Uploaded by

sufrotun.kimia

Correlations of Physical Properties in Mono- and Di-Saccharide Solutions

advertisement

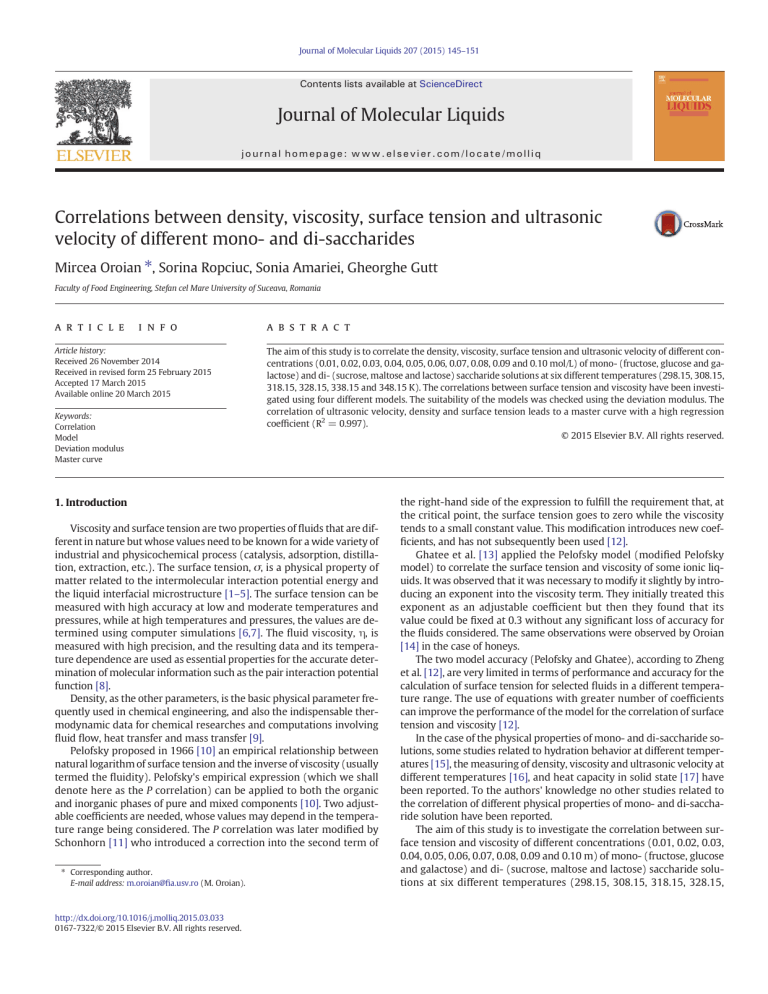

Journal of Molecular Liquids 207 (2015) 145–151 Contents lists available at ScienceDirect Journal of Molecular Liquids journal homepage: www.elsevier.com/locate/molliq Correlations between density, viscosity, surface tension and ultrasonic velocity of different mono- and di-saccharides Mircea Oroian ⁎, Sorina Ropciuc, Sonia Amariei, Gheorghe Gutt Faculty of Food Engineering, Stefan cel Mare University of Suceava, Romania a r t i c l e i n f o Article history: Received 26 November 2014 Received in revised form 25 February 2015 Accepted 17 March 2015 Available online 20 March 2015 Keywords: Correlation Model Deviation modulus Master curve a b s t r a c t The aim of this study is to correlate the density, viscosity, surface tension and ultrasonic velocity of different concentrations (0.01, 0.02, 0.03, 0.04, 0.05, 0.06, 0.07, 0.08, 0.09 and 0.10 mol/L) of mono- (fructose, glucose and galactose) and di- (sucrose, maltose and lactose) saccharide solutions at six different temperatures (298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K). The correlations between surface tension and viscosity have been investigated using four different models. The suitability of the models was checked using the deviation modulus. The correlation of ultrasonic velocity, density and surface tension leads to a master curve with a high regression coefficient (R2 = 0.997). © 2015 Elsevier B.V. All rights reserved. 1. Introduction Viscosity and surface tension are two properties of fluids that are different in nature but whose values need to be known for a wide variety of industrial and physicochemical process (catalysis, adsorption, distillation, extraction, etc.). The surface tension, σ, is a physical property of matter related to the intermolecular interaction potential energy and the liquid interfacial microstructure [1–5]. The surface tension can be measured with high accuracy at low and moderate temperatures and pressures, while at high temperatures and pressures, the values are determined using computer simulations [6,7]. The fluid viscosity, η, is measured with high precision, and the resulting data and its temperature dependence are used as essential properties for the accurate determination of molecular information such as the pair interaction potential function [8]. Density, as the other parameters, is the basic physical parameter frequently used in chemical engineering, and also the indispensable thermodynamic data for chemical researches and computations involving fluid flow, heat transfer and mass transfer [9]. Pelofsky proposed in 1966 [10] an empirical relationship between natural logarithm of surface tension and the inverse of viscosity (usually termed the fluidity). Pelofsky's empirical expression (which we shall denote here as the P correlation) can be applied to both the organic and inorganic phases of pure and mixed components [10]. Two adjustable coefficients are needed, whose values may depend in the temperature range being considered. The P correlation was later modified by Schonhorn [11] who introduced a correction into the second term of ⁎ Corresponding author. E-mail address: m.oroian@fia.usv.ro (M. Oroian). http://dx.doi.org/10.1016/j.molliq.2015.03.033 0167-7322/© 2015 Elsevier B.V. All rights reserved. the right-hand side of the expression to fulfill the requirement that, at the critical point, the surface tension goes to zero while the viscosity tends to a small constant value. This modification introduces new coefficients, and has not subsequently been used [12]. Ghatee et al. [13] applied the Pelofsky model (modified Pelofsky model) to correlate the surface tension and viscosity of some ionic liquids. It was observed that it was necessary to modify it slightly by introducing an exponent into the viscosity term. They initially treated this exponent as an adjustable coefficient but then they found that its value could be fixed at 0.3 without any significant loss of accuracy for the fluids considered. The same observations were observed by Oroian [14] in the case of honeys. The two model accuracy (Pelofsky and Ghatee), according to Zheng et al. [12], are very limited in terms of performance and accuracy for the calculation of surface tension for selected fluids in a different temperature range. The use of equations with greater number of coefficients can improve the performance of the model for the correlation of surface tension and viscosity [12]. In the case of the physical properties of mono- and di-saccharide solutions, some studies related to hydration behavior at different temperatures [15], the measuring of density, viscosity and ultrasonic velocity at different temperatures [16], and heat capacity in solid state [17] have been reported. To the authors' knowledge no other studies related to the correlation of different physical properties of mono- and di-saccharide solution have been reported. The aim of this study is to investigate the correlation between surface tension and viscosity of different concentrations (0.01, 0.02, 0.03, 0.04, 0.05, 0.06, 0.07, 0.08, 0.09 and 0.10 m) of mono- (fructose, glucose and galactose) and di- (sucrose, maltose and lactose) saccharide solutions at six different temperatures (298.15, 308.15, 318.15, 328.15, 146 M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 338.15 and 348.15 K) using four models, and the correlation between surface tension, density and ultrasonic velocity in the same conditions. where n is the total number of data. Subscripts exp. and cal. denote experimental and calculated values, respectively. X represents viscosity, η, or surface tension, σ. 2. Materials and methods 3. Results and discussions 2.1. Materials For this study, six different mono- and di-saccharides: fructose, glucose, galactose, maltose, lactose and sucrose at different molar concentrations (0.01 to 0.10 mol/L) were analyzed. All the mono- and di-saccharides were purchased from Sigma Aldrich (Germany). The solutions were prepared using double deionized water. Double deionized water (18 MΩ cm resistivity) produced by a water purification system (Thermofisher, Germany) was used in all solutions. 2.2. Density measurements Density (ρ) of the samples was measured using a pycnometer with an accuracy 10−4 kg/m3. The calibration of a pycnometer was made with ultrapure water. Temperature was kept constant within ±0.01 K using a PID controller and circulating water using a thermostatic-fluid bath. The density of the samples was measured at 298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K. The values of parameters were expressed as the mean ± standard deviation to a confidence interval for mean of 95%. The ultrasonic velocity measurement was carried out using a flow detector USM 35X (GE Measurement and Control, USA) with a dualelement (TR) probe working at 4 MHz. The measurements were carried out at 298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K. The values of parameters were expressed as the mean ± standard deviation to a confidence interval for mean of 95 %. 2.4. Viscosity measurement Viscosity measurements were carried out on the samples at different temperatures (298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K), with an Ubbelohde viscometer and a temperature controlled water bath (uncertainty 0.26%). The sample was allowed to reach the desired temperature for 20 min. Each measurement was taken in duplicate. The values of parameters were expressed as the mean ± standard deviation to a confidence interval for mean of 95%. 2.5. Surface tension determination The surface tension was computed using Auerbach's equation: [18] u¼ σ 6:33 10−10 ρ 2=3 ð1Þ where u is the ultrasonic velocity (m/s), σ is the surface tension in N/m and ρ is the density in kg/m3. Therefore, for the calculation of the surface tension, first we measured the ultrasonic velocity and density and later on by using the Auerbach equation we were able to compute the surface tension. 2.6. Prediction accuracy The mean relative deviation modulus, D, was used to verify the suitability of model for experimental data: 100 Xn X exp;i −Xcal;i D% ¼ i¼1 n X exp;i 3.1. Influence of temperature and concentration on the viscosity The saccharide solution viscosity has been measured using the Ubbelohde viscometer at different temperatures (298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K). It can be observed in Fig. 1 that the solution viscosity is influenced positively by the concentration and negatively by the temperature. Correlations were made to allow the prediction of viscosity of the honey samples. The correlations of viscosity were as a function of temperature or honey concentration using polynomial fitting by means of the experimental data. The following expressions were used for the regression equations of the experimental data: η¼aþbT þ f T 2.3. Ultrasonic velocity measurement The physical parameters (ultrasonic velocity, density, viscosity and surface tension) have been analyzed at different temperatures (298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K, with a temperature accuracy of 0.01 K). The physical parameter values in function of temperatures and concentrations are presented in Tables 1–4. ð2Þ 2 η ¼ d þ e cM þ f cM ð3Þ 2 ð4Þ where η is the viscosity in N·s·m−2, T is the temperature in K, cM is the molar concentration (mol/L) and a–f are the fitting parameters. The regression coefficients for both models ranged between 0.961 and 0.997. The values of a ranged between 1.718 · 10−3 and 1.953 · 10−3, b ranged between − 0.04289 · 10− 3, and c ranged between 0.00026 · 10−3 and 0.00029 · 10−3, respectively. The a and c are positively influenced by the concentration (r = 0.835*** and r = 0.781, respectively) and b is not influenced significantly by the temperature (r = −0.044 ns). The parameters d of Eq. (4) ranged between 0.245 · 10− 3 and 0.944 · 10−3, e ranged between 0.180 · 10−3 and 1.038 · 10−3 and f ranged between 0.290 · 10− 3 and 1.117 · 10− 3, respectively. The d and e are negatively influenced by the temperature (r = − 0.957*** and r = − 0.877, respectively) and f is positively influenced by the temperature (r = 0.904***). The mean deviation modulus between the prediction and experimental values and average ranged between 0.172% and 0.564%. 3.2. Influence of temperature and concentration on the surface tension The solution surface tension (computed using the Auerbach relation) ranged between 0.030 and 0.038 N/m. A linear evolution of the surface tension with temperature (Fig. 2) can be observed. The evolution of the surface tension with temperature was subjected to linear regression to see its prediction using the following equation: σ ¼gþhT þiT 2 ð5Þ where σ — surface tension in N/m, g, h and i are constants, and T — temperature (K). In Fig. 2, the evolution of surface tension and solution concentration for glucose is presented. The g values ranged between 0.040 and 0.041, h ranged between − 0.00015 and − 0.00016, while i ranged between 1.96 · 10−7 and 2.00 · 10−7. The g and i values are influenced positively by the concentration (r = 0.977*** and r = 0.926*** respectively), and h is influenced negatively by the concentration (r = −0.945***). M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 Table 1 Ultrasonic velocity (u, m/s) evolution with temperature. C (mol/L) Table 2 Density (ρ, kg/m3) evolution with temperature. u (m/s) Glucose C (mol/L) Fructose Galactose Sucrose Maltose Lactose ρ (kg/m3) Glucose Fructose Galactose Sucrose Maltose Lactose 1501.8 1503.4 1505.2 1507.0 1508.8 1510.5 1512.3 1514.0 1515.5 1517.1 298.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 998.20 998.80 999.60 1004.40 1001.00 1001.60 1002.00 1002.70 1003.30 1003.90 1000.40 1001.00 1001.80 1002.60 1003.40 1004.10 1004.70 1005.20 1005.90 1006.70 1001.00 1001.60 1002.30 1002.90 1003.50 1004.20 1004.80 1005.60 1006.20 1006.90 1021.02 1021.63 1022.35 1022.96 1023.57 1024.28 1024.90 1025.71 1026.32 1027.04 1002.29 1002.89 1003.59 1004.19 1004.80 1005.50 1006.10 1006.90 1007.50 1008.20 1003.19 1003.79 1004.49 1005.09 1005.69 1006.39 1007.00 1007.80 1008.40 1009.10 1468.2 1469.8 1471.5 1473.3 1475.0 1476.7 1478.5 1480.1 1481.6 1483.2 1470.9 1472.5 1474.3 1476.0 1477.8 1479.4 1481.2 1482.9 1484.3 1485.9 308.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 990.21 990.81 991.60 996.36 992.99 993.59 993.98 994.68 995.27 995.87 992.40 992.99 993.79 994.58 995.37 996.07 996.66 997.16 997.85 998.65 992.99 993.59 994.28 994.88 995.47 996.17 996.76 997.56 998.15 998.84 1012.85 1013.46 1014.17 1014.77 1015.38 1016.09 1016.70 1017.51 1018.11 1018.82 994.27 994.87 995.57 996.16 996.76 997.45 998.05 998.84 999.44 1000.13 995.16 995.76 996.45 997.05 997.65 998.34 998.94 999.73 1000.33 1001.03 1445.0 1446.5 1448.2 1450.0 1451.7 1453.3 1455.1 1456.7 1458.1 1459.7 1438.0 1439.5 1441.3 1443.0 1444.7 1446.3 1448.1 1449.7 1451.1 1452.6 1440.7 1442.2 1443.9 1445.7 1447.4 1449.0 1450.7 1452.4 1453.8 1455.3 318.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 983.28 983.87 984.66 989.39 986.04 986.63 987.03 987.72 988.31 988.90 985.45 986.04 986.83 987.62 988.41 989.09 989.69 990.18 990.87 991.66 986.04 986.63 987.32 987.91 988.50 989.19 989.78 990.57 991.16 991.85 1005.76 1006.36 1007.07 1007.67 1008.27 1008.98 1009.58 1010.38 1010.99 1011.69 987.31 987.91 988.60 989.19 989.78 990.47 991.06 991.85 992.44 993.13 988.20 988.79 989.48 990.07 990.66 991.35 991.95 992.74 993.33 994.02 1412.4 1413.9 1415.6 1417.3 1419.0 1420.6 1422.3 1423.9 1425.3 1426.8 1415.3 1416.8 1418.5 1420.2 1421.8 1423.5 1425.1 1426.7 1428.2 1429.7 1408.4 1409.9 1411.6 1413.3 1415.0 1416.6 1418.3 1419.9 1421.3 1422.8 1411.0 1412.5 1414.2 1415.9 1417.6 1419.2 1420.9 1422.5 1423.9 1425.4 328.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 975.42 976.00 976.78 981.48 978.15 978.74 979.13 979.81 980.40 980.99 977.57 978.15 978.93 979.72 980.50 981.18 981.77 982.26 982.94 983.72 978.15 978.74 979.42 980.01 980.60 981.28 981.87 982.65 983.23 983.92 997.72 998.31 999.01 999.61 1000.21 1000.91 1001.50 1002.30 1002.90 1003.60 979.42 980.00 980.69 981.27 981.86 982.55 983.13 983.92 984.50 985.19 980.29 980.88 981.56 982.15 982.74 983.42 984.01 984.79 985.38 986.07 1383.5 1385.0 1387.0 1389.0 1390.7 1392.5 1394.1 1395.3 1397.0 1399.1 1383.4 1384.9 1386.5 1388.2 1389.8 1391.4 1393.0 1394.6 1396.0 1397.5 1386.2 1387.6 1389.3 1390.9 1392.6 1394.2 1395.8 1397.4 1398.8 1400.3 1379.5 1380.9 1382.6 1384.2 1385.9 1387.4 1389.1 1390.7 1392.0 1393.5 1382.0 1383.5 1385.1 1386.8 1388.5 1390.0 1391.7 1393.2 1394.6 1396.1 338.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 966.64 967.22 967.99 972.64 969.35 969.93 970.32 971.00 971.58 972.16 968.77 969.35 970.12 970.90 971.67 972.35 972.93 973.42 974.09 974.87 969.35 969.93 970.61 971.19 971.77 972.45 973.03 973.80 974.38 975.06 988.74 989.33 990.02 990.61 991.21 991.90 992.49 993.28 993.87 994.56 970.60 971.18 971.86 972.44 973.02 973.70 974.29 975.06 975.64 976.32 971.47 972.05 972.73 973.31 973.89 974.57 975.16 975.93 976.51 977.19 1353.7 1355.2 1357.1 1359.1 1360.8 1362.5 1364.0 1365.2 1366.9 1369.0 1353.6 1355.0 1356.7 1358.3 1359.9 1361.4 1363.1 1364.6 1365.9 1367.4 1356.3 1357.8 1359.4 1361.0 1362.6 1364.2 1365.8 1367.3 1368.7 1370.1 1349.8 1351.2 1352.8 1354.4 1356.1 1357.6 1359.2 1360.7 1362.1 1363.5 1352.3 1353.7 1355.3 1356.9 1358.6 1360.1 1361.7 1363.2 1364.6 1366.0 348.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 959.87 960.45 961.22 965.83 962.56 963.14 963.53 964.20 964.78 965.35 961.99 962.56 963.33 964.10 964.87 965.54 966.12 966.60 967.28 968.05 962.56 963.14 963.81 964.39 964.97 965.64 966.22 966.99 967.56 968.24 981.82 982.40 983.09 983.68 984.27 984.95 985.54 986.33 986.92 987.60 963.81 964.38 965.06 965.64 966.21 966.89 967.47 968.24 968.81 969.49 964.67 965.25 965.92 966.50 967.08 967.75 968.33 969.10 969.68 970.35 298.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1502.8 1504.6 1506.5 1508.7 1510.3 1512.1 1513.2 1515.0 1516.8 1518.2 1503.4 1505.1 1507.2 1509.4 1511.3 1513.2 1514.9 1516.2 1518.1 1520.4 1503.3 1504.9 1506.7 1508.5 1510.3 1512.0 1513.8 1515.5 1517.0 1518.6 1506.3 1507.9 1509.7 1511.5 1513.3 1515.0 1516.8 1518.5 1520.0 1521.6 1499.0 1500.6 1502.4 1504.2 1506.0 1507.7 1509.5 1511.2 1512.7 1514.3 308.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1471.9 1473.7 1475.5 1477.7 1479.2 1481.0 1482.1 1483.8 1485.6 1487.0 1472.5 1474.1 1476.2 1478.4 1480.2 1482.1 1483.7 1485.0 1486.9 1489.1 1472.4 1473.9 1475.7 1477.5 1479.2 1480.9 1482.7 1484.3 1485.8 1487.4 1475.3 1476.9 1478.7 1480.4 1482.2 1483.9 1485.6 1487.3 1488.8 1490.3 318.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1441.6 1443.3 1445.2 1447.3 1448.8 1450.5 1451.6 1453.3 1455.0 1456.4 1442.2 1443.8 1445.8 1447.9 1449.8 1451.6 1453.2 1454.5 1456.3 1458.5 1442.1 1443.6 1445.4 1447.1 1448.8 1450.4 1452.2 1453.8 1455.2 1456.8 328.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1412.0 1413.7 1415.4 1417.5 1419.0 1420.7 1421.7 1423.4 1425.1 1426.4 1412.5 1414.1 1416.1 1418.2 1420.0 1421.7 1423.3 1424.6 1426.3 1428.5 338.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1382.9 1384.6 1386.3 1388.4 1389.8 1391.5 1392.5 1394.2 1395.8 1397.1 348.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 1353.2 1354.8 1356.5 1358.5 1359.9 1361.5 1362.5 1364.1 1365.8 1367.0 u = 0.10%. 147 U = 0.09%. 148 M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 Table 3 Viscosity (η · 103, N·s/m2) evolution with temperature. C (mol/L) Table 4 Surface tension (σ, N/m) evolution with temperature. η · 103 (N·s/m2) Glucose C (mol/L) Glucose Fructose Galactose Sucrose Maltose Lactose 0.926 0.935 0.941 0.948 0.957 0.964 0.973 0.982 0.990 0.999 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.038 0.038 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.038 0.038 0.038 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.038 0.038 0.038 0.038 0.038 0.038 0.038 0.038 0.038 0.038 0.038 0.039 0.039 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.038 0.038 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.038 0.038 0.038 0.694 0.701 0.706 0.711 0.717 0.723 0.729 0.736 0.742 0.749 0.702 0.708 0.713 0.719 0.725 0.730 0.737 0.744 0.750 0.756 308.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.035 0.035 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.035 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.037 0.035 0.035 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.036 0.490 0.494 0.498 0.502 0.506 0.510 0.515 0.519 0.524 0.528 0.472 0.477 0.480 0.484 0.488 0.492 0.496 0.501 0.505 0.509 0.477 0.482 0.485 0.489 0.493 0.497 0.501 0.506 0.510 0.515 318.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.034 0.034 0.034 0.034 0.034 0.035 0.035 0.035 0.035 0.035 0.034 0.034 0.034 0.034 0.035 0.035 0.035 0.035 0.035 0.035 0.034 0.034 0.034 0.034 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.036 0.036 0.036 0.034 0.034 0.034 0.034 0.034 0.034 0.035 0.035 0.035 0.035 0.034 0.034 0.034 0.034 0.035 0.035 0.035 0.035 0.035 0.035 0.362 0.365 0.368 0.370 0.374 0.376 0.380 0.383 0.387 0.390 0.380 0.383 0.386 0.389 0.392 0.395 0.399 0.402 0.406 0.409 0.366 0.370 0.372 0.375 0.378 0.381 0.385 0.388 0.391 0.395 0.370 0.373 0.376 0.379 0.382 0.385 0.389 0.392 0.395 0.399 328.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.034 0.034 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.034 0.034 0.034 0.034 0.034 0.034 0.034 0.034 0.034 0.034 0.034 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.034 0.034 0.297 0.300 0.303 0.307 0.308 0.310 0.313 0.315 0.317 0.320 0.294 0.297 0.299 0.301 0.304 0.306 0.309 0.312 0.314 0.317 0.309 0.312 0.314 0.316 0.319 0.321 0.324 0.327 0.330 0.333 0.298 0.300 0.303 0.305 0.308 0.310 0.313 0.315 0.318 0.321 0.301 0.304 0.306 0.308 0.311 0.313 0.316 0.319 0.321 0.324 338.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.031 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.033 0.033 0.033 0.033 0.033 0.033 0.033 0.031 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.250 0.252 0.255 0.258 0.259 0.261-0.263 0.264 0.267 0.269 0.247 0.249 0.251 0.253 0.255 0.257 0.260 0.262 0.264 0.266 0.260 0.262 0.264 0.266 0.268 0.270 0.273 0.275 0.277 0.280 0.250 0.252 0.254 0.256 0.258 0.260 0.263 0.265 0.267 0.270 0.253 0.255 0.257 0.259 0.261 0.263 0.265 0.268 0.270 0.273 348.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.030 0.030 0.030 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.030 0.030 0.030 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.030 0.030 0.030 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.032 0.032 0.032 0.030 0.030 0.030 0.030 0.031 0.031 0.031 0.031 0.031 0.031 0.030 0.030 0.031 0.031 0.031 0.031 0.031 0.031 0.031 0.031 Galactose Sucrose Maltose 298.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.901 0.910 0.917 0.928 0.936 0.953 0.963 0.973 0.983 0.987 0.916 0.924 0.934 0.944 0.949 0.955 0.963 0.968 0.977 0.984 0.906 0.914 0.920 0.927 0.935 0.942 0.951 0.960 0.968 0.976 0.951 0.959 0.966 0.974 0.982 0.989 0.998 1.007 1.016 1.025 0.917 0.925 0.932 0.939 0.947 0.954 0.963 0.971 0.979 0.988 308.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.683 0.689 0.695 0.703 0.709 0.722 0.730 0.737 0.744 0.748 0.694 0.700 0.708 0.715 0.719 0.723 0.730 0.734 0.740 0.745 0.686 0.692 0.697 0.702 0.709 0.714 0.720 0.727 0.733 0.739 0.720 0.727 0.732 0.738 0.744 0.749 0.756 0.763 0.770 0.776 318.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.464 0.469 0.473 0.478 0.482 0.491 0.496 0.501 0.506 0.509 0.472 0.476 0.481 0.487 0.489 0.492 0.496 0.499 0.504 0.507 0.467 0.471 0.474 0.478 0.482 0.486 0.490 0.494 0.499 0.503 328.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.360 0.363 0.366 0.371 0.374 0.381 0.385 0.389 0.393 0.394 0.366 0.369 0.373 0.377 0.379 0.382 0.385 0.387 0.390 0.393 338.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.293 0.296 0.298 0.301 0.304 0.310 0.313 0.316 0.319 0.321 348.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.246 0.248 0.250 0.253 0.255 0.260 0.263 0.266 0.268 0.270 U = 0.26%. σ (N/m) 298.15 K 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 Fructose Lactose U = 0.10%. M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 a b 1.000 280.00 300.00 320.00 340.00 360.00 149 1.200 η·103 (N·s m-2) η·103 (N·s·m-2) 1.000 0.800 0.600 0.400 0.200 0.100 0.000 Temperature (K) 0 0.05 Concentration (mol/L) Fig. 1. Influence of temperature (a) and concentration: 0.01 mol/L, 0.02 mol/L, 0.03 mol/L, 0.04 mol/L, 0.05 mol/L, 0.10 mol/L (b) on glucose viscosity: 298.15 K, 308.15 K, 318.15 K, 328.15 K, 338.15 K and 348.15 K. b 0.039 0.038 0.037 0.036 0.035 0.034 0.033 0.032 0.031 0.030 0.07 mol/L, 0.08 mol/L, 0.09 mol/L and 0.040 0.038 σ (N/m) σ (N/m) a 0.06 mol/L, 0.1 0.036 0.034 0.032 280 300 320 340 Temperature (K) 360 0.030 0.00 0.02 0.04 0.06 0.08 Concentration (mol/L) Fig. 2. Influence of temperature (a) and concentration 0.01 mol/L, 0.02 mol/L, 0.03 mol/L, 0.04 mol/L, 0.05 mol/L, 0.10 mol/L (b) on glucose surface tension: 298.15 K, 308.15 K, 318.15 K, 328.15 K, 338.15 K and 348.15 K. Similarly, a correlation was developed to allow the prediction of the surface tension for the solutions as a function of molar concentration by means of 1st grade polynomial fitting. The following correlation is the regression equation: σ ¼ j þ k cM ð6Þ where σ — surface tension in N/m, cM — is the concentration expressed in mol/L, and j and k — fitting parameters. The regression coefficients were higher than 0.985. The values of j ranged between 0.030 and 0.036 and k ranged between 0.007 and 0.009. Both coefficients are negatively influenced by the temperature (r = −0.915***). The relative deviation modulus was lower than 0.5. 0.06 mol/L, 0.10 0.07 mol/L, 0.08 mol/L, 0.09 mol/L and The 3rd model applied is presented in Eq. (9): ln σ ¼ H þ F=ðη þ GÞ ð9Þ where E, F and G are the substance-dependent coefficients. The 4th model applied is presented in Eq. (10): 1=m ln σ ¼ H þ I= η þJ ð10Þ where H, J and m are the substance-dependent coefficients. The main goal of this article was to check the suitability of different models to correlate the surface tension and viscosity evolution of 3 mono- and 3 di-saccharides at ten different concentrations (0.01, 0.02, 0.03, 0.04, 0.05, 0.06, 0.07, 0.08, 0.09 and 0.10 mol/L). 3.3. Correlation between surface tension and viscosity In 1966, Pelofsky [10] proposed the first model for correlating the surface tension and viscosity: 0.03900 0.03800 0.03700 lnσ ¼ lnA þ B=η ð7Þ 0.03600 0.03500 where A and B are the adjusting parameters. The empirical relationship can be applied to both organic and inorganic pure fluids and mixtures. The second model applied for the saccharide surface tension–viscosity correlations was proposed by Ghatee et al. for ionic liquids [13]. The model (a modified Pelofsky model) expression is presented in Eq. (8): lnσ ¼ lnC þ D η −0:3 where C and D are substance-dependent coefficients. ð8Þ 0.03400 0.03300 0.03200 0.03100 0.03000 0.000 0.200 0.400 0.600 0.800 1.000 Fig. 3. Surface tension–viscosity evolution for the glucose solutions 308.15 K, 318.15 K, 328.15 K, 338.15 K and 348.15 K. 1.200 298.15 K, 150 M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 The data were fitted using the Multitab 17 trial version. The prediction accuracies of the four models have been checked computing the deviation modulus. The correlations between the surface tension and the Table 5 The relative deviation modulus for the surface tension correlation models. Concentration (mol/L) Pelofsky Modified Pelofsky Glucose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 3rd model 4th model 0.673 0.562 0.689 0.648 0.539 0.567 0.544 0.514 0.626 0.694 0.469 0.470 0.469 0.468 0.468 0.468 0.468 0.468 0.468 0.467 0.491 0.491 0.491 0.490 0.490 0.490 0.490 0.490 0.490 0.489 0.404 0.404 0.405 0.404 0.406 0.406 0.406 0.405 0.405 0.405 Fructose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.598 0.598 0.598 0.598 0.597 0.597 0.597 0.597 0.596 0.596 0.469 0.469 0.469 0.468 0.468 0.468 0.468 0.468 0.467 0.467 0.491 0.491 0.491 0.490 0.490 0.490 0.490 0.490 0.489 0489 0.405 0.405 0.406 0.406 0.406 0.405 0.405 0.405 0.405 0.405 Galactose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.598 0.598 0.598 0.597 0.597 0.597 0.597 0.597 0.596 0.597 0.469 0.469 0.469 0.468 0.468 0.468 0.468 0.467 0.467 0.467 0.491 0.491 0.491 0.490 0.490 0.490 0.490 0.489 0.489 0.489 0.404 0.404 0.404 0.404 0.405 0.406 0.406 0.405 0.405 0.405 Sucrose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.596 0.596 0.596 0.595 0.595 0.595 0.595 0.595 0.595 0.594 0.467 0.467 0.467 0.466 0.466 0.466 0.466 0.466 0.465 0.465 0.489 0.489 0.489 0.488 0.488 0.488 0.488 0.488 0.487 0.487 0.405 0.405 0.405 0.405 0.404 0.404 0.404 0.404 0.404 0.414 Maltose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.599 0.598 0.598 0.597 0.598 0.598 0.597 0.597 0.597 0.596 0.469 0.469 0.469 0.468 0.468 0.468 0.468 0.468 0.467 0.467 0.491 0.491 0.490 0.490 0.490 0.490 0.490 0.489 0.489 0.489 0.405 0.405 0.407 0.406 0.406 0.406 0.406 0.405 0.405 0.405 Lactose 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.598 0.598 0.598 0.598 0.597 0.597 0.597 0.597 0.596 0.596 0.469 0.469 0.469 0.468 0.468 0.468 0.468 0.467 0.467 0.467 0.491 0.491 0.491 0.490 0.490 0490 0.489 0.489 0.489 0.489 0.404 0.406 0.406 0.406 0.406 0.406 0.405 0.405 0.405 0.405 viscosity of the substances have been checked at different temperatures (298.15, 308.15, 318.15, 328.15, 338.15 and 348.15 K). In Fig. 3, the evolution of the surface tension with viscosity at different temperatures for the glucose solutions is presented. A logarithmic correlation between these two parameters is observed. In Table 5, the deviation modulus for the four models is presented. It seems that the small values of the deviation modulus are observed in the case of the 4th model, while the highest values are observed in the case of the Pelofsky model. The deviation modulus decreased in the next order: Pelofsky model N 3rd model N modified Pelofsky model N 4th model. The Pelofsky model is giving deviation modulus ranging between 0.596–0.694 and 0.465–0.470 in the case of modified Pelofsky model, 0.487–0.491 for the 3rd model and 0.404–0.415 for the 4th model, respectively. However all the four models can be considered suitable models because the deviation modules are lower than 1%. However the suitable model can be considered the 4th model, and the deviation modulus values are closed to 0.4%. 3.4. Correlations between density, ultrasonic velocity and surface tension The relation between the ultrasonic velocity, density and surface tension can be expressed using a linear equation as: [14] logu ¼ ψ logðσ=ρÞ þ ξ ð11Þ where u — ultrasonic velocity (m/s), σ — surface tension (N/m), ρ — density (kg/m3), and ψ and ξ — constants. All the three parameters of saccharide samples have been subjected to linear regression to assess the applicability of the equation and to compute the two constants. The ultrasonic velocity (log u)–density and surface tension (log (σ/ρ)) for all the saccharide samples analyzed are plotted in Fig. 4; it can be observed that the evolution of parameters is a linear one (the regression coefficients is R2 = 0.997), ψ = 0.667 and ξ = 6.132. We can conclude that the equation is a suitable one to correlate the ultrasonic velocity, density and surface tension for the monoand di-saccharides. 4. Conclusions All the physical parameters studied for the saccharide solutions (density, ultrasound velocity, surface tension and viscosity) are influenced negatively by the temperature increasing and positively by the concentration increasing, respectively. The 4th model used for the correlation of surface tension and viscosity (which employs four coefficients) is the suitable one for the prediction evolution. The correlation between density, ultrasonic velocity and surface tension of honey samples leads us to obtain a master curve for predicting these parameters with high accuracy (R2 = 0.997). Fig. 4. Correlation between ultrasound velocity, density and surface tension for mono- and di-saccharides. M. Oroian et al. / Journal of Molecular Liquids 207 (2015) 145–151 References [1] B.E. Poling, J.M. Prausnitz, J.P. O'Connell, The Properties of Gases and Liquids, 5th ed. McGraw-Hill, New York, 2001. [2] J.G. Kirkwood, F.P. Buff, The statistical mechanical theory of surface tension, J. Chem. Phys. 17 (1949) 338–343. [3] J.H. Irving, J.G. Kirkwood, The statistical mechanical theory of transport processes. IV. The equations of hydrodynamics, J. Chem. Phys. 18 (1950) 817–829. [4] F. Biscay, A. Ghoufi, P. Malfreyt, Surface tension of water–alcohol mixtures from Monte Carlo simulations, J. Chem. Phys. 134 (2011) 1–10. [5] A. Ghoufi, F. Goujon, V. Lachet, P. Malfreyt, Expressions for local contributions to the surface tension from the virial route, Phys. Rev. E 77 (2008) 031601. [6] J. Neyt, A. Wender, V. Lachet, P. Malfreyt, Prediction of the temperature dependence of the surface tension of SO2, N2, O2 and Ar by Monte Carlo molecular simulations, J. Phys. Chem. B 115 (2011) 9421–9430. [7] F. Biscay, A. Ghoufi, V. Lachet, P. Malfreyt, Prediction of the surface tension of the liquid–vapor interface of alcohols from Monte Carlo simulations, J. Phys. Chem. 115 (2011) 8670–8683. [8] C.M. Roland, S. Bair, R. Casalini, Thermodynamic scaling of the viscosity of van der Waals, H-bonded, and ionic liquids, J. Chem. Phys. 125 (2006) 1–8. [9] X. Jiang, C. Zhu, Y. Ma, Density and viscosity of sorbitol/maltitol in L-ascorbic acid aqueous solutions at T = (293.15 to 323.15) K, J. Mol. Liq. 188 (2013) 67–73. 151 [10] A.H. Pelofsky, Surface tension–viscosity relation for liquids, J. Chem. Eng. Data 11 (1966) 394–397. [11] H. Schonhorn, Surface treatment of polymers for adhesive bonding, J. Chem. Eng. Data 12 (1967) 524–525. [12] M. Zheng, J. Tian, A. Mulero, A., F., New correlations between viscosity and surface tension for saturated normal fluids, Fluid Phase Equilib. 360 (2013) 298–304. [13] M.H. Ghatee, M. Zare, A.R. Zolghadr, F. Moosavi, Temperature dependence of viscosity and relation with the surface tension of ionic liquids, Fluid Phase Equilib. 291 (2010) 188–194. [14] M. Oroian, Measurement, prediction and correlation of density, viscosity, surface tension and ultrasonic velocity of different honey types at different temperatures, J. Food Eng. 119 (2013) 167–172. [15] P.K. Banipal, V. Singh, N. Aggarwal, T.S. Banipal, Hydration behaviour of some mono-, di-, and tri-saccharides in aqueous sodium gluconate solutions at (288.15, 298.15, 308.15 and 318.15) K: volumetric and rheological approach, Food Chem. 168 (2012) 142–150. [16] S. Nithiyanantham, L. Palaniappan, Ultrasonic study on some monosaccharides in aqueous media at 298.15 K, Arab. J. Chem. 5 (2012) 25–30. [17] G.O. Hernandez-Segura, M. Campos, M. Costas, L.A. Torres, Temperature dependence of the heat capacities in the solid state of 18 mono-, di-, and poly-saccharides, J. Chem. Thermodyn. 41 (1) (2009) 17–20. [18] N. Auerbach, Oberflächenspannung und Schallgeschwindigkeit, Experientia 4 (1948) 473–474.