrystal

generation without knowledge of stoichiometric ratio: Myricetin cocrystals and a ternary phase

diagram, Pharm. Res. 32 (2015) 47–60. doi:10.1007/s11095-014-1443-y.

[62]

MA Mohammad, A. Alhalaweh, SP Velaga, Hansen solubility parameter as a tool to predict

cocrystal formation, Int. J. Pharm. 407 (2011) 63–71. doi:10.1016/j.ijpharm.2011.01.030.

[63]

JH Ter Horst, MA Deij, PW Cains, Discovering new co-crystals, Cryst. Growth Des. 9 (2009)

1531–1537. doi:10.1021/cg801200h.

[64]

K. Greco, R. Bogner, Solution-mediated phase transformation: Significance during dissolution

and implications for bioavailability, J. Pharm. Sci. 101 (2012) 2996–3018.

doi:10.1002/jps.23025.

[65]

N. Rodríguez-Hornedo, SJ Nehm, KF Seefeldt, Y. Pagán-Torres, CJ Falkiewicz, Reaction

crystallization of pharmaceutical molecular complexes, Mol. Pharm 3 (2006) 362–367.

doi:10.1021/mp050099m.

[66]

GGZ Zhang, RF Henry, TB Borchardt, X. Lou, Efficient co-crystal screening using solutionmediated phase transformation, J. Pharm. Sci. 96 (2007) 990–995. doi:10.1002/jps.20949.

35

[67]

DK Bučar, RF Henry, GGZ Zhang, LR Macgillivray, Synthon hierarchies in crystal forms

composed of theophylline and hydroxybenzoic acids: Cocrystal screening via solution-mediated

phase transformation, Cryst. Growth Des. 14 (2014) 5318–5328. doi:10.1021/cg501204k.

[68]

N. Takata, K. Shiraki, R. Takano, Y. Hayashi, K. Terada, Cocrystal screening of stanolone and

mestanolone using slurry crystallization, Cryst. Growth Des. 8 (2008) 3032–3037.

doi:10.1021/cg800156k.

[69]

DK Bučar, RF Henry, X. Lou, RW Duerst, LR MacGillivray, GGZ Zhang, Cocrystals of caffeine

and hydroxybenzoic acids composed of multiple supramolecular heterosynthons: Screening via

solution-mediated phase transformation and structural characterization, Cryst. Growth Des. 9

(2009) 1932–1943. doi:10.1021/cg801178m.

[70]

SL Childs, N. Rodríguez-Hornedo, LS Reddy, A. Jayasankar, C. Maheshwari, L. McCausland,