Uploaded by

common.user8305

Optimum Development in Mature Oil Fields: Sanga-Sanga Case Study

advertisement

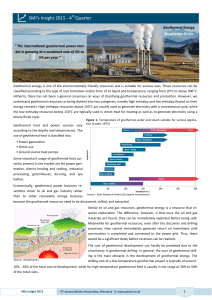

Optimum Development in Mature Fields: Sanga-Sanga Assets, Indonesia V ICO Indonesia is the operator of the Sanga-Sanga productionsharing contract (PSC) in Indonesia. Against a backdrop of of 46% annual base decline, VICO generated and implemented an integrated and aggressive work program called the Renewal Plan. This is an integrated approach between reservoir management and technology application. This plan proved to be an efficient example of better reservoir management for optimum development of mature assets. monobore, and horizontal). The surface facilities supporting the production include four main production centers, 12 gathering stations, and more than 90 compressors. After 40 years of production, these fields have now reached a fairly mature stage; most of the penetrated reservoirs/ tanks have been depleted from original pressures. Coupled with the annual production decline, this condition has resulted in significant challenges to delivering a continuous economic and efficient field-development strategy while maximizing field production. Introduction Renewal Plan The Sanga-Sanga acreage is located onshore in the Mahakam delta, East Kalimantan, Indonesia. The acreage is located within the Kutai basin, which is characterized by the Samarinda anticlinorium, with a series of highly prolific anticlines. Hydrocarbon accumulations are most often located within a series of mid-Miocene upper-delta and delta-plain sandstone reservoirs, and are principally characterized by fourway dip closure or two-way structural/ stratigraphic traps. VICO Indonesia has been exploring and developing this PSC acreage actively since 1968. There are seven producing fields (Fig. 1): Badak, Nilam, Semberah, Mutiara, Beras, Pamaguan, and Lampake. These together produce 385 MMscf/D of gas and 14,500 B/D of liquids from 420 active wells, which have mixed wellbore completions (single, d ­ual-selective, monobore, dual- VICO carried out a reserves-reassessment study—an integrated approach involving reservoir management and technology applications conducted by a multidisciplinary team. The seven components of the Renewal Plan are described in the following subsections. Securing Base Production. Securing base production is one of the keys to achieving a production target. Well monitoring and surveillance are the primary methods by which base production is secured. Previously, VICO wells were monitored by frequent production tests, mostly depending on human surveillance. In the Renewal Plan, automated ­real-time monitoring well surveillance of wellhead-pressure and flow-rate data on each well was impemented. This ­real-time wellhead surveillance (RTWHS) transmits the data from the wellsite to This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper SPE 158716, “Renewal Plan: Efficient Strategy for Optimum Development in Mature Fields—A Success Story From Sanga-Sanga Assets, Indonesia,” Andre Wijanarko, Bambang Ismanto, and Robhy Permana, VICO Indonesia, and Italo Pizzolante, Eni, prepared for the 2012 SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 22–24 October. The paper has not been peer reviewed. the VICO server; then, it is stored in a data­base. Operators and production engineers could monitor the behavior of the well in real time. This system has proved to minimize well downtime, leading to aggressive well reactivation. This installation has also become standard for new wells. Currently, 90% of VICO’s active wells are equipped with RTWHS. Aggressive Drilling Plan. The multidisclipinary team concluded that remaining potential reserves are high, even though the PSC acreage has produced 70% over 40 years. New well development can be carried out by means of ­conventional-well, grid-based-drilling, and cluster-drilling methods. Previous VICO completion design used single-/dual-string 2⅞-, 2⅜-, and 3½-in. completion with multipackers installed for single/multiple perforation. This led to commingled production from several zones, reducing the maximimum potential of each individual zone. The single 4½-in. monobore offered better reservoir management and a single production tubing, with the annulus cemented up to surface. The downside of the 4½-in.-monobore completion, however, includes less flexibility to catch up with the deliverability target. A dual 3½-in.-monobore completion was implemented, and flexibility of the production strategy was achieved by use of long strings for maximizing reserves recovery, and short strings for optimizing production. This dual 3½‑in. monobore has become a standard well completion in VICO Indonesia’s portfolio. Aggressive Rigless Development. While maintaining base production, optimization of existing wells is the priority for meeting the production target. To that end, on a routine basis, the multi­ For a limited time, the complete paper is free to SPE members at www.spe.org/jpt. 86 MFW158716.indd 86 JPT • JANUARY 2014 12/12/13 1:37 PM 1600 Compress to VLP Compress With Wellhead Compressor 275 1400 250 225 1200 200 Gas, Mcf/D 1100 1000 175 900 150 800 125 700 100 600 500 75 400 50 300 25 200 20 km 0 1/9/07 1/10/07 1/11/07 1/12/07 1/1/08 1/2/08 1/3/08 1/4/08 1/5/08 1/6/08 1/7/08 1/8/08 1/9/08 1/10/08 1/11/08 1/12/08 1/1/09 1/2/09 1/3/09 1/4/09 1/5/09 1/6/09 1/7/09 1/8/09 1/9/09 1/10/09 1/11/09 1/12/09 1/1/10 1/2/10 1/3/10 1/4/10 1/5/10 1/6/10 1/7/10 1/8/10 1/9/10 1/10/10 10 Gas, Mcf/D Fig. 1—Sanga-Sanga PSC. disciplinary team evaluated potential wells along with underperforming wells, idle wells, and bypassed zones. For underperforming wells, a detailed review was conducted to determine the causes of production decline. Static/ flowing bottomhole and productionlogging data are useful in this task; nodal-analysis and material-balance software were used to support review findings. For idle wells, a detailed review is performed to evaluate existing producing zones and remaining potential zones. A bypassed zone is a potential productive zone that was not interpreted as a hydrocarbon zone in the past. These zones are reviewed on the basis of log data, offset-well production, and mudlog data compiled during drilling. Low-Permeability Exploitation. One of the Renewal Plan objectives is to regain production and increase the reserves recovery from low-permeability zones. Because most of the fields have reached a mature stage at which the shallow and middle layers have been 88 MFW158716.indd 88 Flowing Tubinghead Pressure, psig 1300 0 300 1500 Date Flowing Tubinghead Pressure, psig Fig. 2—Wellhead compressor. produced and depleted significantly, the remaining reserves are spread over the deeper low-permeability sands, where previous completion approaches have not effectively depleted the reserves. A comprehensive approach was identified that ranks the candidate reservoirs for low-permeability development. Additionally, several low-­permeability gas-development strategies and technologies have been evaluated and executed since 2006. These low-­permeability technology ­ applications pertained to horizontal wells, hydraulic fracturing, and radial drilling/jetting. Deliquification. A large proportion of VICO’s existing well production is subject to liquid loading, leading to premature abandonment of producing zones; and some wells have to be in cyclic production. Liquid loading of a gas well is the inability of produced gas to remove the produced liquids from the wellbore, leading to excessive backpressure on the production interval, which in turn reduces productivity. This situation is influenced by tubing size, sur- face pressure, and the amount of associated liquids being produced with the gas. Historically, VICO’s approach to well reactivation/deliquification included low-cost, low-technology solutions such as venting, cycling, gas injection, and soap sticks, used with mixed success. In 2006, in new-technology trials, the installation of capillary-string injection in liquid-loaded wells was tested. The capillary-string-injection concept introduces a foaming agent into the wellbore through ¼-in. capillary strings and injects the surfactant across the perforation. The foaming agent is then mixed with produced fluids, reducing the density of the liquid, increasing the gas velocity, and improving the ability of the well to produce liquids and have stabilized gas flow. This capillarystring chemical injection was chosen because its relatively simple application also can be implemented in a wide range of VICO’s completions (monobores, dual-string completions with nipple profiles, and selective completions produced through sliding sleeves). JPT • JANUARY 2014 12/12/13 1:37 PM Fieldwide capillary-string-injection installation has been implemented since 2006. Currently, there are 65 capillarystring-injection installations, which have successfully maintained ­liquid-loaded-well production with continuous flow (instead of a cyclic mode) to deliver 16 MMscf/D. Oil Development. The aggressive drilling program in Mutiara and Pamaguan fields resulted in an increase of oil reservoirs to be produced. A gas lift system is the preferred method used to achieve artificial lift because VICO has abundant gas resources. Because monobore wells have no annulus (they are cemented up to surface), there is no gas-lift-valve/side-pocket-mandrel configuration available to introduce gas lift into the production tubing. A solution for developing oil in a monobore well completion involves use of smaller-inside-diameter coiled tubing (normally 1½-in. diameter) inside the production tubing, which includes special bottomhole assemblies (nozzle, ­dual-flapper check valve, and nipple). A special tubing hanger is attached to the top of the tree to hold the inserted coiled tubing. This application is known as permanent-coiled-tubing gas lift (PCTGL), which allows gas lift injection into the production tubing. This method does not require the well to be recompleted with a rig, thus having significant cost savings and delivering desired oil production. During 2010–2011, 16 units of PCTGL were installed, successfully sustaining 3,500 B/D of oil production. Facility Optimization. To maximize reserves recovery with the condition that most of the production comes from depleted reservoirs, several attempts to lower abandonment pressure were made. Lowering the flowing wellhead pressure will keep the well flow above the critical and liquid-loaded rates for a longer period of time. To assist in this effort, VICO has categorized four different pressure systems: 1. High-pressure compressor with an inlet pressure of 700 psi and an outlet pressure of up to 1,500 psi 2. Medium-pressure compressor with an inlet pressure of 280 psi and an outlet pressure of up to 710 psi 3. Low-pressure compressor with an inlet pressure of 100 psi and an outlet pressure of up to 320 psi 4. Very-low-pressure (VLP) compressor with an inlet pressure of 25 psi and an outlet pressure of up to 120 psi Before 2006, only a few VLP compressors were available. Consequently, some of the wells prematurely ceased flowing because of an inability to flow in lower-pressure systems. Several studies were performed to determine how to lower fieldabandonment pressure, improve well productivity and reserves, and better manage a gas field’s natural decline. These studies resulted in additional VLP compressors and indeed in the categorization of another compressor with pressure lower than that of a VLP system—called an extreme-low-pressure compressor (wellhead compressor). Having wellhead compressors installed at the wellsite reduces the flowing wellhead pressure further (Fig. 2). JPT JPT • JANUARY 2014 MFW158716.indd 89 89 12/12/13 1:36 PM