Uploaded by

common.user23005

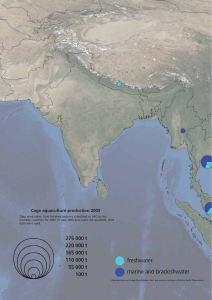

Aquaculture Operations in Floating HDPE Cages: FAO Field Handbook

advertisement