Uploaded by

mcqueenklarencrownsher

Synthesis of InSn Alloy Superconductor Below Room Temperature

advertisement

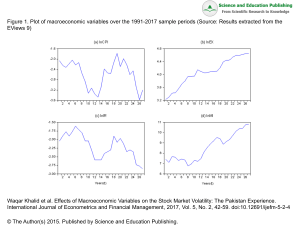

Accepted Manuscript Synthesis of InSn alloy superconductor below room temperature Takashi Mochiku , Minoru Tachiki , Shuuichi Ooi , Yoshitaka Matsushita PII: DOI: Reference: S0921-4534(18)30347-2 https://doi.org/10.1016/j.physc.2019.04.002 PHYSC 1253474 To appear in: Physica C: Superconductivity and its applications Received date: Revised date: Accepted date: 24 September 2018 7 April 2019 8 April 2019 Please cite this article as: Takashi Mochiku , Minoru Tachiki , Shuuichi Ooi , Yoshitaka Matsushita , Synthesis of InSn alloy superconductor below room temperature, Physica C: Superconductivity and its applications (2019), doi: https://doi.org/10.1016/j.physc.2019.04.002 This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain. ACCEPTED MANUSCRIPT Highlights: A GaInSn eutectic alloy exhibits superconductivity at 6.0 K. An In3Sn superconductor formed below 260 K from the GaInSn liquid alloy. Superconducting films can be fabricated by coating the substrate with CR IP T AC CE PT ED M AN US the alloy. ACCEPTED MANUSCRIPT Synthesis of InSn alloy superconductor below room temperature Takashi Mochikua,*, Minoru Tachikib, Shuuichi Ooib, Yoshitaka Matsushitac a Research Center for Advanced Measurement and Characterization, National Institute b Research Center for Functional Materials, National Institute for Materials Science, 1-2-1 Sengen, Tsukuba, Ibaraki 305-0047, Japan Research Network and Facility Services Division, National Institute for Materials AN US c CR IP T for Materials Science, 1-2-1 Sengen, Tsukuba, Ibaraki 305-0047, Japan Science, 1-2-1 Sengen, Tsukuba, Ibaraki 305-0047, Japan M * Corresponding author: Takashi Mochiku PT Abstract ED E-mail address: [email protected] CE The eutectic point for a typical gallium indium tin (GaInSn) alloy with an atomic composition of 78% Ga, 15% In, and 7% Sn is at near room temperature. This alloy AC exists in the liquid state at room temperature and solidifies below 260 K. We found that the major In3Sn and minor InSn4 superconducting phases are formed in this liquid alloy below 260 K and this alloy exhibits superconductivity at 6.0 K. Therefore, we can fabricate superconducting thick films without heat treatment by simply coating a substrate with the alloy and subsequently cooling it to the alloy’s superconducting ACCEPTED MANUSCRIPT transition temperature. CR IP T Keywords: In3Sn; InSn4; GaInSn; superconductor; eutectic alloy 1. Introduction Several methods for fabricating superconducting films, such as sputtering, AN US electron-beam evaporation, pulsed-laser deposition, and chemical vapor deposition, have been developed. These methods require a high-vacuum apparatus and film deposition procedures are time consuming. However, in recent years, the fabrication of M superconducting films using a coating process has been extensively studied for ED commercial applications [1] and films with a large area have been easily and quickly fabricated without the need of a high-vacuum apparatus. Heat treatment is required after PT the selected substrate is coated with a solution. If the superconducting phase is grown CE from a solution below room temperature, superconducting films can be synthesized by simply coating the substrate with a solution and subsequently cooling it to its AC superconducting transition temperature (Tc) without applying heat treatment. Since this method simplifies the fabrication of superconducting films, several applications of coated superconductors are expected. Possible applications include coated conductors for large-scale superconducting components (e.g., superconducting wires, coils, and cavities), superconducting connections for these components, superconducting ACCEPTED MANUSCRIPT nanowires sheathed in carbon nanotubes [2], microstructural superconductors poured into mesoporous materials, and printable superconducting devices. Herein, we have focused on an alloy of gallium (Ga) and a superconductor CR IP T comprising indium (In) and tin (Sn) [3,4] because the eutectic point of GaIn and GaSn alloys is near room temperature [5,6]. The eutectic point of the GaInSn alloy is also near room temperature. With a specific composition, this alloy exists as a liquid at room AN US temperature [7] and is commercially used as a replacement for mercury (Hg) in thermometers. Several reports have investigated the fabrication methods and the flexible and reconfigurable electronics applications of microstructured Ga-based liquid alloys M including the GaInSn alloy [8]. Ren et al. [9] reported that GaInSn nanodroplets exhibit ED superconductivity at 6.6 K and the Ga, In, and Sn crystalline phases are formed below 133 K. Herein, we report that the major In3Sn and minor InSn4 superconducting phases PT can be formed from this liquid alloy by cooling the alloy-coated substrate below 260 K CE and that the alloy exhibits superconductivity at 6.0 K. Although Hg also exists in liquid form at room temperature and exhibits superconductivity, its toxicity and high AC vapor pressure limit its use in practical applications. The GaInSn alloy does not possess these limitations and thus can expand the range of applications. 2. Material and methods The samples were prepared by mixing Ga (99.999% purity), In (99.999% purity) ACCEPTED MANUSCRIPT and Sn (99.999% purity) in an atomic ratio of 78:15:7 at ~300 K on a hot plate. The atomic ratio of the mixture was determined by assessing the eutectic point of the GaIn and GaSn systems [5,6]. Since the eutectic point for the GaInSn alloy with the CR IP T aforementioned ratio is at near room temperature, the mixture melts at ~300 K. A horizontal sample mount X-ray diffractometer (Rigaku SmartLab 9 kW) with a cryostat system and Cu K radiation was used to collect X-ray diffraction (XRD) data from 5 AN US to 300 K. The samples were placed on a Cu holder coated with Apiezon N grease. Before conducting the intensity measurements, the samples were cooled to 5 K at a rate of 30 K/min and were maintained at 5 K for 12 h to achieve a uniform temperature M distribution. Subsequently, the samples were heated from 5 to 300 K at a rate of 5 ED K/min and then cooled from 300 to 200 K at a rate of 5 K/min. The intensity data were collected after the temperature was maintained for 15 min at each target temperature. PT The microstructure of the samples from 233 to 290 K was observed with a polarizing CE microscope using a liquid helium sample cooling stage for the samples, which were placed between cover slips. Electrical resistivity was measured using the standard AC four-probe method for a coated specimen, which was ~8 × 2 mm2 in size, on a glass substrate. Magnetization measurements were conducted using a superconducting quantum interface device magnetometer (Quantum Design Magnetic Property Measurement System). ACCEPTED MANUSCRIPT 3. Results and discussion The XRD patterns indicate that the samples were in liquid form at 300 K and that the In3Sn phase formed below 260 K (Fig. 1 (k)) and melted above 280 K (Fig. 1 (g)). The CR IP T minor InSn4 phase formed and melted at the same temperature as the major In3Sn phase. The freezing temperature was lower than the melting temperature because liquid Ga showed the supercooling behavior. No change in the XRD patterns was observed at AN US temperatures below 250 K. Because the Ga grains at certain orientations formed according to the rate of temperature change, differences were observed between the XRD patterns collected during the warming and cooling processes at 200 K (Figs. 1 (e) M and (l)). These behaviors differ from those of the Ga, In, and Sn crystallization phases in ED the GaInSn nanodroplets [9] because a conventional eutectic reaction occurs in the proposed bulk GaInSn alloys. Figure 2 shows the microstructure for the sample at 290 PT K and 233 K. Dark filamentous textures were observed at 233 K, indicating the growth AC CE of the In3Sn and InSn4 phases in the Ga matrix. CE PT ED M AN US CR IP T ACCEPTED MANUSCRIPT AC Figure 1. Observed XRD patterns for the GaInSn alloy at (a) 10, (b) 50, (c) 100, (d) 150, (e) 200, (f) 250, (g) 280, (h) 290, (i) 300, (j) 270, (k) 260, and (l) 200 K. The circle, rhombic and inverted triangle symbols indicate the Bragg reflections due to the Ga, In3Sn and InSn4 phases, respectively. AN US CR IP T ACCEPTED MANUSCRIPT M Figure 2. Polarizing microscope images for the GaInSn alloy at (a) 290 and (b) 233 K. ED The dark speckles are caused due to the presence of fine dust on the surface of the cover AC CE PT slips. ACCEPTED MANUSCRIPT Figure 3 shows the electrical resistance and temperature characteristics of the sample. We observed zero resistance at 6.0 K when the temperature was increased or decreased, indicating that the In3Sn phase exhibits superconductivity. This observation CR IP T can be attributed to the fact that the Tc value for the minor InSn4 phase is lower than that for the In3Sn phase [3]. A difference was observed between the electrical resistances during the cooling and warming processes with a jagged behavior observed during the AN US cooling process. This behavior changed every time the resistance was measured; however, the Tc value remained almost constant. The resistance is possibly dependent on the changing temperature of the sample during cooling and warming. A sharp M decrease in resistance was observed at 261 and 287 K during the cooling and warming ED processes, respectively. These decreases in resistance are consistent with the freezing AC CE PT and melting temperatures observed in the XRD measurements. CE PT ED M AN US CR IP T ACCEPTED MANUSCRIPT Figure 3. Temperature dependence of electrical resistivity for the GaInSn alloy. The AC applied current was 10 mA. ACCEPTED MANUSCRIPT Figure 4 shows that the samples exhibit bulk superconductivity below 5.8 K, which is consistent with the Tc value obtained from the electrical resistance measurements. The lower and upper critical fields, Hc1 and Hc2, were determined from the magnetization CR IP T measurement results. These values are shown as a function of temperature in Fig. 5. We determined the Hc1(0) and Hc2(0) values as 205 and 3561 Oe, respectively, using the following formula: AN US Hc(T) = Hc(0)[1 − (T/Tc)2], where Hc(0) is Hc at 0 K. The Hc1(3) value for the samples (148 Oe) is lower than that of bulk In3Sn (200 Oe) and the Hc2(3) value for the samples (2574 Oe) is higher than M that of bulk In3Sn (1700 Oe) [10]. We assumed that the deviation in the composition ED from a stoichiometric composition and the formation of a eutectic structure led to the AC CE PT difference between the Hc(3) values for the samples and those for the bulk In3Sn. CE PT ED M AN US CR IP T ACCEPTED MANUSCRIPT AC Figure 4. Temperature dependence of zero-field-cooled magnetization for the GaInSn alloy at 10 Oe. CE PT ED M AN US CR IP T ACCEPTED MANUSCRIPT AC Figure 5. Temperature dependence of the lower and upper critical fields, Hc1 and Hc2, respectively, for the GaInSn alloy. The lines represent the result of fitting the experimental data to the formula Hc(T) = Hc(0)[1 − (T/Tc)2]. ACCEPTED MANUSCRIPT Figure 6 shows the dependence of the superconducting transition for the Ga78In22−xSnx alloy on the atomic composition, x. The sample with x = 7 (an atomic ratio of 78:15:7) has a higher Tc value and narrower superconducting transition than CR IP T those for other samples. Its composition is shifted from the stoichiometric composition (x = 5.5) which corresponds to In3Sn. Although the Tc value is similarly higher at the composition shifted from the stoichiometric composition in the bulk In3Sn [3], the Tc AN US value of the sample with x = 7 is lower than the highest Tc value (6.60 K) of the bulk In3Sn [3], and the superconducting transition width is broader than that of the bulk In3Sn [3]. The composition of the In3Sn phase in the GaInSn alloy may differ from that M of the bulk In3Sn with the highest Tc value and the composition distribution. The sample AC CE PT ED with x = 17.6, which corresponds to InSn4, did not melt at ~300 K. CE PT ED M AN US CR IP T ACCEPTED MANUSCRIPT Figure 6. Temperature dependence of zero-field-cooled magnetization for the AC Ga78In22−xSnx alloy at 10 Oe. The magnetization M/M(2K) is normalized by the value of the magnetization at 2 K. ACCEPTED MANUSCRIPT 4. Conclusions Herein, we found that the InSn alloy superconductor with a Tc value of 6.0 K was formed from the GaInSn eutectic alloy, with an atomic ratio of 78:15:7, below 260 K. CR IP T Therefore, superconducting thick films can be fabricated without applying heat treatment simply by coating the substrate with the alloy and subsequently cooling it to its Tc. The Hc1(0) and Hc2(0) values were estimated to be 205 Oe and 3561 Oe, AC CE PT ED M AN US respectively, and these values differed from those of the In3Sn bulk. ACCEPTED MANUSCRIPT References [1] T. Arai, Bull. Chem. Soc. Jpn. 77 (2004) 1051. https://doi.org/10.1246/bcsj.77.1051. [2] N. Jeong and J. Yeo, Nanotech. 23 (2012) 285604. CR IP T https://doi.org/10.1088/0957-4484/23/28/285604. [3] M. F. Merriam and M. Herzen, Phys. Rev. 131 (1963) 637. https://doi.org/10.1103/PhysRev.131.637. AN US [4] S. F. Bartram, W. G. Moffatt, and B. W. Roberts, J. Less-Common Met. 62 (1978) 9. https://doi.org/10.1016/0022-5088(78)90011-5. [5] T. J. Anderson and I. Ansara, J. Phase Equilibria 12 (1991) 64. M https://doi.org/10.1007/BF02663677. ED [6] T. J. Anderson and I. Ansara, J. Phase Equilibria 13 (1992) 181. https://doi.org/10.1007/BF02667485. PT [7] N. B. Morley, J. Burris, L. C. Cadwallader, and M. D. Nornberg, Rev. Sci. Instr. 79 CE (2008) 056107. https://doi.org/10.1063/1.2930813. [8] M. A. Khondoker, D. Sameoto, Smart Mater. Struct. 25 (2016) 093001. AC https://doi.org/10.1088/0964-1726/25/9/093001. [9] L. Ren, J. Zhuang, G. Casillas, H. Feng, Y. Liu, X. Xu, Y. Liu, J. Chen, Y, Du, L. Jiang, and S. X. Dou, Adv. Funct. Mater. 26 (2016) 8111. https://doi.org/10.1002/adfm.201603427. [10] R. Kubiak, M. Wolcyrz, and W. Zacharko, J. Less-Common Met. 65 (1979) 263. ACCEPTED MANUSCRIPT AC CE PT ED M AN US CR IP T https://doi.org/10.1016/0022-5088(79)90116-4.